12

DC

• Use crimped and sealed copper ring terminal lugs with 5/16” (.79 cm) hole or compression-type lug

to connect battery cables to DC terminals. Soldered cable lugs are also acceptable.

• Use recommended cable sizes (see page 51) to reduce losses and ensure high performance of FX

(smaller cables can reduce performance and possibly damage the unit).

• Keep cables together (e.g., using a tie-wrap) as much as possible.

• Ensure cables pass through the same knockout and conduit ttings to allow inductive currents to

cancel.

TORQUE REQUIREMENTS

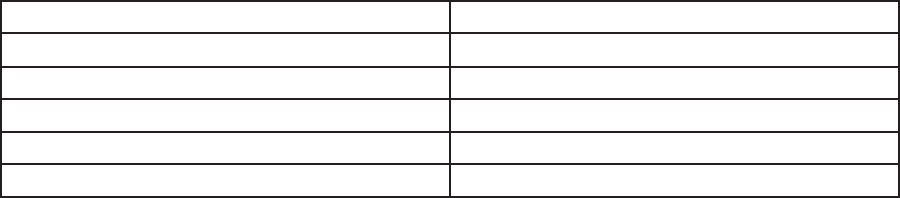

CONNECTION TORQUE IN POUNDS/Nm

AC and PV breakers to 22 inch-lbs/2.48 Nm

DC shunt to 15 foot-lbs/20.4 Nm

DC battery connections to 10 foot-lbs/13.6 Nm

FX’s DC terminals to 5 foot-lbs/3.38 Nm

FX’s AC terminals to 30 inch-lbs/3.38 Nm

Table 1 Torque Values for Installation