4 5

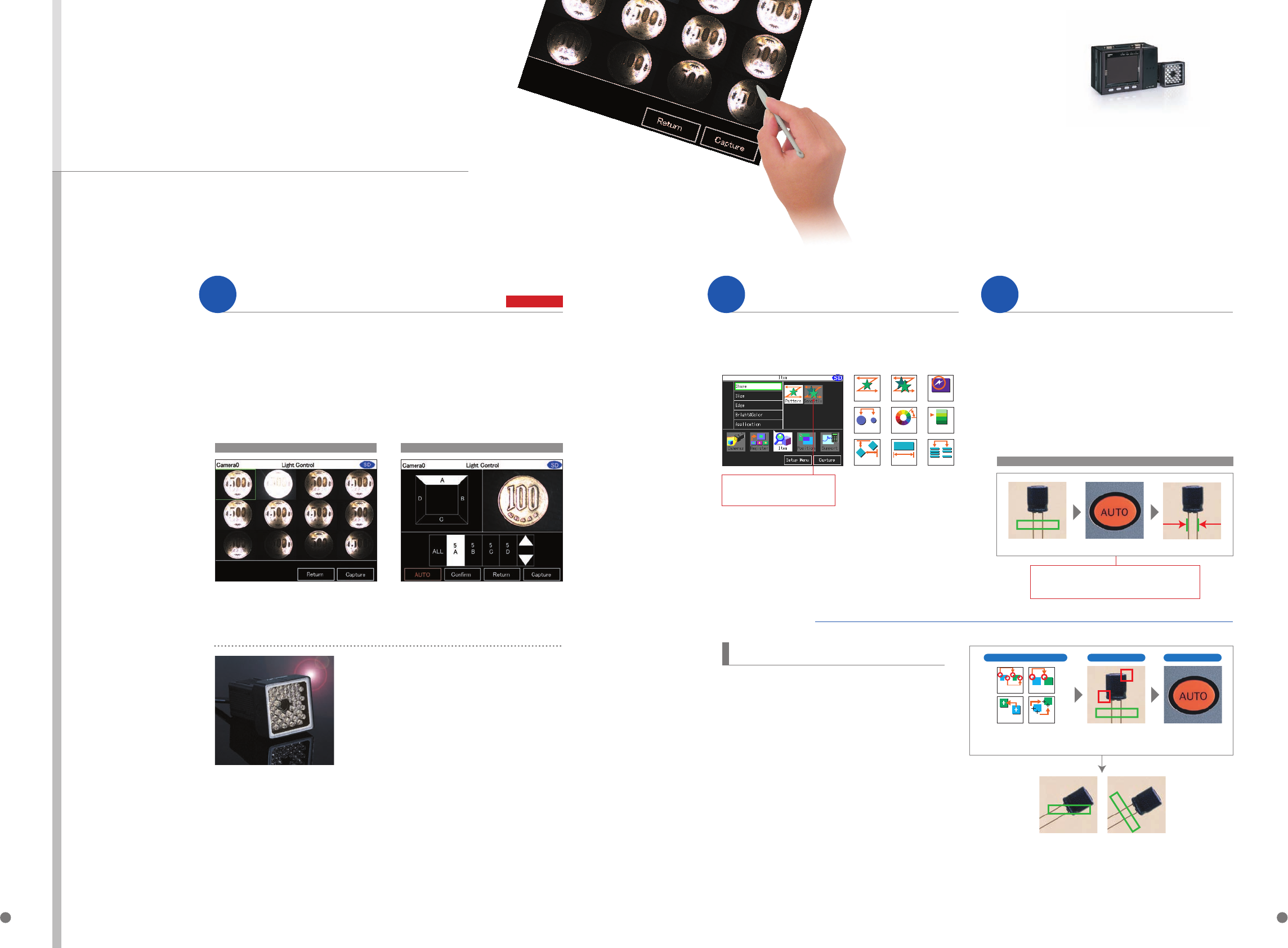

Smart Recipe is on Omron's invention of 3-step setting procedure.

By adopting a new algorithm to encapsulate “human know-how”, the auto setup

for lighting and measurement now possible.

Anyone can rapidly perform a high level of image processing.

Smart Recipe

The Built-in lighting camera and improved controller brings

about an even higher degree of automatic lighting. With this

camera you can produce up to a maximum of 1296 patterns of

reflective lighting making the chore of choosing lighting

equipment unnecessary. The lighting setup can be managed as

digital data so it is possible to store the optimal setup for each

job, and it smoothly handles the changing of settings. It is also

possible to fine-tune the customized setup can be added.

Built-in lighting camera that enables an advanced automatic lighting

Patent pending

Width measurement

Automatic lighting setup Customized lighting setup

Easily adjusts position

Basic operations merely through

selection of on-screen icons

Intuitive operations

Appropriate filters and edge scan directions

for width measurement can be automatically

set by analyzing the target image.

Select the suitable position

correction icon for

different tests

Indicate each region

(red frame) of the

position correction.

Press Auto key.

Obtain the width

Indicate the region Press the Auto key

Step 1 Step 2 Step 3

With automatic lighting setup, user can simply select

the best image from thumbnail of candidate images.

A more detailed set up is possible with the

customized lighting setup while looking at the image.

Pattern

Sensiti

Area

Hue

Position Width Count

2 model

1 model

Position

Area

Defect

Bright

No position correction

Position corrected

In response to the position

difference,

the measurement region is

automatically adjusted.

Smart sensor

ZFX

-

C

Step1 Step2 Step3

Choose best lighting

The know-how and trial and error that have been indispensable and required much time

and effort up to now in lighting setup is now an automated process. By just selecting the

best one from the candidate images automatically captured by changing the lighting

pattern with the auto-lighting, anyone can easily find the optimal lighting. User can now

easily determine settings for shiny work with high degrees of reflection and black

monochrome work with low degrees of reflection, something very tricky before. In

addition, when a more detailed setup is needed, the customized setup can be used to

incorporate know-how.

Choose measurement icon

The measurement method can be specified by just choosing

the icon from out of a total of 9 measurement items for

different types of inspection.

3-step position correction

Even when the position of work changes due to the

conveyer condition, the excellent position correction

function can come into play allowing adjustment using

the work contours, two stage position correction and so

on. With the auto setup, position difference can be easily

adjusted to enable stable measurement.

Draw region, press and go

Just specify the region of interest and press Auto key and

the system will determine the most suitable parameters for

the target image.

Now anyone can easily perform a complex and advanced

parameter setting which used to require special knowledge

and cumbersome steps.

Customized setting is also possible by fine tuning the

parameters automatically set up. The time required to set up

parameters can be significantly reduced.