Aluminum Electrolytic Capacitor

Design, Specifications are subject to change without notice. Ask factory for technical specifications before purchase and/or use.

Whenever a doubt about safety arises from this product, please inform us immediately for technical consulation without fail.

– EE16 –

Application Guidelines

1. Circuit Design

Ensure that operational and mounting conditions

follw the specified conditions detailed in the catalog

and specification sheets.

1.1 Operating Temperature and Frequency

Electrolytic capacitor electrical parameters are

normally specified at 20°C temperature and 120Hz

frequency. These parameters vary with changes in

temperature and frequency. Circuit designers

should take these changes into consideration.

(1) Effects of operating temperature on electrical

parameters

a)At higher temperatures,leakage current and

capacitance increase while equivalent series

resistance(ESR) decreases.

b)At lower temperatures, leakage current and

capacitance decrease while equivalent series

resistance(ESR) increases.

(2) Effects of frequency on electrical parameters

a)At higher frequencies, capacitance and

impedance decrease while tan δ increases.

b)At lower frequencies, ripple current generated

heat will rise due to an increase in equivalent

series resistance (ESR).

1.2 Operating Temperature and Life Expectancy

(1) Expected life is affected by operating temperature.

Generally, each 10°C reduction in temperature

will double the expected life. Use capacitors at

the lowest possible temperature below the

maximum guaranteed temperature.

(2) If operating conditions exceed the maximum

guaranteed limit, rapid eIectrical parameter

deterioration will occur, and irreversible damage

will result.

Check for maximum capacitor operating tempera-

tures including ambient temperature, internal

capacitor temperature rise caused by ripple current,

and the effects of radiated heat from power

transistors, IC?s or resistors.

Avoid placing components which could conduct

heat to the capacitor from the back side of the circuit

board.

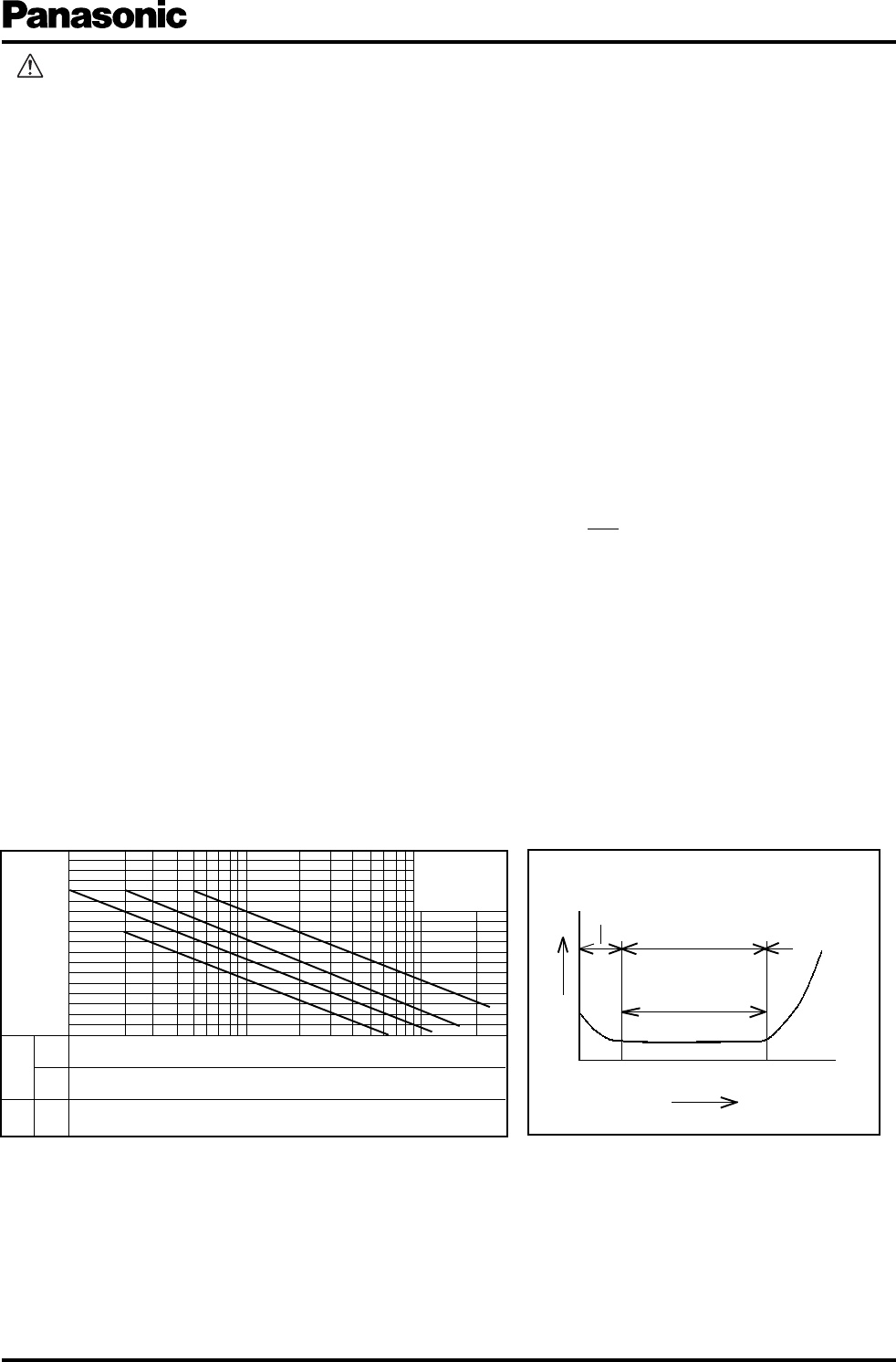

(3)The formula for calculating expected Iife at lower

operating temperatures is as fllows;

L

2 = L1 x 2 where,

L

1: Guaranteed life (h) at temperature, T1° C

L

2: Expected life (h) at temperature,T2°C

T

1: Maximum operating temperature (°C)

T

2: Actual operating temperature, ambient

temperature + temperature rise due to

ripple currentheating(°C)

A quick eference capacitor guide for estimating

exected life is included for your reference.

2000 5000 10,000 20,000 50,000 100,000 200,000

120

110

100

90

80

70

60

50

40

8h/d

1 2 3 4 5 7 20

3

6 10 15 20 30

■ Expected Life Estimate Quick Reference Guide

■ Failure rate curve

1. 85°C2000h

2.105°C1000h

3.105°C2000h

4.105°C5000h

1

2

3

4

Capacitor Ambient Temperature

(h)

Years

Years

24h

operat-

ion

Failure rate

Time

Initial failure period

Life Time

Random failure period

Wear failure period

T1-T2

10

Mar. 2005