2 MAINTENANCE

LOCK-OUT & TAG-OUT INSTRUCTIONS

06-0045

460

VOLTS

DANGER

ELECTRICAL: The panel box contains high voltage

components. Only authorized service personnel

should be allowed inside the box. Authorized service

personnel should be allowed inside the box only

after the baler has been locked-out and tagged-out.

FOREWORD: Before entering any part of the baler, be

sure that all sources of energy have been shut off, all

potential hazards have been eliminated, and the baler

is locked-out and tagged-out in accordance with

O S H A and ANSI requirements. Before servicing the

hydraulic system or the inside of the bale chamber,

THE PLATEN MUST BE PROPERLY SUPPORTED A S

SHOWN ON THE NEXT PA G E.

The specific lock-out and

tag-out instructions may vary from company to company (i.e.

multiple locks may be required, or other machinery may need to

be locked-out and tagged-out). The following instructions are

provided as minimum guidelines.

HYDRAULIC: Stored hydraulic energy must be removed from the baler hydraulic

circuit for complete lock-out and tag-out. Make sure that this energy has been relieved

by manually depressing the solenoid valve pin located in the center of the coil end of

each valve. See Diagrams on pages 2-4 and 2-11.

2-1

INSTRUCTIONS

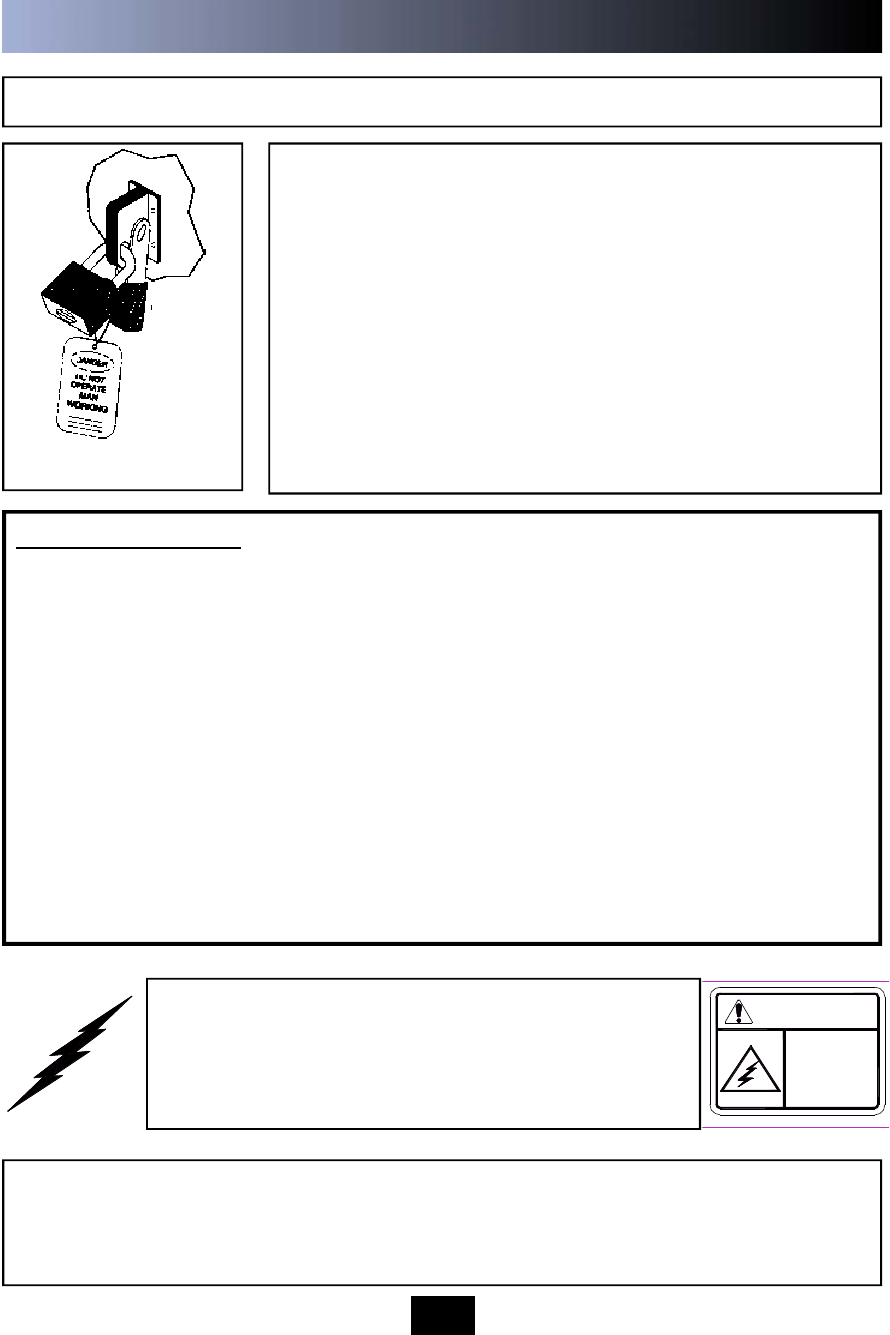

1. Move the main disconnect lever to the OFF position.

2. Padlock the disconnect lever with a keyed padlock and take the

key with you.

3. Along with the padlock, place an appropriate, highly visible,

warning tag on the disconnect lever.

The tag should provide a warning such

as: “ Danger: Do not operate equipment. Person working on equipment. Warning: Do

not energize without the permission of _________________________.”

4. After locking and tagging the baler, try to start and operate the

baler (as outlined in the Operating Instructions) to make sure the

lock-out and tag-out is effective. If the lock-out and tag-out is

effective, remove the key from the keyswitch and take with you.

(Typical disconnect shown, other

types may lock-out differently.)

OFF

400