TP-6810 11/13 53Section 4 Scheduled Maintenance

4.7 Ignition System

Service the spark plugs at the interval specified in the

service schedule using the following procedure.

1. Press the OFF button on the RDC2 controller.

2. Disconnect the power to the battery charger.

3. Disconnect the generator set engine starting

battery, negative (--) lead first.

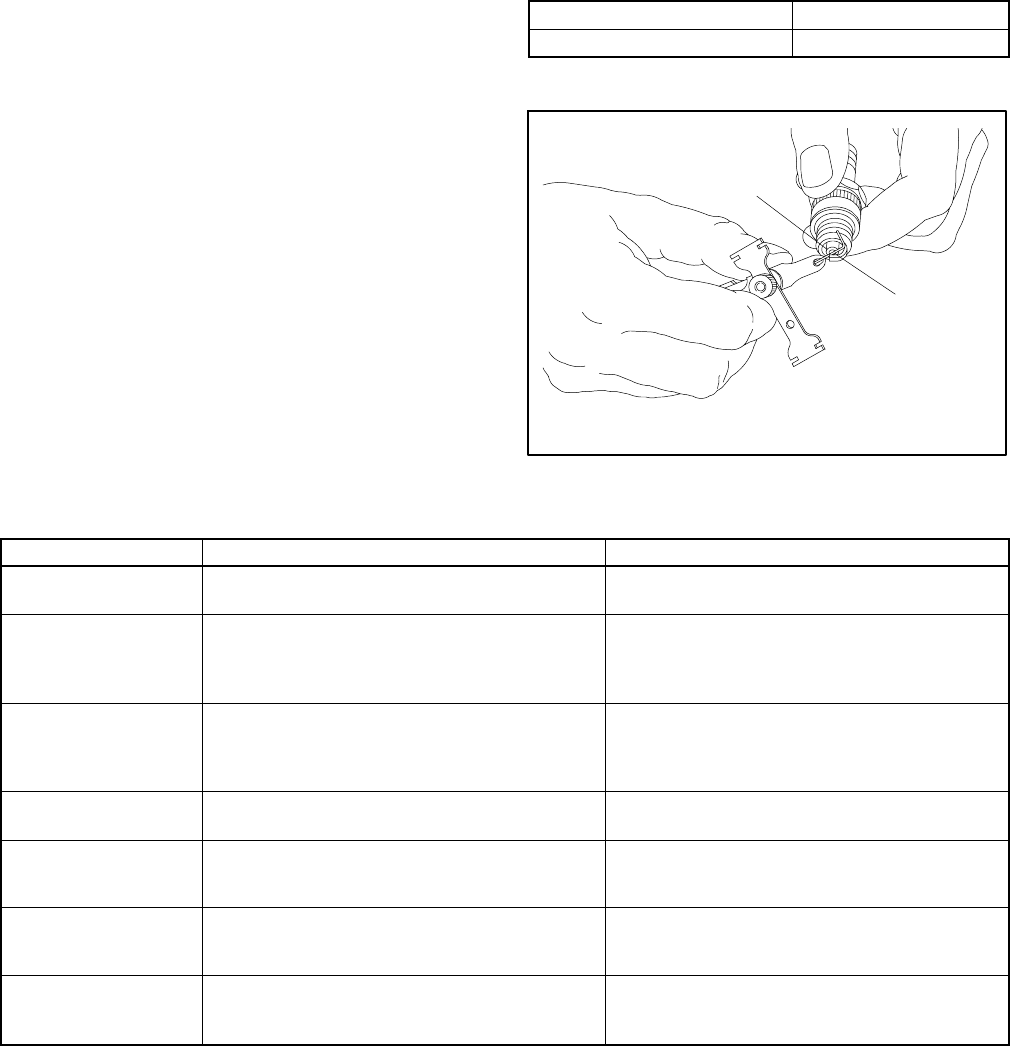

4. Remove spark plug wires by grasping the spark

plug boot and turning slightly while pulling. Do not

pull the wire. Pulling on the wire rather than the

boot may damage the wire or terminal.

5. Loosen the spark plug with a ratchet and 5/8-in.

spark plug socket with a rubber insert to prevent

spark plug damage.

6. Use compressed air to remove dirt from around

each sparkplug to prevent dirtparticles from falling

into the combustion chamber.

7. Remove spark plugs, one at a time, and examine.

Identify a normal spark plug in good operating

condition by observing a light tan or gray deposit on

firing tip. See Figure 4-9 to evaluate engine

condition bycolor/condition of aproblem spark plug.

8. Clean spark plugs by wiping them with a rag. File

the center electrode to keep it parallel to the side

electrode.

Note: Do not sandblast, wire brush, scrape, or

otherwise service spark plugs in poor

condition. Obtain a new plug for best

results.

9. Check the spark plug gap before installing any

spark plug. See Figure 4-7 and Figure 4-8. Attain

a correct gap when the feeler (or wire) passes

between the spark plug electrode. It should pass

easily but with some resistance or drag; otherwise

adjust as necessary.

Model Spark plug gap

38 RCL, 48RCL, and 60RCL 0.9 mm (0.035 in.)

Figure 4-7 Recommended Spark Plug Gap

1-514

1

2

1. 0.9 mm (0.035 in.) gap

2. Spark plug electrodes

Figure 4-8 Spark Plug Gap Inspection

Problem/Condition Means of Identification Possible Cause/Solution

Gap-bridged spark

plug

Built-up deposits and gap between electrodes

closing.

Oil or carbon fouling. Clean and regap the spark

plug.

Oil-fouled spark plug Wet, black deposits on the insulator shell, bore,

and electrodes.

Excessive oil entering combustion chamber

through worn rings and pistons, excessive

clearance between valve guides and stems, or

worn or loose bearings. Replace the spark plug.

Carbon-fouled spark

plug

Black, dry, fluffy carbon deposits on insulator

tips, exposed shell surfaces and electrodes.

Incorrect spark plug, weak ignition, clogged air

intake, overrich fuel mixture, or excessive

no-load operation. Clean and regap the spark

plug.

Lead-fouled spark plug Dark gray, black, yellow, or tan deposits; or a

glazed coating on the insulator tip.

Caused by highly leaded fuel. Replace the

spark plug.

Pre-ignition damaged

spark plug

Melted electrodes and possibly blistered

insulator. Metallic deposits on i nsulator suggest

internal engine damage.

Wrong type of fuel, incorrect timing or advance,

too hot a plug, burned valves, or engine

overheating. Replace the spark plug.

Overheated spark p lug White or light gray insulator with small black or

gray/brown spots with bluish (burned)

appearance on electrodes.

Engine overheating, wrong type of fuel, loose

spark plugs, too hot a plug, low fuel pressure or

incorrect ignition timing. Replace the spark plug.

Worn spark plug Severely eroded or worn electrodes. Caused by normal wear and failure to replace

spark plug at prescribed interval. Replace the

spark plug.

Figure 4-9 Engine Evaluation Using Spark Plug Condition