Checklist for Liebert XDP Startup

17

If there is no “Loss of Flow” alarm present—This suggests that there is flow. Test the

pressure differential by closing the ball valve on either the suction line or discharge line to

stop the flow.

This should prompt an alarm for “loss of flow on P1.” This alarm confirms that the switch has

opened on low pressure (below 6 psi; 41kPa; 0.41 bars).

If there is a “Loss of Flow” alarm present—This suggests that there is no flow. Verify

that this is correctly annunciated by looking at the sight glass in the receiver. If a true no-flow

condition exists, the level will not move.

However, if there is flow, but the differential reading is faulty, the level will slowly

drop, indicating flow, while the loss of flow alarm is annunciated.

Check the pressure differential physically by making sure that the electrical connections are

properly connected. Then check the pressure differential electrically by making sure that the

unit has 24VAC across it.

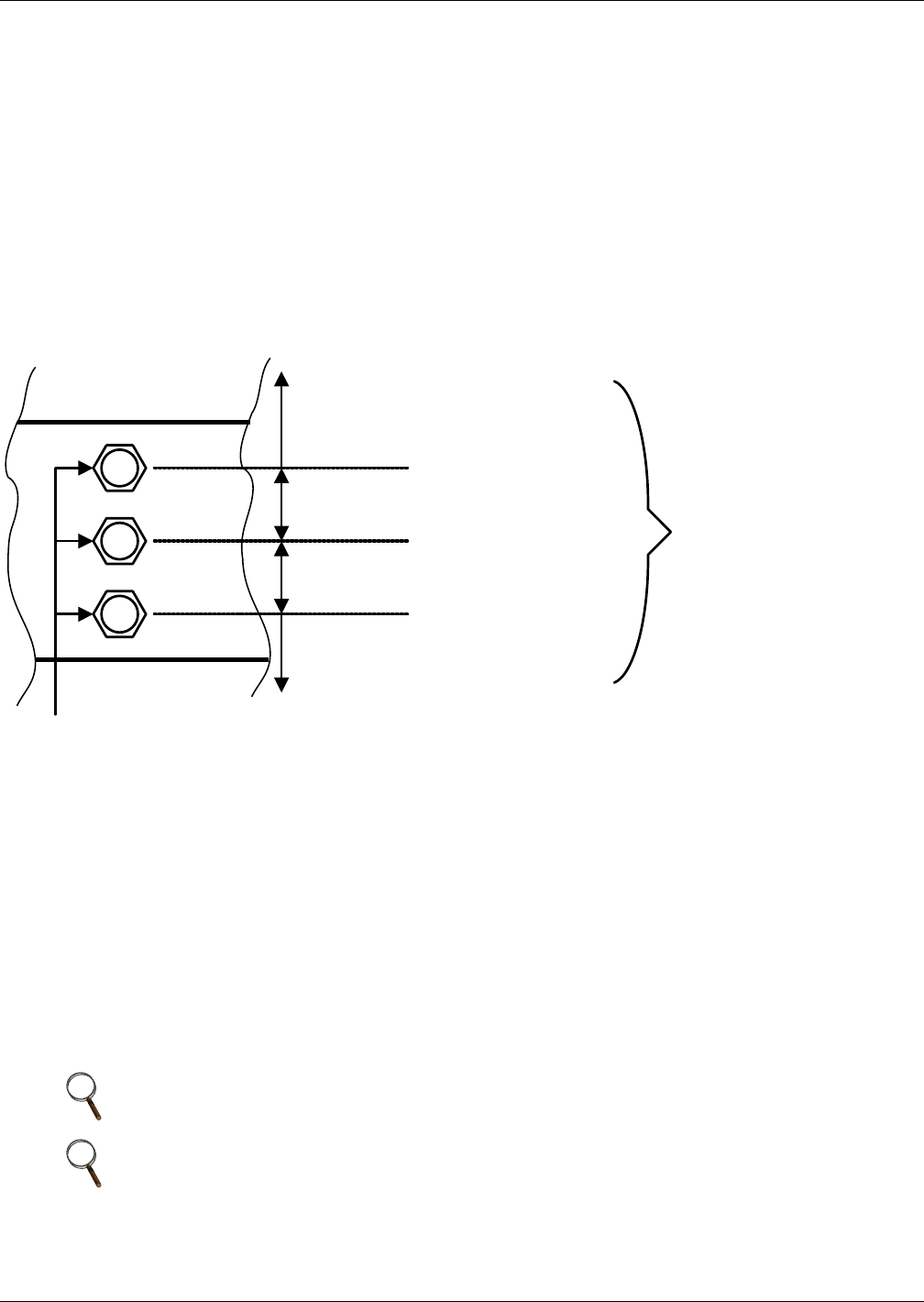

Figure 21 System R-134a liquid level

3.1 Filling the Pumped Circuit—R-134a

1. Connect a charging manifold to the service port of the receiver outlet valve.

2. Purge the hoses.

3. Calculate the amount of R-134a refrigerant needed to charge the system, using the values in

Tables 6, 7, 8 and 9; for assistance, refer to 3.1.1 - Calculating Refrigerant Charge—

Example. The section includes a worksheet to calculate system refrigerant charge requirements.

4. Weigh in the calculated charge.

5. After adding the calculated charge, allow the system to sit 15 to 30 minutes to reach equilibrium.

Observe the refrigerant level through the sight glasses of the receiver. The level should be above

the second sight glass at a minimum when the Liebert XDP is off.

6. If the refrigerant level is improper, the charge must be adjusted.

If the level is too high or too low, recalculate the required charge and reduce or increase the

amount as needed to reach the proper level.

NOTE

All lengths in Tables 7, 8 and 9 are actual pipe lengths, not equivalent pipe lengths.

NOTE

System refrigerant volume calculations derived from Tables 6, 7, 8 and 9 are based on a fully

loaded system. Additional charge may be required for lightly loaded systems.

Operation above sight glass #3 can

make the system operate erratically

and reduce cooling capacity - Reduce

charge to recommended level.

Recommended operating level

Acceptable operating level

Operation below sight glass #1 may

cause loss of flow or cooling. Add

charge to reach recommended level.

For lightly loaded systems,

the recommended operating

level is sight glass #2.

Sight Glasses 1, 2 & 3