USER’S MANUAL — Please read before using this equipment.

© 2007 Wagan Corporation.

All Rights Reserved.

Wagan and Wagan.com are trademarks used by Wagan Corporation.

13

8000W Power Inverter

By Wagan Tech

www.wagan.com

14

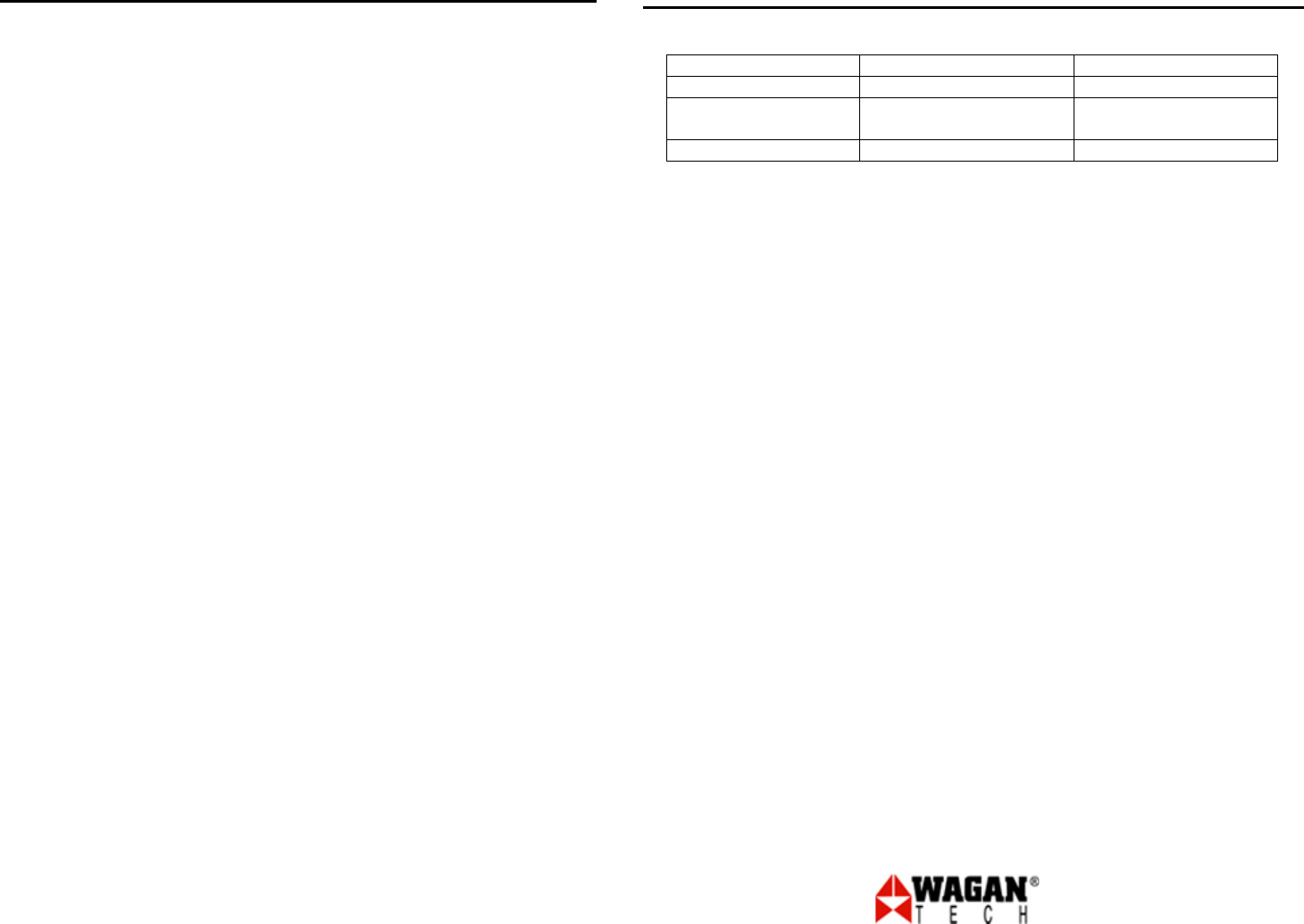

5.4 Fusing requirements

Total AC Watts Negative cables (-) Positive Cables(+)

2500 or lower One One

2500 or more but

less than 5000

Two Two

5000 to 8000 Four Four

NOTE: It is important that for this 8000 watt inverter has main battery fuses

connected to the positive (+) battery cable(s) as close as possible to the connected

battery bank’s positive terminal. The fuse amperage rating must be sized to allow

simultaneous operation of all the AC appliances to be powered, allowing for the

momentary high start-up current r equ irements of inductive loads. Use the

recommended fuse block (fuse holder) and fuse, or an electrical equivalent. ANL

type fuses and fuse holders are readily available from marine supply dealers. The

fuse and fuse holders may be connected in parallel to provide the required

protection. There are larger capacity fuses and fuse holders available. Make sure

that if the inverter is operatin g at 8000 watts that the battery is fused at greater

than 800 amps.

6. CONNECTING THE INVERTER

6.1 General information

Loose connections will result in a severe voltage drop that can cause damage to

the conductors and insulation and cause sparking.

Reverse polarity connection will blow the fuses in the inverter and can cause

permanent damage to the inverter.

The fuses are very important to protect equipment, batteries and personnel. The

fuses protect against battery explosion if the cables that connect to the inverter

accidentally short. READ AND COMPLY WITH THE WARNING BELO W.

Damage caused by reverse polarity will void the warranty.

6.2 Procedure

WARNING

1 Make sure the cables are the proper gage and have the fuse holders as close to

the battery bank’s Pos (+) terminal.

EXPLODING BATTERIES CAN SPRAY MOLTEN LEAD, HOT

SULFURIC ACID AND OTHER METAL AND PLASTIC FRAGMENTS.

BATTERIES THAT ARE CHARGING OR UNDER HIGH DISCHARGE

RATES PRODUCE EXPLOSIVE HYDROGEN GAS INTO THE

SURROUNDING AREA. BE SAFE - FUSE THE BATTERY BANK AND

MAKE SURE THE BATTERIES ARE PROPERLY VENTILATED.

2. Install the fuses in the Pos (+) cable.

3. Make sure the ON/OFF switch located on the front panel of the inverter is in

the OFF (0) position. Disconnect any remote switch from the connector on the

front panel.

DC Cable Gage

4. Locate the Ground Lug Terminal at the rear of the inverter. Connect an

insulated 6 gage copper wire to the terminal. The other end of the ground wire is

connected to a “proper” grounding point. Use the shortest practical length of wire.

Connect this wire to the chassis of your vehicle or to the grounding system in

your boat. In a city, the ground wire can connect to a metal cold water pipe that

goes underground. In remote locations, the ground wire can be connected to an

“earth ground”. This can be an attachment to a six foot long copper clad metal rod

driven into the ground. In the unlikely event of a short circuit, operating the

inverter without proper grounding can result in electrical shock. At the factory,

the negative DC terminals are also electrically connected to the ground terminal.

Minimize cable losses by using the thickest wire available, and the shortest

practical length. If the inverter and the battery are positioned within four feet of

each other, a minimum of 0 gage (zero gage) insulated copper wire should be

used to make the connections. If the distance is longer than 4 feet, heavier wire

will be required.

Because multiple battery cables are used with this inverter, keep cable gages and

lengths the same. This will ensure that cable losses will be evenly distributed. Use

the following table as a guide to the number of cable connections required. Be

sure to include any surge wattage in determining the cable configurations.

Remember that terminals also have current carrying

limits.