GBC 1264WF/1244WF Operation Manual

© 2006 General Binding Corporation Page 28

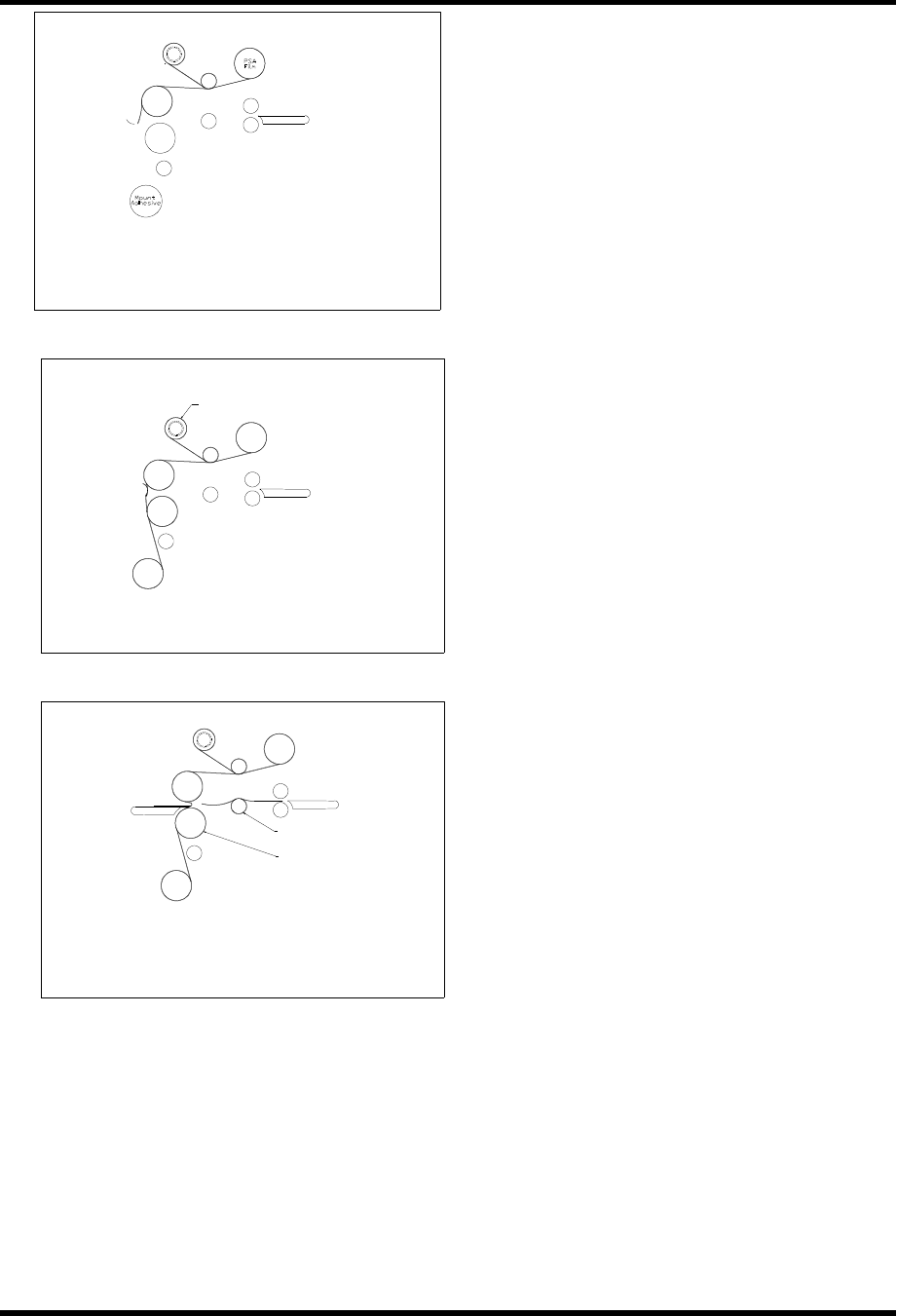

Fig. 6

Fig. 7

Fig.8

Webbing PSA Film/Mount Adhesive Using Threading

Card

The laminator should be cool to the touch before

Proceeding.

1. Turn the Power ON /OFF to On

2. Load the rolls of film as illustrated in (Fig. 6). Ensure

no brake tension is applied to the film shafts.

3. Pull the top roll of film down under the idler bar and

up to the upper front rewind tube.

4. Place one piece of masking tape in the center of the

film and secure to the rewind tube.

5. Make two full wraps around the rewind tube, and then

score the laminate without cutting the release liner.

Pull the laminate down allowing it to drape over the

upper roller (Fig. 6).

6. Pull the mount adhesive up towards the film draped

over the upper heat roller (Fig.7).

7. Stick the mount adhesive to the exposed adhesive of

the upper role.

8. Insert the table back to its feeding position while

ensuring the threading card is on top of the feed table

(Fig. 8).

9. Use a threading card to push the two materials through

the heat roller nip

10.Lower the main heated roller to bring the main roller

into initial contact with the threading card. Ensure

front is selected and press the foot switch.

11.From the rear of the machine, guide the web over the

chill idler, if installed, and through the pull rollers.

Once the web has entered the pull roller nip, close the

pull roller nip –

12.Press the stop button when the threading card has

completely exited the pull rollers and adjusts the film

web tension using as little tension as possible.

13.Now refer to the section titled START

LAMINATING.

REWIND TUBE

Adhesive

Mount

Film

PSA

HEAT ROLLER

CHILLED ROLLER

Adhesive

Mount

Film

PSA