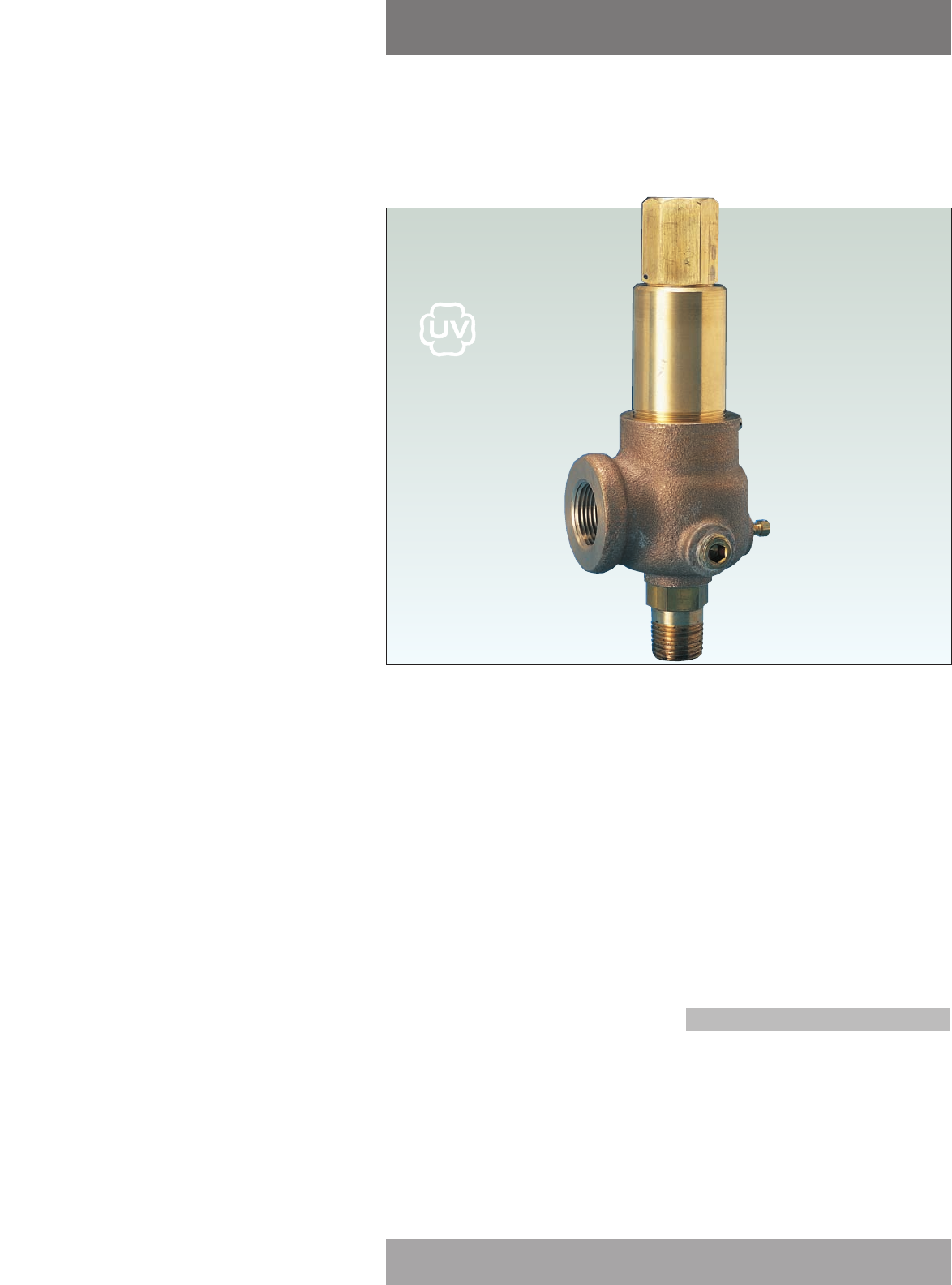

Models 912, 913, 918 and 919 ASME Section VIII, Air/Steam/Gas/Liquid,

‘UV’ National Board Certified. Also available for Vacuum Service

Model 912

Kunkle Safety and Relief Products

Tyco reserves the right to change product design and specifications KUKMC-0392

without notice. Copyright © 2002 by Tyco International Ltd. 7

Models 910, 911, 912, 913, 916, 917, 918, 919, 920, 921 and 927

Features

•Available with soft seat.

•

Threaded cap is standard (back pressure

tight).

• Hex on valve nozzle provides for easy

installation.

• Single control ring offers easy

adjustability of blowdown.

• Pivoting disc design corrects

misalignment and offers exceptional

performance.

• Guide to nozzle ratio reduces friction.

• Full nozzle design for optimum flow

performance.

• Threaded side outlet for piped off

discharge to eliminate fugitive emissions.

Options

• Threaded cap.(Variation 01)

• Threaded cap with gag.(Variation 02)

• Plain lever. (Variation 03)

• Plain lever with gag. (Variation 04)

• Plain lever with vibration dampener.

(Variation 05)

•Packed lever. (Variation 06)

•Packed lever with gag. (Variation 07)

Model Descriptions

Model 912: Full nozzle design. SS warn ring

and disc with brass/bronze base. Bronze/

brass body and bonnet.

Model 913: Full nozzle design. Bronze/

brass body and bonnet. 316 SS trim (base,

disc and disc holder).

Model 918: Same as Model 912 except

resilient seat/seal. Superior ‘leak-free’

performance.

Model 919: Same as Model 913 except

resilient seat/seal. Superior ‘leak-free’

performance. Bronze body and bonnet.

316 SS trim (base, disc and disc holder).

Pressure and Temperature Limits

Models 912, 918: – Steam

3 to 250 psig [-0.2 to 17 barg]

1

-320° to 406°F [-195° to 208°C]

Models 913, 919: – Steam

3 to 300 psig [-0.2 to 17 barg]

1

-320° to 425°F [-195° to 219°C]

Models 912, 918: – Air/Gas/Liquid

3 to 300 psig [-0.2 to 21 barg]

-320° to 406°F [-195° to 208°C]

Models 913, 919: – Air/Gas/Liquid

3 to 900 psig [-0.2 to 62 barg]

-320° to 425°F [-195° to 219°C]

Vacuum – 6- through 29-inch HG

[200 through 1000 mbarg] – 300°F [149°C]

Maximum back pressure 50 psig [3 barg] -

threaded cap and packed lever

Note

1. ASME standard valves for air or steam

service must have lift lever.For steam boilers

and generators.

Applications

• Air/gas compressors - intercoolers -

aftercoolers.

• Liquid filled pressure vessels/systems -

ASME Section VIII (UV).

• Pressure vessels - containing gas, air,

liquid or steam. Including tanks and

receivers.

•Vacuum systems including pumps, tanks

and equipment.

• Optional materials for low temperature -

cryogenic applications.

• Oil/gas separators.

•Overpressure relief and protection

of pumps, tanks, lines and hydraulic

systems.

• By-pass relief or pressure regulation.