If switch trip point needs to be adjusted, see page 4.

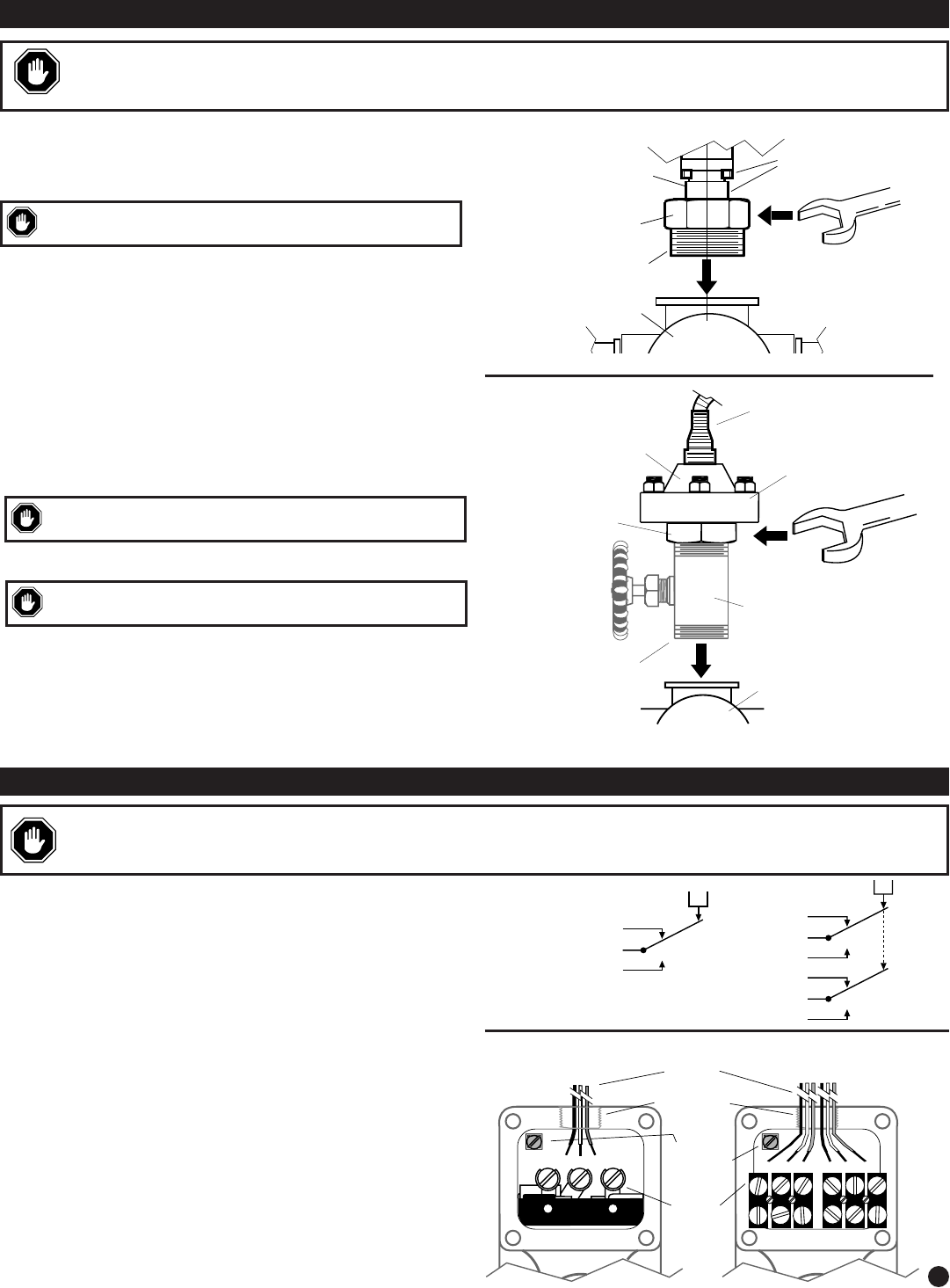

LLS Series Hook-up (all models)

To wire the LLS Series, use proper the electrical conduit.

1. A 3/4''-14 NPT inlet connection for conduit installation is provided

at the top end of the switch enclosure (see opposite page–

“Dimensions” for location).

NOTE: The plastic plug (supplied) is to protect the conduit inlet threads

and must be removed before wiring the unit.

2. Using a 3/16 in. hex wrench, unscrew the 4 hex-cap screws.

Now proceed to remove the square cover to reveal snap-switch(es).

3. To wire the unit, refer to the typical wiring drawing (Figure 3) and

to the Schematic (shown at right). Wire the LLS Series switch(es)

with 60°/75°C (140°/167°F) insulated wire.

4. A terminal (inside the switch enclosure) is provided for case or

equipment grounding, refer to Figure 3 for location.

5. After completing wiring, replace the switch cover and make sure it

is tightly secured before applying power to the system.

3

WIRING THE LLS SERIES PRESSURE SWITCH

Provision for

Case Ground

N.O. N.C. COM.

Terminal

Block(s)

Customer

Wiring

NC NO C NC NO C

3/4 in.-14 NPT

Conduit Inlet

WARNING: PERFORM THE WIRING OPERATION WITH THE POWER SOURCE “OFF”. MAKE SURE VOLTAGE AND CURRENT REQUIRE-

MENTS ARE WITHIN THE LLS RATINGS. BEFORE WIRING THE UNIT DETERMINE VOLTAGE AND POLARITY FOR THE APPLICATION.

IF THE UNIT IS USED IN HAZARDOUS AREAS, MAKE THE AREA SAFE BEFORE REMOVING THE SNAP-SWITCH(ES) COVER.

Figure 3

SPDT

DPDT

NC

C

NO

P

NC

C

NO

P

NC

C

NO

Schematic

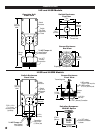

INSTALLING THE LLS SERIES PRESSURE SWITCH

Connecting the LLS and LLSB Series

To install the LLS and LLSB Series,

a vertical mounting is recommended.

1. The unit threads directly into a 2 in. 11-1/2 NPT tee on the lead line.

2. Tighten the bottom housing to the lead line tee using ONLY the

transmitter wrench flats (see figure 1).

3. Check for leakage on any of the connections. Make sure that the

installation conforms with local and other applicable codes.

Connecting the LLSR and LLSRB Series

For mounting the switch enclosure refer to “Dimensions” on page 2.

The following instructions are based on the usage of a PD8187 Pulsation

Dampener option shown in Figure 2 (at right.)

1. Install sensor/pulsation dampener into pressure source connection.

2. Loosen the eight housing bolts until the bottom housing is free to turn.

3. Tighten the bottom housing to the pulsation dampener connection.

4. Tighten the eight housing bolts to 25±3 foot lbs. Stagger the tighten-

ing to assure even clamping.

5. Route capillary away from heat source (exhaust manifold). Excess

capillary should be carefully coiled and secured (do NOT cut it).

2 in. NPT

Use Wrech Flats to

Screw the LLS

Into the Process

Do NOT Tamper with

This Connection

Do NOT Tamper with

these Sealed Connections

Lead line tee

Wrench Flats

WARNING: PERFORM THE INSTALLATION WITH POWER SOURCE “OFF”. NEVER EXCEED RATED PRESSURE RANGE FOR THE UNIT.

USE WRENCH ON SHANK TO TIGHTEN/LOOSEN CONNECTIONS. DO NOT TWIST THE ENCLOSURE WHEN SCREWING THE LLS INTO THE

PROCESS – THIS WILL DAMAGE INTERNAL COMPONENTS, FILLED MECHANISM AND THE SEALS. DO NOT OVERTIGHTEN THE UNIT.

CAUTION: THE PD8187 PULSATION DAMPENER IS NOT INTENDED

AS A SHUTOFF VALVE. APPLY PIPE SEALANT TO THE THREADS.

CAUTION: DO NOT TAMPER WITH OR BREAK SEALED CONNEC-

TIONS. APPLY PIPE SEALANT TO PROCESS CONNECTION THREADS.

CAUTION: WHEN LOOSING THE EIGHT HOUSING BOLTS, MAKE

SURE NOT TO UNSCREW THE GREEN DIAPHRAGM CAPSULE.

Transmitting Tubing

(capillary)

Housing

Bolts

Diaphragm

Body

Pulsation

Dampener

(optional)

Wrench

Flats

Lead Line Tee

1 in. NPT

Figure 1

Figure 2

SPDT DPDT