4 Photomicrosensor (Transmissive) EE-SX1107

Precautions

■ Soldering Information

Reflow soldering

• The following soldering paste is recommended:

Melting temperature: 216 to 220°C

Composition: Sn 3.5 Ag 0.75 Cu

• The recommended thickness of the metal mask for screen printing is between 0.2 and 0.25 mm.

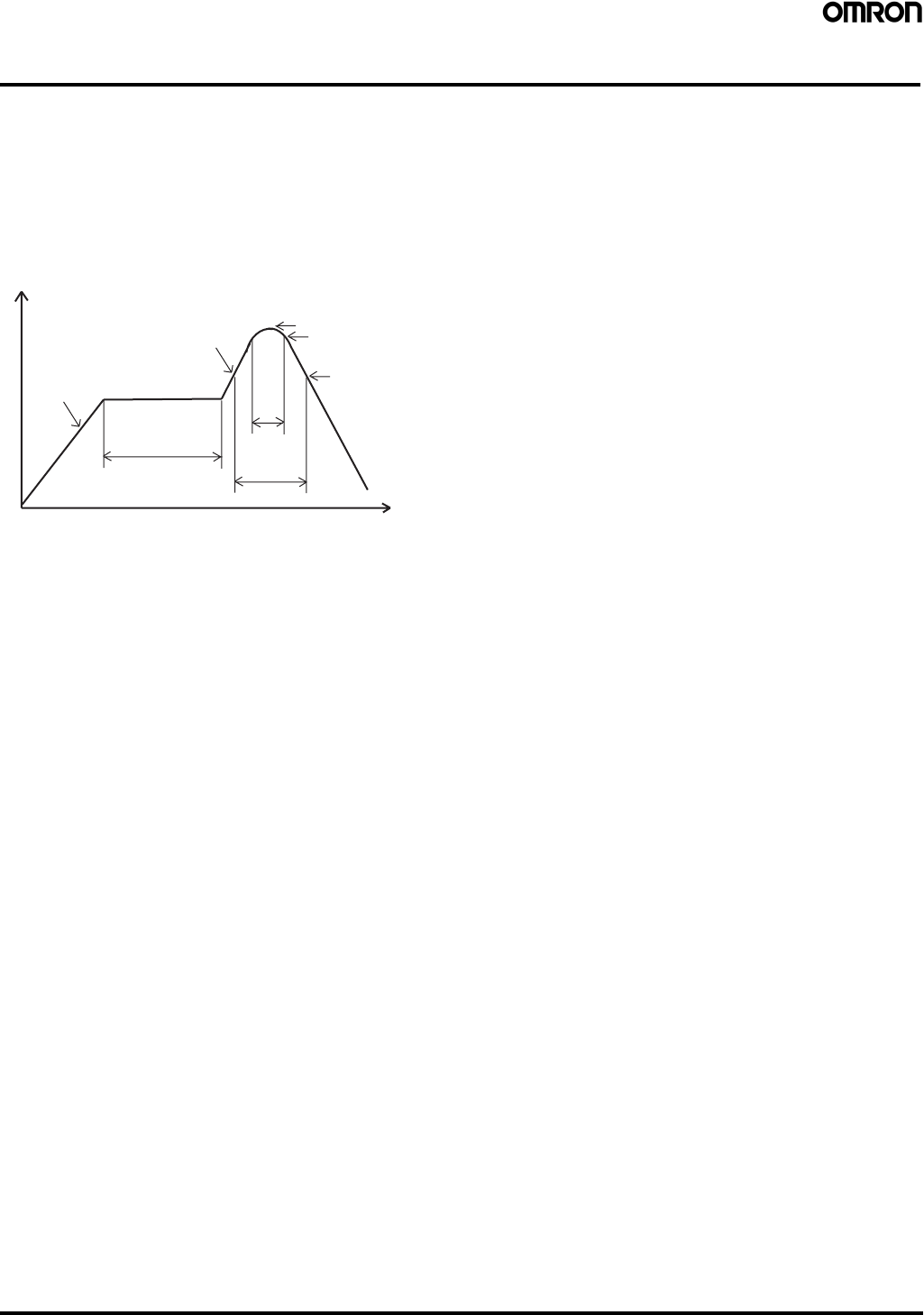

• Set the reflow oven so that the temperature profile shown in the following chart is obtained for the upper surface of the product being soldered.

Manual soldering

• Use “Sn 60” (60% tin and 40% lead) or solder with silver content.

• Use a soldering iron of less than 25 W, and keep the temperature of the iron tip at 350°C or below.

• Solder each point for a maximum of three seconds.

• After soldering, allow the product to return to room temperature before handling it.

Storage

To protect the product from the effects of humidity until the package is opened, dry-box storage is recommended. If this is not possible, store the

product under the following conditions:

Temperature: 10 to 30°C

Humidity: 60% max.

The product is packed in a humidity-proof envelope. Reflow soldering must be done within 48 hours after opening the envelope, during which time

the product must be stored under 30°C at 80% maximum humidity.

If it is necessary to store the product after opening the envelope, use dry-box storage or reseal the envelope.

Baking

If a product has remained packed in a humidity-proof envelope for six months or more, or if more than 48 hours have lapsed since the envelope

was opened, bake the product under the following conditions before use:

Reel: 60°C for 24 hours or more

Bulk: 80°C for 4 hours or more

260°C max.

Time

120 sec

Temperature

1 to 5°C/s

150 to 180°C

40 sec max.

10 sec max.

1 to 5°C/s

255°C max.

230°C max.