3

Printer Adjustments

42

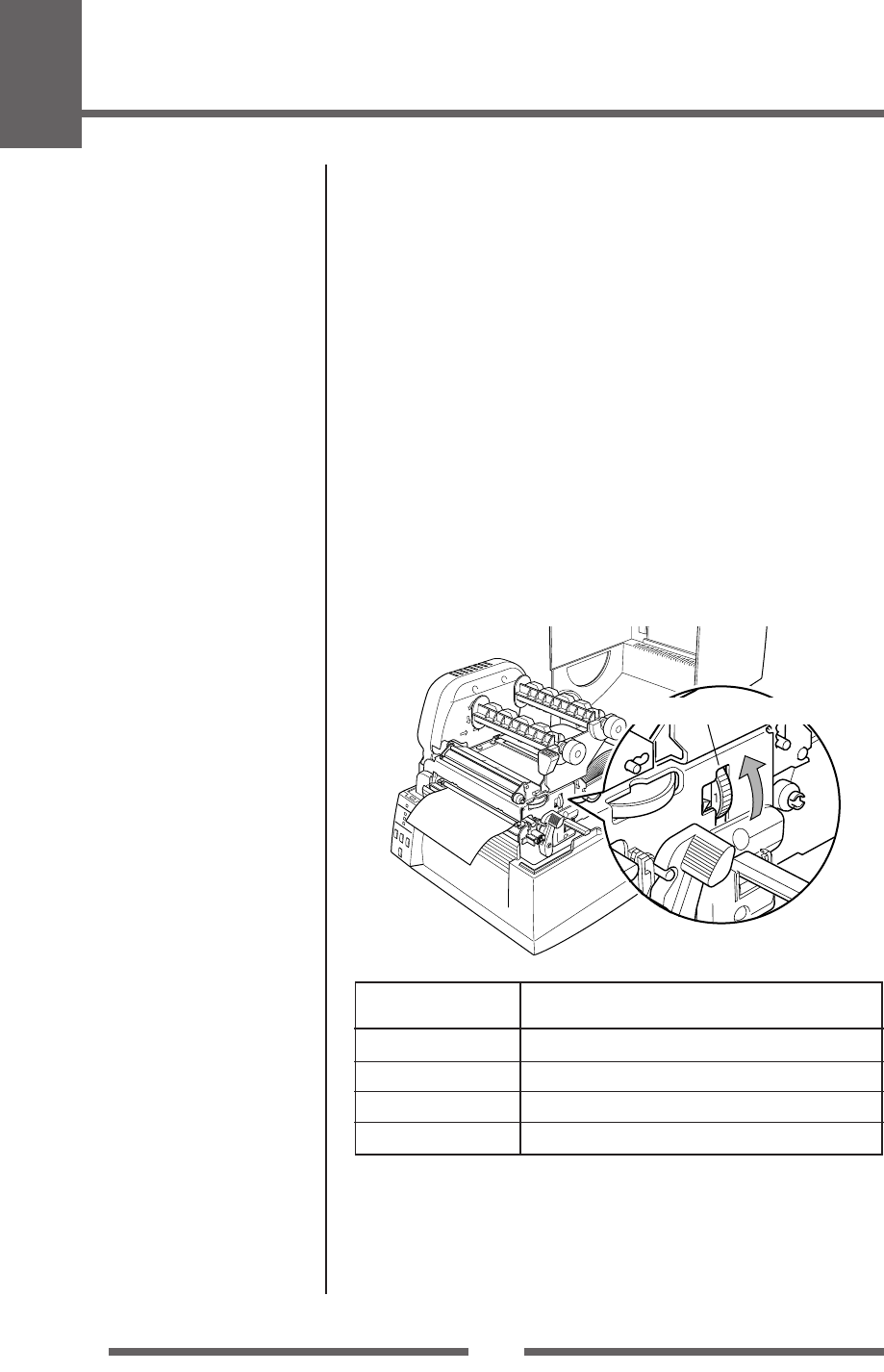

Media Thickness Adjustment

It may be necessary to adjust the printer according to the thickness of the

media being used. This can be done easily by rotating the media adjustment

dial to improve the print quality.

• Poor print quality across the complete printout means wrongly set media

thickness. See this section.

• Poor print quality on one side of a printout means wrongly set media width.

See next section.

When using standard label media, high quality media or direct

thermal media

Adjust while performing test printing by turning the dial from the smallest

number on the dial to the largest number on the dial one step at a time.

When using thicker media (tags, card, etc.)

Adjust while performing test printing by turning the dial from the smallest

number on the dial to the largest number on the dial one step at a time.

• When shipped from the factory, it is set at dial 1.

• The offset adjustment varies according to the thickness and the hardness

of the media.

Media thickness adjustment dial

Installing the Media (p.24)

Self Print Mode (p.30)

Media Thickness

Suggested media type

Dial Position

0 Direct thermal media (thin media)

1 Standard Label media, Direct thermal media

3-5 Thicker backing paper labels

6-9 Cards, tags, thicker media stock.

* These values are guidelines. The exact media being used must be matched

with the correct media thickness adjustment position.