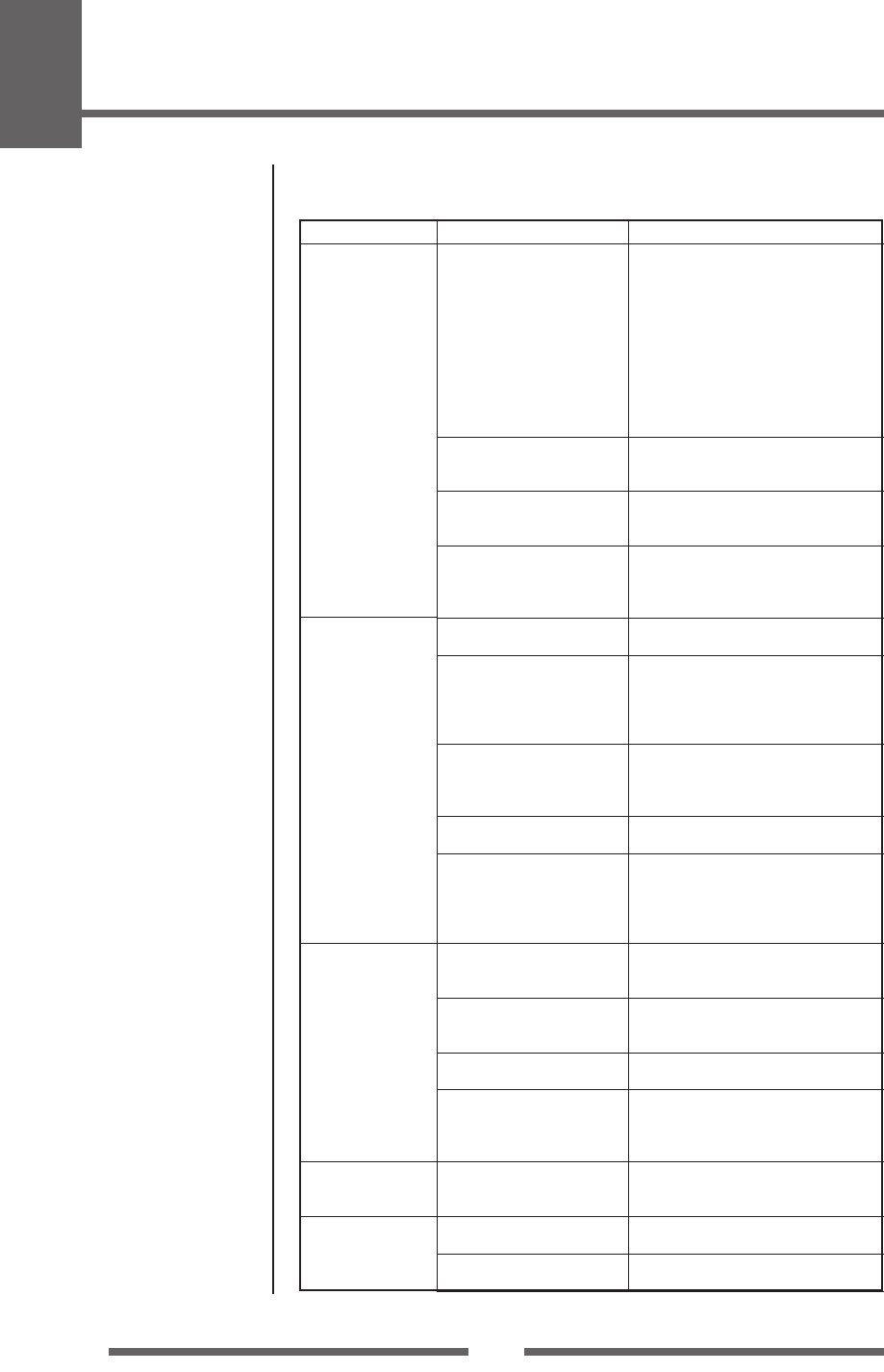

4

Troubleshooting

48

Indication

The printer is not

printing neatly.

The printing position

changes.

The ribbon is wrinkled

The ribbon slips

(ribbon dirt is

produced.)

The ribbon does not

wind.

Check

4) Is the thermal printhead

dirty?

Is a label stuck to the head.

5) Is the recommended

ribbon or a ribbon of the

same type used?

6) Is the thermal printhead in

the correct position for the

media that is used?

7) Is the printer’s head

pressure balance correct

for the width of the media

that is used?

1) Are the media and the

ribbon correctly set?

2) Is the platen dirty?

Is it deformed?

3) Are the data contents and

the command signals from

the host appropriate?

4) Are the menu values set

appropriately?

5) Are the sensitivities of the

media sensors appropriate

for the media that is used?

1) Is the ribbon tension

suitable for the ribbon that

is used?

2) Is the ribbon used correctly

balanced to the right and

left?

3) Is the printing density too

high?

4) Are the media and ribbon

the recommended

products or equivalent

products?

1) Is the ribbon tension

suitable for the ribbon that

is used?

1) Is the ribbon set in the

correct course?

2) Is the ribbon winding

direction reversed?

Corrective action

4) If it is dirty, remove the dirt with the

attached head cleaner.

If a label is stuck to the head, remove

it.

Note: Do not use a metal object to

remove a label stuck to the inside of

the printer. (This may damage the

thermal printhead .) If adhesive label

material is stuck to the print head,

remove it with a soft cloth soaked in

ethyl alcohol.

5) Use the recommended ribbon or a

ribbon of the same type.

6) Adjust the offset of the thermal

printhead with the media thickness

adjustment dial.

7) Adjust the thermal printhead pressure

with the media width adjustment dial.

1) Correctly set the media and the ribbon.

2) If it is dirty, clean it with ethyl alcohol.

If it is deformed, replace it.

Note: Consult with the dealer that

supplied the printer concerning the

replacement.

3) If an error message is displayed, check

the content of the software and the

communication status set by the host

computer.

4) Set the correct menu values using the

operating panel or the host computer.

5) Set the media sensitivity to appropriate

values.

If this does not solve the problem,

change the “Sensor level” that is set in

the “System setup.”

1) Adjust the tension with the ribbon

tension adjustment knob.

2) Adjust the left - right balance with the

ribbon balance adjustment knob.

3) Set the appropriate printing density

using the menu or control software.

4) Use the recommended products or

equivalent products. If this does not

correct the problem, contact a service

representative.

1) Adjust the tension with the ribbon

tension adjustment knob.

1) Set the ribbon in the correct course.

2) Set the correct winding direction.

Media Thickness

Adjustment (p.42)

Media Width

Adjustment (p.43)

Installing the Media (p.23)

Setting method (p.26)

Cleaning (p.46)

LED Functions (p.21)

Menu Setting Table

(p.36)

Ribbon Balance

Adjustment (p.45)

Ribbon Tension

Adjustment (p.44)

Setting the Ribbon

(p.26)

Ribbon Tension

Adjustment (p.44)

Setting the Ribbon

(p.26)