121021

2

3

5

6

13

4

2

3

4

5

689

1112

77

7

7

Waterless Plate (PEARLdry™ Plus)

The 3404DI uses PEARLdry™ Plus, a roll-type

waterless plate. This plate uses laser action to

form surfaces that are either adhesive or repellent

to ink. Each plate lasts for approximately 20,000

impressions, and will accommodate both short

runs as well as longer, large-lot production.

Note: The number of available plate impressions depends on

printing conditions such as the type of ink and paper

stock used.

High Printing Quality From an Offset Press

RYOBI has packed the 3404DI’s compact body with a host of

outstanding printing features. Incorporating RYOBI’s unrivaled offset

printing know-how, it features a highly reliable, robust design that

yields high printing quality and promises a long and productive

service life.

Dimensions

Compact Design Based on a Unique

Cylinder Arrangement

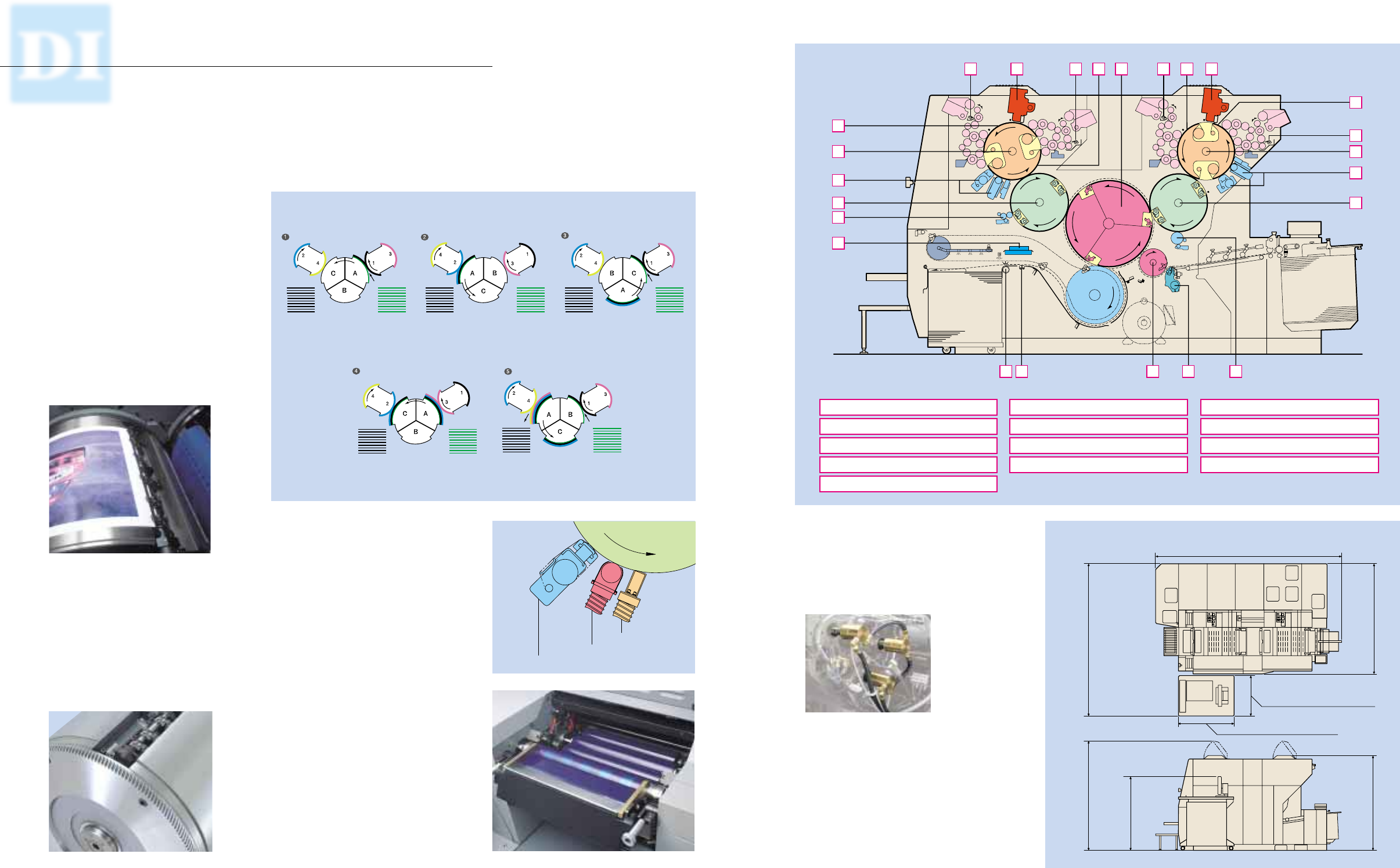

The 3404DI uses a satellite V-shaped 5-cylinder

system consisting of two sets of double-

diameter blanket cylinders and plate cylinders,

which rotate around a triple-diameter impres-

sion cylinder. Paper is tightly held by the

impression cylinder grippers and rotated twice

without a gripper change for precise 4-color

printing. The large diameter of the impression

cylinder reduces paper curling as well as

damage to the printed material. Thanks to this

cylinder arrangement, the RYOBI 3404DI

achieves a compact design that’s about the

same size as a conventional 2-color press.

Inking section

Ink roller temperature

control system

Three Plate Cleaning Devices

Once imaging has been completed, plate

cleaning is carried out by three devices—a dry

cleaning device, a wet cleaning device and a

vacuum, to remove residual silicone on the

plate.

Plate cleaning device (wet cleaning)

Plate cleaning device (dry cleaning)

Vacuum

1. Imaging head

2. Printing plate

3. Plate cylinder

4. Plate cleaning device

5. Blanket cylinder

6. Automatic blanket cleaning device

7. Automatic ink roller cleaning device

8. Underswing system

9. Paper feed drum

Solid, Reliable Design

The 3404DI uses a bearer contact system to

maintain constant plate pressure with each

rotation of the cylinder. Plus, induction-

hardened ultra-high-precision helical gears and

cylinders fitted with ultra-high-precision

bearings ensure consistent, stable printing

quality over long periods of use.

Ultra-high-precision helical gears are used

on the impression cylinder

Plate cleaning devices

Paper Travel

Sheets are fed one-per-rotation of the

plate and blanket cylinders. The paper

is held by the impression cylinder

(surface A). Blanket cylinder 1 prints

the first color.

Blanket cylinder 2 prints

the second color.

The paper printed with the second

color is not transferred to the

delivery section, but enters the

second rotation while being held by

the impression cylinder grippers.

During the second rotation,

blanket cylinder 3 prints the

third color on the sheet.

When blanket cylinder 4 finishes

printing the fourth color, the sheet

is delivered to the delivery pile.

3,230 mm (10'7")

1,915 mm (6'3")

720 mm (2'4")

990 mm (3'3")

2,635 mm (8'8")

1,913 mm (6'3")

1,298 mm (4'3")

1,665 mm (5'6")

Ink Roller Temperature Control System

Roller temperature is maintained at an optimum

level by circulating temperature-controlled water

(warm water and cold water) inside the oscillating

rollers and fountain rollers. By minimizing fluctua-

tions in ink roller temperature, consistent printing

quality is maintained, even during long print runs.

The triple-diameter impression cylinder

reduces paper curl

Mechanical Configuration

10. Impression cylinder

11. Decurling device

12. Suction wheel

13. Infrared dryer (option)

11-Zone Divided Ink Fountains

Ink fountains are divided into 11 zones, each

having its own motor. The ink supply volume

for each zone is remotely controlled from the

operation stand.

Inking Mechanism

Each inking unit consists of 15 rollers including

4 form rollers, ensuring uniform inking.