< previous | home | next >

EZ Manual: XL4xxe 4

Barcode SATO International Pte Ltd

Electric Checks and Adjustments

Chart 2

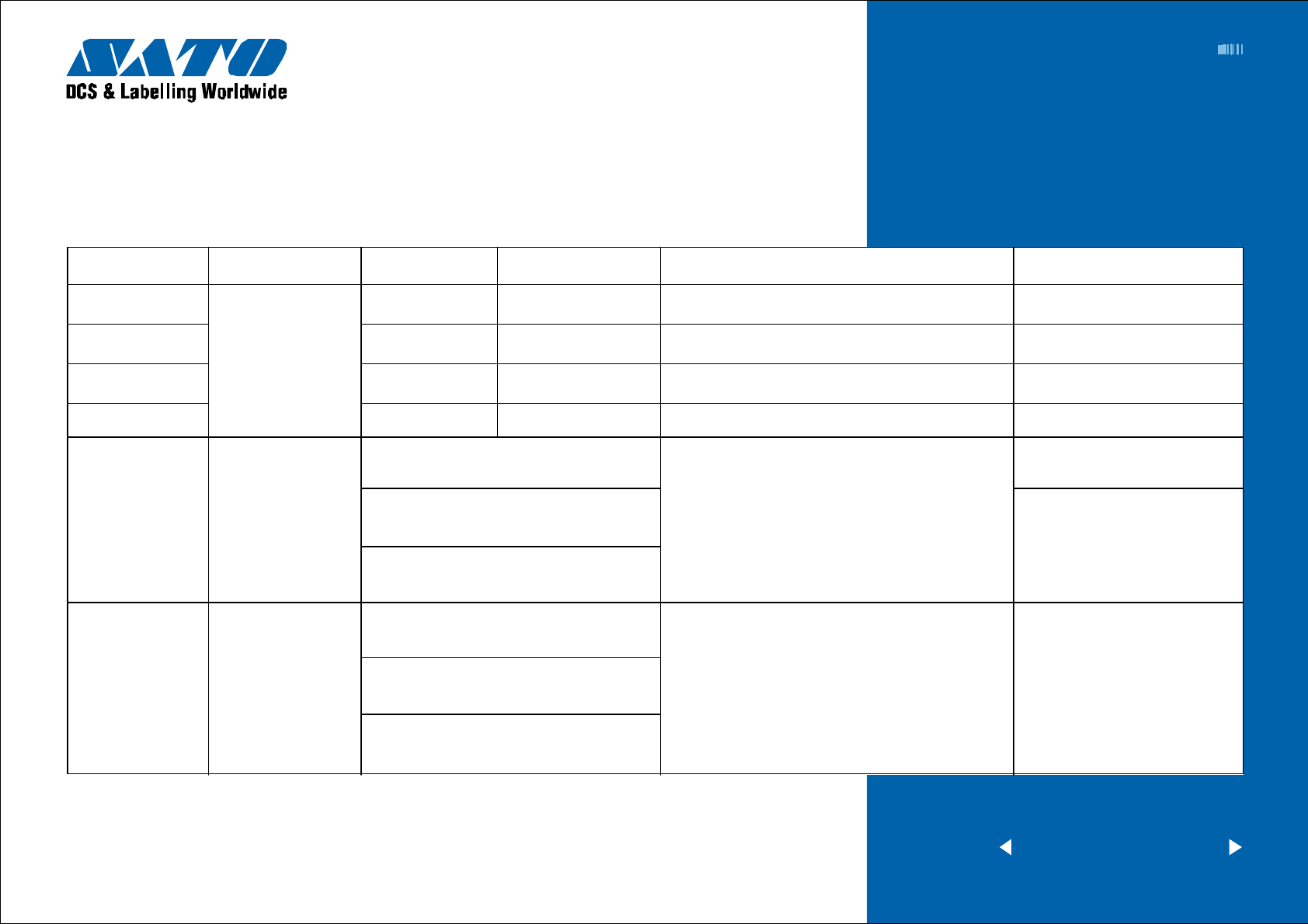

TP TEST POINT CHART

Dial test point Comment Voltage Voltage Range Check pin on TP Test Module and Main PCB Adjustment to VR

0 +5.0 VDC +4.8V to +5.2V CH3A(+5.0V) - CH1A(GND) N/A

1

DC power Supply

+2.0 VDC +1.9V to +2.1V CH4A(+2.0V) - CH1A(GND) N/A

2 +3.3 VDC +3.1V to +3.5V CH5A(+3.3V) - CH1A(GND) N/A

3 +24.0 VDC +23.5V to +24.5V CH6A(+24.0V) - CH1A(GND) N/A

VR8 and VR2

4 I-Mark Sensor Level CH1B(+8.4V) - CH1A(GND)

5 CH2B - CH1A(GND) VR1 and VR9 (Fine adjustment)

Low level (Set the no eye-mark point

in the sensor’s) = Less than +0.5V

High level (Set the eye-mark in the sensor’s)

= Low level plus more than +0.9V

High level (with eye-mark point) - Low level

(without eye-mark point) = +0.9V

Low level (Set the label backing liner or centre

hole tag in the sensor’s)

= Less than +0.5V

High level (Set the label and tag in the

sensor’s) = Low level plus more than +0.1V

High level (printing point) -

Low level (gap point) = +1.0V

(VR2 is used for adjusting the

light reception flow. If there is

difference between the high and

low level, adjust VR2 to allow

some level difference.)

Gap/Tag Center

Hole Sensor Level