MDTM-8907N page 3 of 4

3. When connecting the thermocouple extension wire to your thermo-

couple leads, twist the wire connections, then install wire nuts,

such as ceramic type, which have no metal insert.

DO NOT SOLDER.

To prevent problems of interference from electrical noise, DO NOT

route thermocouple wires in the same conduit or within 12 inches

(304 mm) of ignition wires or alternating current conductors.

Metallic-overbraided, thermocouple wire is recommended. It pro-

vides electrical shielding as well as protection against wear and

abrasion.

B. Connecting Thermocouple Wires (ungrounded thermocouple)

1. Remove factory installed jumpers or shunts from TC1 and TC2

terminals before connecting thermocouple(s).

2. Connect the thermocouple leads to the thermocouples. Observe

lead polarity. See Table 1 for thermocouple extension lead color

code and thermocouple polarity.

NOTE: Before continuing to the next step, decide which thermocouple

is to be identified as TC1 and which is to be identified as TC2.

A wire marker should be installed on each end of the thermocou-

ple lead to identify TC1 and TC2.

3. Connect the positive lead of thermocouple TC1 to the positive (+)

terminal of terminal strip TC1.

4. Connect the negative lead of thermocouple TC1 to the negative (-)

terminal of terminal strip TC1.

5. Connect the positive lead of thermocouple TC2 to the positive (+)

terminal of terminal strip TC2.

6. Connect the negative lead of thermocouple TC2 to the negative (-)

terminal of terminal strip TC2.

C. Connecting Output Wires

Wire the SWICHGAGE

®

trip point outputs as shown in the typical

wiring diagrams on the back of this page.

D. Connecting Power Wires

1. Determine the voltage and the polarity of the input power before

attempting to connect the power leads to the MDTM89.

2. On CD ignitions, connect the shutdown lead to the MDTM89

ignition input as shown in the diagrams below.

Operation Test

NOTE: Perform the Operation Test after the MDTM89 is installed and wired

appropriately.

1. a. Rotate the trip point potentiometers TC1 and TC2 clockwise until an

audible click is heard or detente is felt. These are 12-turn

potentiometers.

b. Start the engine or power up the monitor.

2. a. Set the display selector switch to the TC1 position to display the TC1

temperature.

b. Next depress and hold the “Push to Read” trip point push button to

display the TP1 setting.

c. Rotate the TC1 trip point potentiometer counterclockwise until the

display reading is equal to the temperature reading observed in

step 2. a.

d. Trip point TP1 will turn on and trip the shutdown device or alarm;

verify by observation.

e. Rotate the trip point potentiometer TC1 clockwise several turns to

turn off TP1.

f. Reset alarm or shutdown device.

3. a. Set the display selector switch to the TC2 position to display the TC2

temperature.

b. Next, depress and hold the “Push to Read” trip point push button to

display the TP2 setting.

c. Rotate the TC2 trip point potentiometer counterclockwise until the

display reading is equal to the temperature reading observed in

step 3.-a.

d. Trip point TP2 will turn on and trip the shutdown device or alarm;

verify by observation.

e. Rotate trip point potentiometer TC2 clockwise several turns to turn

off TP2.

f. Reset alarm or shutdown device.

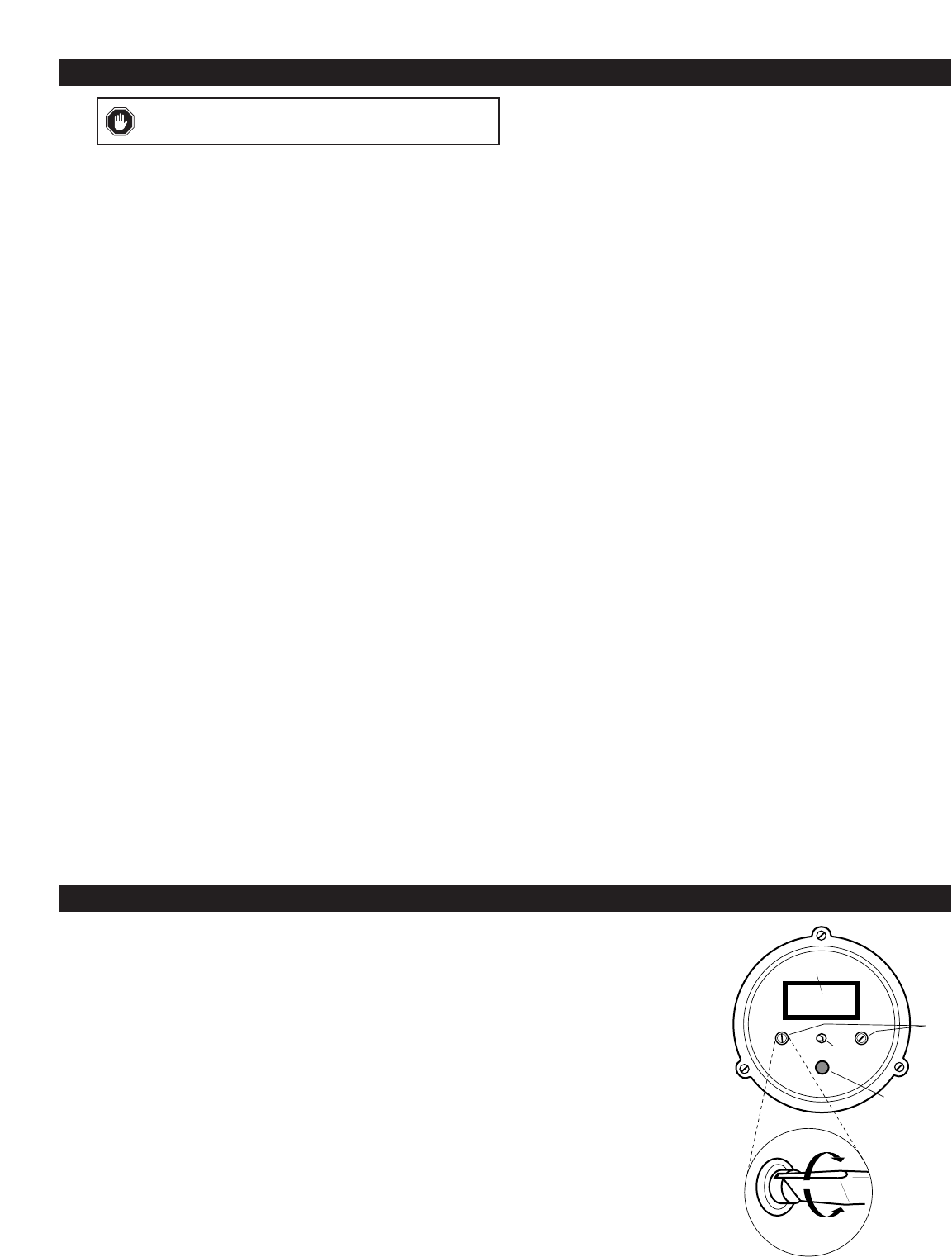

A

C

D

12 turn

potentiometers

DETAIL

B

Face Plate Diagram

A

. Trip point/display

toggle switch.

B

. Readout digital

display.

C

. Trip point

potentiometers.

D

. Push to read trip

point button.

WIRING AND ADJUSTMENT INFORMATION

TRIP POINT ADJUSTMENT INFORMATION

Trip Point Adjustments

1. Power up the temperature monitor by turning on power or by

starting engine.

2. Set the display selector switch to the TC1 position.

3. Depress the “Push to Read” trip point push button to read trip point.

4. Rotate the trip point potentiometer TC1 until the display indicates

the desired trip point temperature for TC1.

5. Set the display selector switch to TC2 position.

6. Depress the “Push to Read” trip point push button to read the

trip point.

7. Rotate the trip point potentiometer TC2 until the display indicates

the desired trip point temperature for TC2.

CAUTION:

The use of non thermocouple wire will cause

inaccurate temperature sensing and erratic operation.