3

MATERIALS OF CONSTRUCTION

BODY / COVER: Aluminium with Teflon Imprenated Hard Anodized (PolyLube) Surfaces

PROBES: 316 Stainless Steel

SEALS - COVER, PROBES: Buna N

RATINGS / SPECIFICATIONS

TEMPERATURE: 10 F to 180 F

CONDUIT CONNECTION: 1/2” NPT

ELECTRICAL RATING: 10 amp. 250VAC maximum; 1/2 amp. 125VDC; 1/4 amp. 250VDC; 5 amp.

125VAC lamp load. Note: each pole must be the same polarity to utilize these ratings.

MICROSWITCHES: Mechanical S.P.D.T. (Single Pole Double Throw)

INTERNAL WIRING CONNECTIONS: Screw Clamp

NEMA STANDARDS: NEMA 1 (General Purpose); NEMA 4 (Watertight & Dusttight); NEMA 7 (Haz-

ardous Locations, Class I Groups B, C, & D); NEMA 9 (Hazardous Locations, Class II, Groups E, F, &

G); NEMA 12 (Oiltight and Driptight); and NEMA 13 (Oiltight and Dusttight).

UL LISTINGS: Industrial Control Equipment for use in Hazardous Locations, Class I, Groups B,C, & D

and Class II, Groups E, F, & G

MAINTENANCE

The BVLS normally requires no maintenance. However, in certain situations the switch adjustment

screws may require some attention to either advance or retard the cam actuated switch point. This

enables precise adjustment of the switch timing throughout the life of the unit.

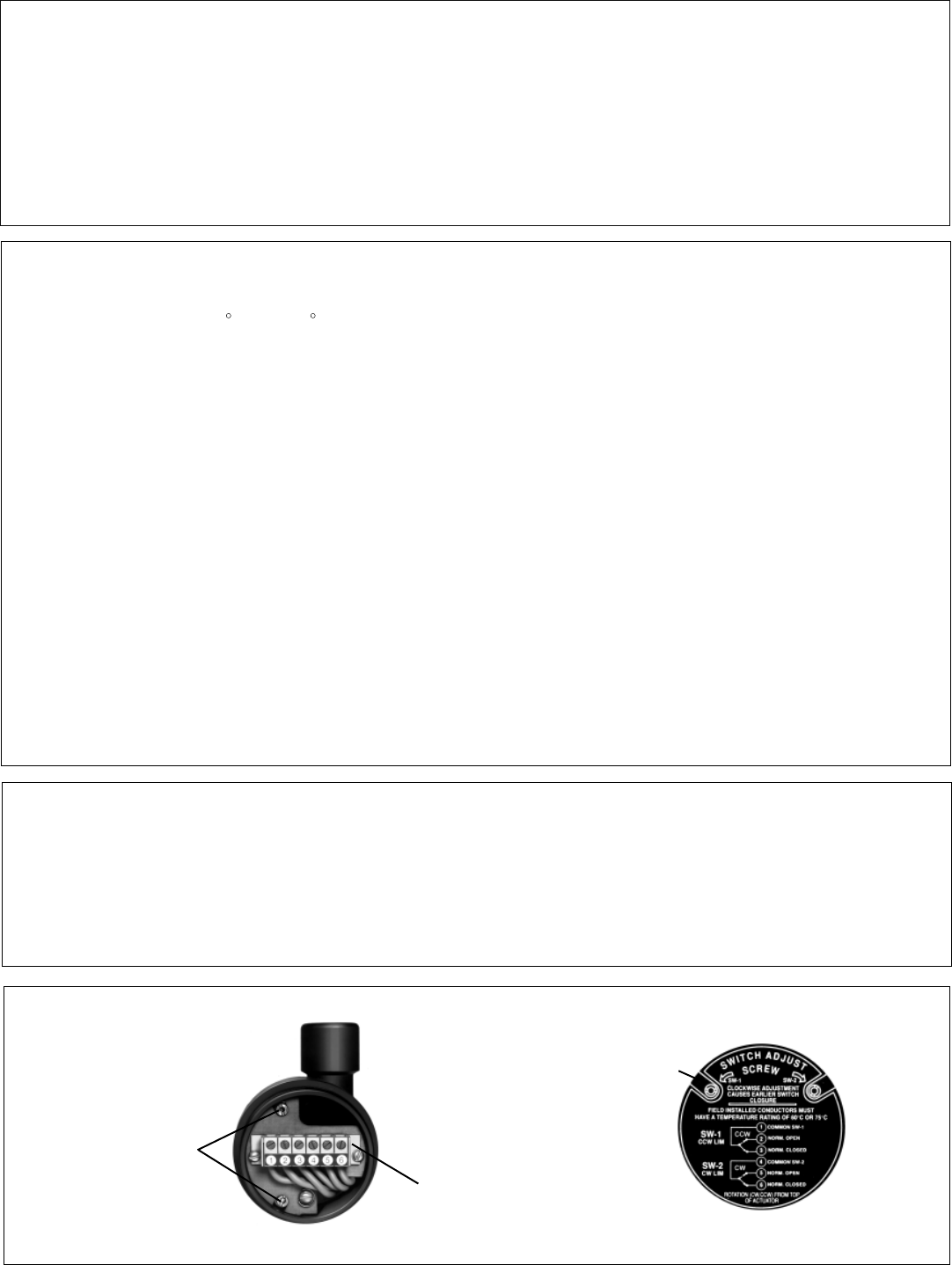

Switch Adjustment

Screws

Terminal Strip

Electrical Schematic as

Shown - Inside Cover