2

Section 1 — General Information

ATS “HS” Type Transfer Switch

1.1 INTRODUCTION

This manual has been prepared especially for the

purpose of familiarizing personnel with the design,

application, installation, operation and servicing of

the applicable equipment. Read the manual carefully

and comply with all instructions. This will help to

prevent accidents or damage to equipment that might

otherwise be caused by carelessness, incorrect appli-

cation, or improper procedures.

Every effort has been expended to make sure that the

contents of this manual are both accurate and cur-

rent. The manufacturer, however, reserves the right

to change, alter or otherwise improve the product at

any time without prior notice.

1.2 EQUIPMENT DESCRIPTION

The automatic transfer switch is used for transfer-

ring electrical load from a UTILITY (NORMAL) power

source to an EMERGENCY (STANDBY) power source.

Such a transfer of electrical loads occurs automati-

cally when the UTILITY power source has failed or is

substantially reduced and the EMERGENCY source

voltage and frequency have reached an acceptable

level. The transfer switch prevents electrical feedback

between two different power sources (such as the

UTILITY and EMERGENCY sources) and, for that

reason, codes require it in all standby electric system

installations.

The transfer switch consists of a transfer mecha-

nism, service disconnect circuit breaker, a relay

control, fuses, and a terminal strip for connection of

sensing wires.

This transfer switch is suitable for use as service

entrance equipment.

1.2.1 TRANSFER SWITCH MECHANISM

These switches (Figure 1.1) are used with a single-

phase system, when the single-phase NEUTRAL line

is to be connected to a Neutral Lug and is not to be

switched.

Solderless, screw-type terminal lugs are standard.

Switch Wire Conductor Tightening

Rating Range Torque

100A #14-1/0 AWG 50 in-lbs.

200A #6-250 MCM 275 in-lbs.

This transfer switch is suitable for control of motors,

electric discharge lamps, tungsten filament and elec-

tric heating equipment where the sum of motor full

load ampere ratings and the ampere ratings of other

loads do not exceed the ampere rating of the switch

and the tungsten load does not exceed 30 percent of

the switch rating.

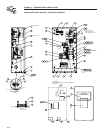

Figure 1.1 — Typical ATS Transfer Mechanism

UTILITY

CLOSING

COIL

GENERATOR

CLOSING

COIL

UTILITY LUGS

GENERATOR

LUGS (E1 & E2)

LOAD LUGS (T1 & T2)

This transfer switch is for use in optional standby

systems only.

This transfer switch is suitable for use on a circuit

capable of 10,000 rms symmetrical amperes, 240

VAC maximum.

1.2.2 SERVICE DISCONNECT CIRCUIT

BREAKER

The service disconnect circuit breaker for the 100

amp models are:

• Siemens, Type BQ, 2-pole

• 120/240VAC, 100A

• 50/60 Hertz

• Heating, Air Conditioning and Refrigeration (HACR)

rated

• Wire range: #1 - #8 AWG.

• The conductor tightening torque is 50 in-lbs.

The service disconnect circuit breaker for the 200

amp models are:

• Siemens, Type QN, 2-pole

• 120/240VAC, 200A

• 50/60 Hertz

• Heating, Air Conditioning and Refrigeration (HACR)

rated

• Wire range: 300 KCMIL - 4 AWG

• The conductor tightening torque is 250 in-lbs.

1.3 TRANSFER SWITCH DATA DECAL

A DATA DECAL is permanently affixed to the transfer

switch enclosure. Use this transfer switch only with

the specific limits shown on the DATA DECAL and

on other decals and labels that may be affixed to the

switch. This will prevent damage to equipment and

property.