6 308703

Installation

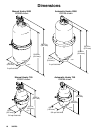

The installations in Fig. 2 are guides for selecting and installing system components. Contact your Graco distributor

for assistance in planning a system to suit your needs.

Mounting Automatic and Manual Models

Be sure the mounting surface can support the weight of the pump, surge suppressor, hoses, and accessories, and

the stress caused during operation.

D Mount the surge suppressor as close to the pump discharge as possible and upstream of equipment such as

valves, meters, filters, and so on. The surge suppressor should be installed within 10 pipe diameters of the

pump discharge.

D If you use a flexible connector from the pump to the piping system, the surge suppressor should be mounted to

the pump discharge manifold, and the flexible connector should be attached to the surge suppressor tee and

system piping.

D Because pressure is equal in all directions, the surge suppressor can be installed in any position, but the vertical

position shown in Fig. 2 is recommended for better draining. Fluids with high specific gravity or high viscosity,

settling of heavy material, and possible air entrapment further limit the mounting positions other than those

shown in Fig. 2.

NOTE: When you mount a plastic surge suppressor, do not overtighten by using a large pipe wrench near the

threads of the fluid inlet. The housing may crack if tightened too much. Hand tightening is recommended.

Connecting Automatic Models

D Connect the 1/4-in air supply hose to the 1/4 npt

connection on the top of the surge suppressor.

D The air pressure to the surge suppressor must be

greater than or equal to the pump discharge and/or

system pressure. For equal air pressure, you can

use a tee in the pump’s air supply line to run an air

line to the surge suppressor.

D For models with elastomer bladders, the tee must

be located in the pump’s air supply line before any

pump controller or instrumentation such as the

filter, regulator, or pump control valve.

D For models with PTFE bellows, the tee must be

located in the pump’s air supply line after any pump

controller or instrumentation such as the filter,

regulator, or pump control valve.

Connecting Manual Models

D Connect the 1/4-in air supply hose to the brass

one-way check valve on the top of the surge sup-

pressor.

D The air pressure to the surge suppressor must be

greater than or equal to the pump discharge and/or

system pressure. For equal air pressure, you can

use a tee in the pump’s air supply line to run an air

line to the surge suppressor.

D The tee must be located in the pump’s air supply

line before any pump controller or instrumentation

such as the filter, regulator, or pump control valve.