General Information 1-11

5016-001

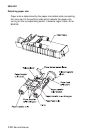

Paper Feed Unit

Operation of the paper feed unit (tray 1)

When the paper cassette (tray 1) is present in the printer, a flag

molded in the right side of the tray contacts the release lever rotating

the paper transfer roll, allowing it to contact the paper in the tray.

When a print command is sent to the printer, the paper feed clutch,

attached to the paper feed roller turns on, which turns the main

motor transmitting to the clutch gear magnet and the paper feed

gears, causing the paper feed roller and paper transfer roller to turn.

Double feed prevention

The double feed prevention pad contacts the sheet bypass paper

feed roller at a specific pressure.

Whenever multiple sheets of paper are fed, the bottom sheet is

stopped by friction of the double feed prevention pad which aids in

the prevention of double feeding. Only the top sheet of paper is fed

by the paper feed roller.

As paper is fed to the timing roller by the paper feed roll, the paper is

detected by the paper pass sensor located just ahead of the timing

roller. After the paper is detected, the paper feed clutch turns off and

the paper feed roller and paper feed transfer roller stop rotating. At

this point the paper touches the timing roller and remains. The paper

pass sensor checks the paper feed from the cassette; if paper is not

detected the printer stops and a paper jam error displays.

Detecting the paper

Paper in the casette is detected by the paper detect sensor. When

the paper is detected the sensor turns off. If paper is not detected

the sensor remains off.

Detecting paper level

The amount of paper remaining in tray 1 is detected by the paper

detect sensor. When there is enough paper in tray 1 the sensor

remains off. When the level is low, less than 50 sheets, the sensor

turns on and Load Paper tray 1 displays.