E9-2

9. GENERAL MAINTENANCE

ENGLISH VERSION EO1-33007

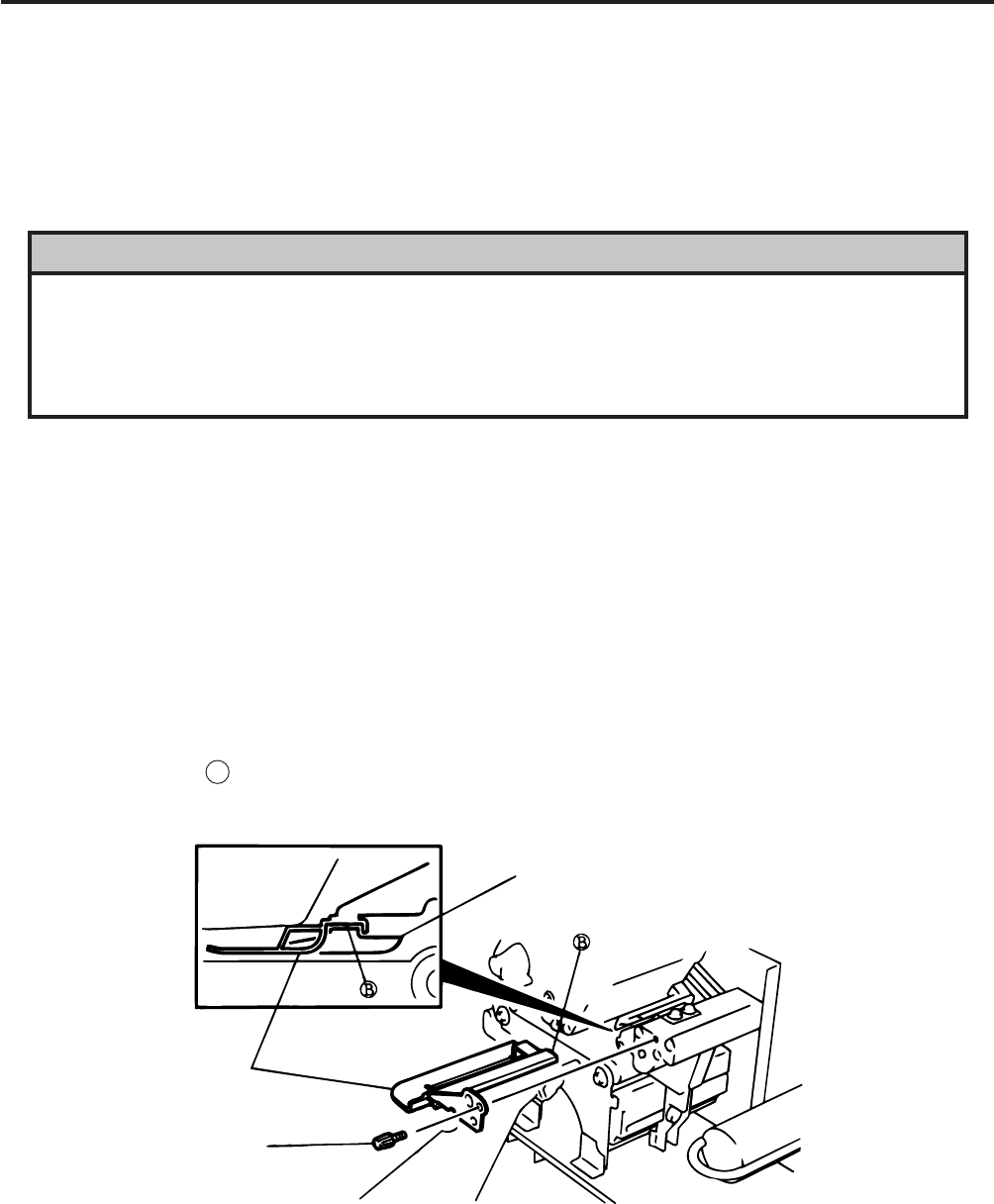

Fig. 9-2

9. Paper jams in the cutter unit can be caused by wear or residual glue from label stock on the cutter. Do

not use none specified media in the cutter. If you get frequent jams in the cutter contact your Authorized

Service representative.

9.2 Covers and Panels

The covers should be cleaned by wiping with a dry cloth or a cloth slightly dampened with a mild detergent

solution.

NOTE: Clean the printer cover with an electrostatic free cleaner for automated office equipment.

9.3 Removing Jammed Paper

1. Turn the power off.

2. Open the top cover.

3. Turn the head lever to position 3, then release the ribbon shaft holder plate.

4. Remove the flanged screw to detach the media guide plate. (See Fig. 9-2.)

5. Remove the ribbon and media.

6. Remove the jammed paper. DO NOT USE any sharp implement or tool as these could damage the

printer.

7. Clean the print head and platen, then remove any further dust or foreign substances.

8. Place the portion B of the media guide plate on the media sensor. Secure the media guide plate with

the flanged screw.

9.2 Covers and Panels

Media Sensor

Media Guide Plate

Flanged Screw

FL-4x 12

WARNING!

1. DO NOT POUR WATER directly onto the printer.

2. DO NOT APPLY cleaner or detergent directly onto any cover or panel.

3. NEVER USE THINNER OR OTHER VOLATILE SOLVENT on the plastic covers.

4. DO NOT clean the panel covers or the supply window with alcohol as it may cause them to

discolor, loose their shape or develop structural weakness.