User-Friendly Operation Thanks to Automation

Simple, Straightforward Centralized

Control from the Operation Stand

All major operations for the RYOBI 3404DI are

initiated and controlled from the operation stand.

Setting the number of printed sheets; job data

entry, interruption and recall; presetting the ink

fountain keys; and cleaning are all centrally

controlled from the operator’s position. A large-

format 14.1-inch LCD ensures user-friendly

operation.

Automatic Ink Fountain Key Presets

Calculating the image area ratio for each color is

done simultaneously with imaging. Presetting the

ink fountain key is done automatically from the

operation stand based on this data. This allows

easy control of the ink fountain key opening

volume, dramatically reducing the time and effort

involved in making color adjustments.

RYOBI Program Inking

RYOBI Program Inking automatically supplies ink

to the ink rollers to match the image from the

very start of printing. After the set number of

prints is finished, the ink on the rollers is auto-

matically restored to an even state, allowing the

operator to proceed quickly to the next job and

minimizing the amount of wasted paper generated

at the start of printing.

The RYOBI 3404DI is loaded with automated processes, from

plate advance and imaging to making color adjustments—

operations that once required high levels of experience and skill.

Its user-friendliness ensures that even operators with little

experience can achieve quality printing in a short period of time.

Convenient

Auto Print Function

The RYOBI 3404DI features a

convenient Auto Print function.

Printing operations start just

by selecting the Auto Print

command on the operation

stand’s monitor screen. Plate

advancing, imaging, printing and

blanket cleaning are all carried

out at a click of a button.

Automatic Cleaning

Devices

The RYOBI 3404DI comes

standard with an automated cleaning system for

both ink rollers and blankets (including an impres-

sion cylinder cleaning function). This reduces the

cleaning time required when switching jobs, thus

lessening the workload for the operator.

RYOBI PDS-E

Printing Density Control System (option)

The RYOBI PDS-E Printing Density Control System

is an option on the 3404DI. Color adjustments

previously based on the experience and intuition of

the operator can now be made using numerical

values from solids densities calculated for each

color. This system allows the operator to easily

match printing output to the OK sheet and keep

quality consistent.

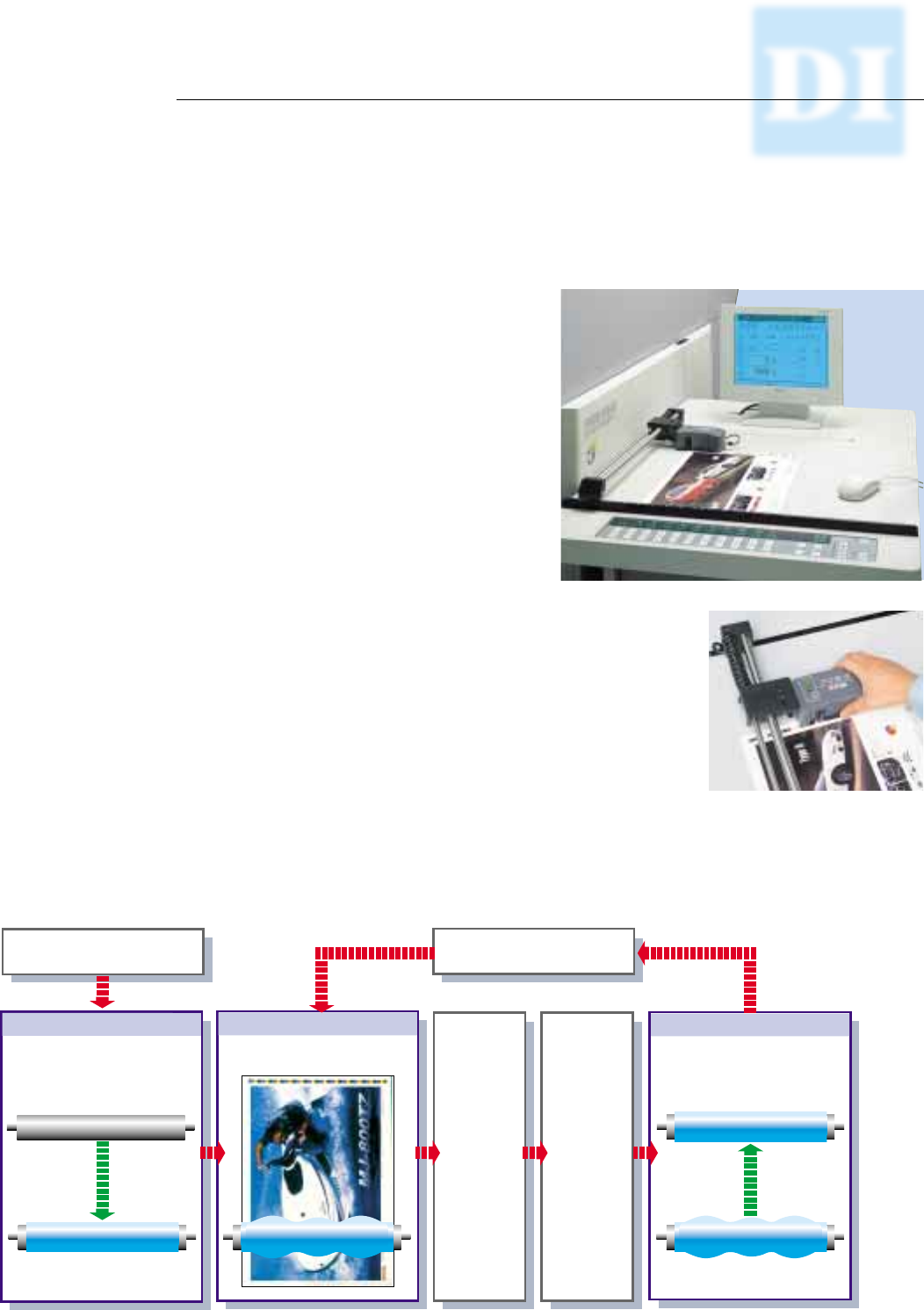

RYOBI Program Inking Flowchart

RYOBI PDS-E printing density

control system (option)

Operation stand

No ink on rollers

Start Inking

Minimum amount of ink

supplied to rollers

Preset Inking

Automatic ink supply

to match image

Printing

starts

automatically

Production

printing

starts

Set no. of prints finished

Smart End Inking

Ink on rollers returned

to even state

Note: Manual ink volume adjustment may become necessary depending on the printing conditions such as ink, stock and print image (especially when printing

a much lighter image job after a heavy solid print job.)