11

2003 Bontrager Service Manual

FREEHUB BODY RUNNING CHANGE

Bontrager rear hubs use an unique freehub body that

in some cases has encountered removal issues. In these

cases, a high amount of torque is necessary to remove or

install the freehub body attachment bolt.

To resolve this problem a running change was made

to the 2001 product line. The older, direct contact style

of freehub body has been replaced with a splined freehub

body attachment. This splined attachment requires less

bolt torque. Since it is a running change, the following

information is necessary to identify which freehub body

is on a wheel.

If there is a date code stamped on the freehub body

it probably uses a splined attachment. If there is no date,

it is a threaded attachment. After May 2000, both styles

of freehub bodies (both attachment types) will have this

date mark.

These different styles of freehub bodies are not inter-

changeable.

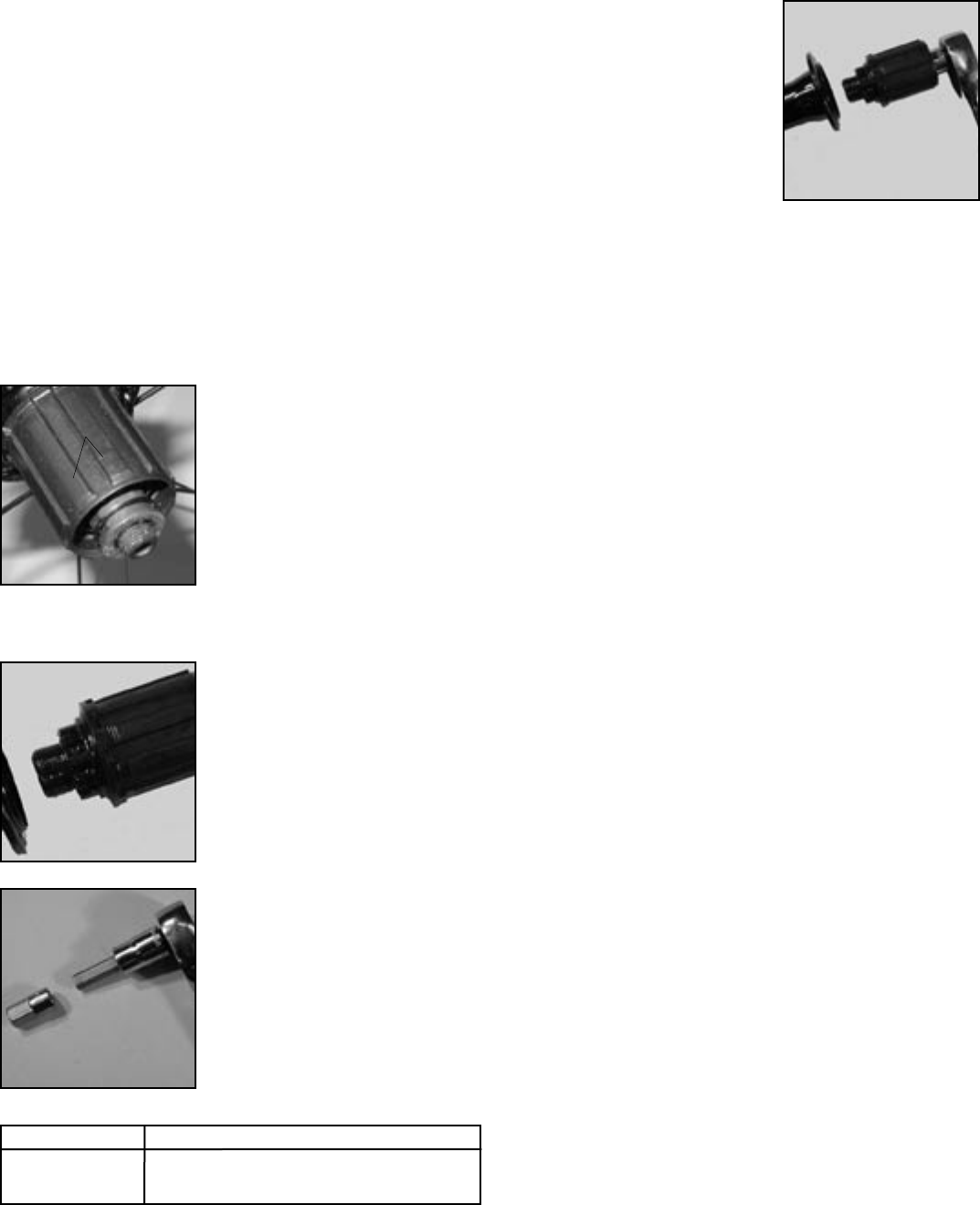

Identification of freehub bodies

Threaded freehub body

With the older, threaded

freehub body, there are two

identifiers. First, there is a

CNC machine line approximately

10mm from the outside end of

the freehub body (Fig. 1).

Second, the thread-attached

freehub body is designed to be

removed with a 12mm allen

wrench.

Splined freehub body

The newer, splined attach-

ment (Fig. 2) freehub body has

no CNC line. Further, it is

designed to use an 11mm allen

wrench for removal. A special

adapter (TCG #211338) is made

which attaches to an 8mm allen

wrench to fit the 11mm allen

head of the freehub attachment

bolt (Fig. 3).

In addition, as a running

change the new hub bodies will

include a 6-digit part number

embossed on the outside of the

hub shell where it is plainly vis-

ible. All hubs with the part num-

ber visible use the splined free-

hub body.

INSTALLATION AND REMOVAL

If the freehub body is worn or damaged, replace it.

Removing the freehub body

1. Follow the Disassembly

instructions for the hub. Remove

the axle, and then the right side

bearings.

2. Determine the correct size

of allen wrench to engage the

freehub body attachment bolt.

3. Unthread the bolt in a

counter-clockwise direction

(standard threading).

Installing the freehub body

1. Carefully clean the mating surfaces and threads of

the freehub body, hub shell, and attachment bolt.

2. Lubricate the threads of the attachment bolt with

Wrench Force™ synthetic grease, or a similar product.

3. Carefully engage the threads of the freehub body

attachment bolt into the hub shell. The bolt is steel, and

the hub is aluminum, so cross-threading the bolt will

result in destruction of the hub shell.

4. With the new splined freehub engagement, make

sure the splines are aligned as you tighten the attachment

bolt.

For the older, threaded style freehub body, tighten the

freehub attachment bolt to 350 lb•in (40Nm).

For the newer, splined design, tighten the freehub

attachment bolt to 400 lb•in (45.2 Nm).

Freehub body information (non-DT Swiss)

Fig. 3

Fig. 2

Fig. 4

Fig. 1

CNC line

Description TCG Part #

Freehub tool, 211338

11mm adapter