26

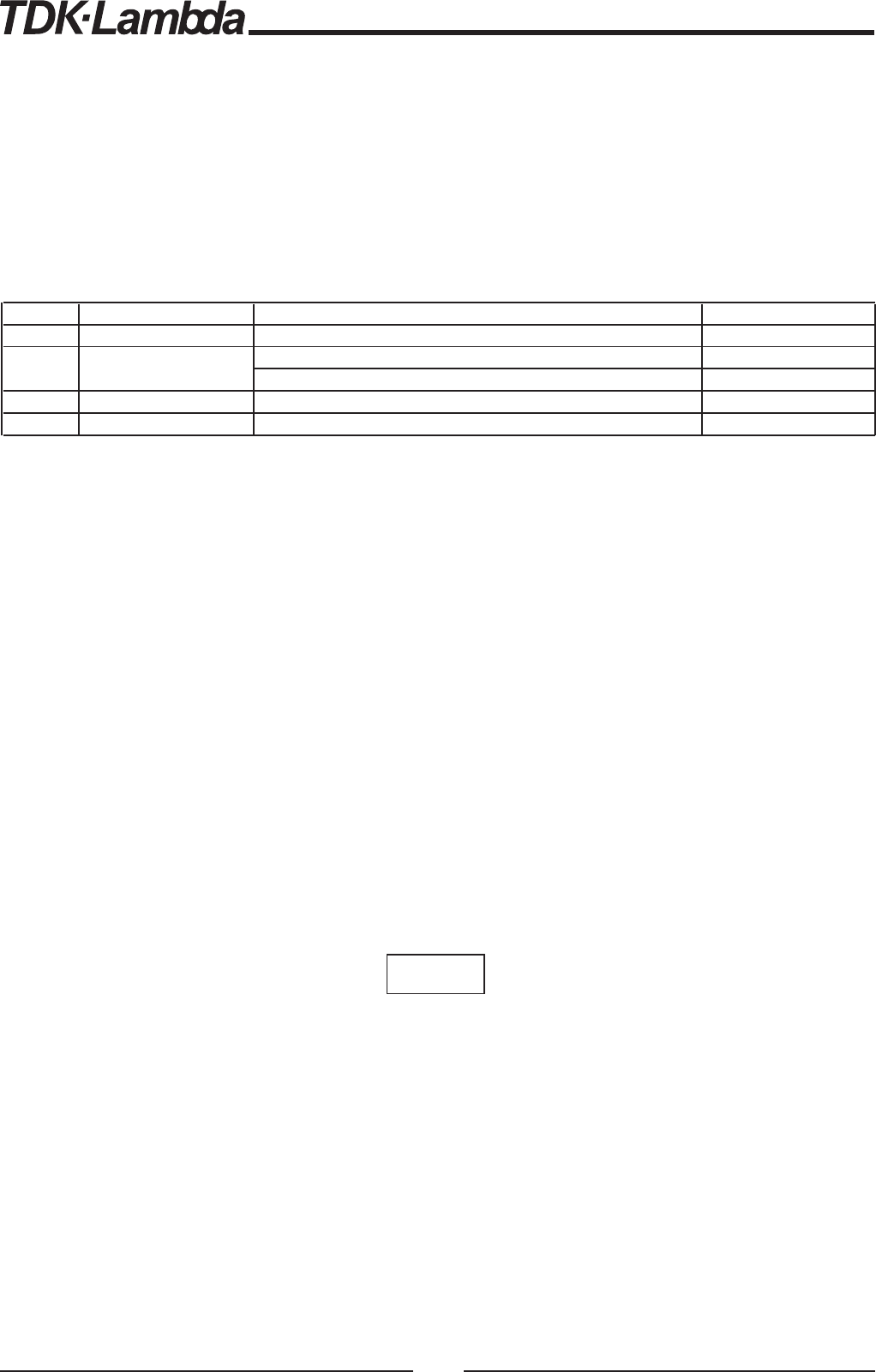

Step no Item Description Reference

1 Inspection Initial physical inspection of the power supply Section 3.3

2 Installation Installing the power supply. Section 10.4

Ensuring adequate ventilation. Section 10.5

3 AC source AC source requirements Section 3.6

4 Load connection Wire size selection. Section 10.7

Table 10-1: Basic setup procedure

CHAPTER 10 FPS-S1U RACK INSTALLATION

10.1 GENERAL

This chapter contains instructions for initial inspection, preparation for use and repackaging for shipment.

In some sections in this chapter, where the instructions for the FPS-S1U and the FPS1000 are identical,

a reference to a section describing the FPS1000 will be given.

10.2 PREPARATION FOR USE

Table 10-1 below describes the basic setup procedure. Follow the instructions in Table 10-1 in the sequence

given to prepare the FPS-S1U rack for use.

10.3 INITIAL INSPECTION

Refer to Sec. 3.3 for details.

10.4 FPS-S1U RACK MOUNTING

The FPS-S1U is designed to be mounted in a 19" rack. Use a support bars or surface to provide adequate

support for the rear of the power supply. Secure the FPS-S1U to its location using the front panel using

M6x12 screws via the mounting holes at its front side (Refer to the outline drawings in Chapter 11).

Do not obstruct the air exhaust at the rear panel of the unit.

10.5 LOCATION MOUNTING AND COOLING

The FPS1000 units installed in the FPS-S1U rack are fan cooled. The air intake is at the front panel and

the exhaust is at the rear panel. Upon installation allow cooling air to reach the front panel and allow

minimum 50mm of unrestricted air space at the rear of the unit for the air exhaust.

10.6 AC SOURCE REQUIREMENTS

Refer to Sect 3.6 for details.

10.7 CONNECTING THE LOAD

WARNING

Turn off the AC input power before making or changing any rear panel connection.

Ensure that all connections are securely tightened before applying power. There is a

potential shock hazard when using a power supply with a rated output greater than 40V.

10.7.1 Load Wiring

.Refer to Sec. 3.7.1, 3.7.2 and 3.7.3 for details.

10.7.2 Inductive loads

To prevent damage to the power supply from inductive kickback, a diode should be connected across the

output. The diode voltage and current rating should be greater than the power supply maximum output

voltage and total current rating. Connect the cathode to the positive output and the anode to the negative

output. Where positive load transients such as back EMF from a motor may occur, connect a surge

suppressor across the output to protect the power supply. The breakdown voltage rating of the suppressor

must be approximately 10% higher than the maximum output voltage of the power supply.