Specifications and Technical Data

59

8.0 SPECIFICATIONS AND TECHNICAL DATA

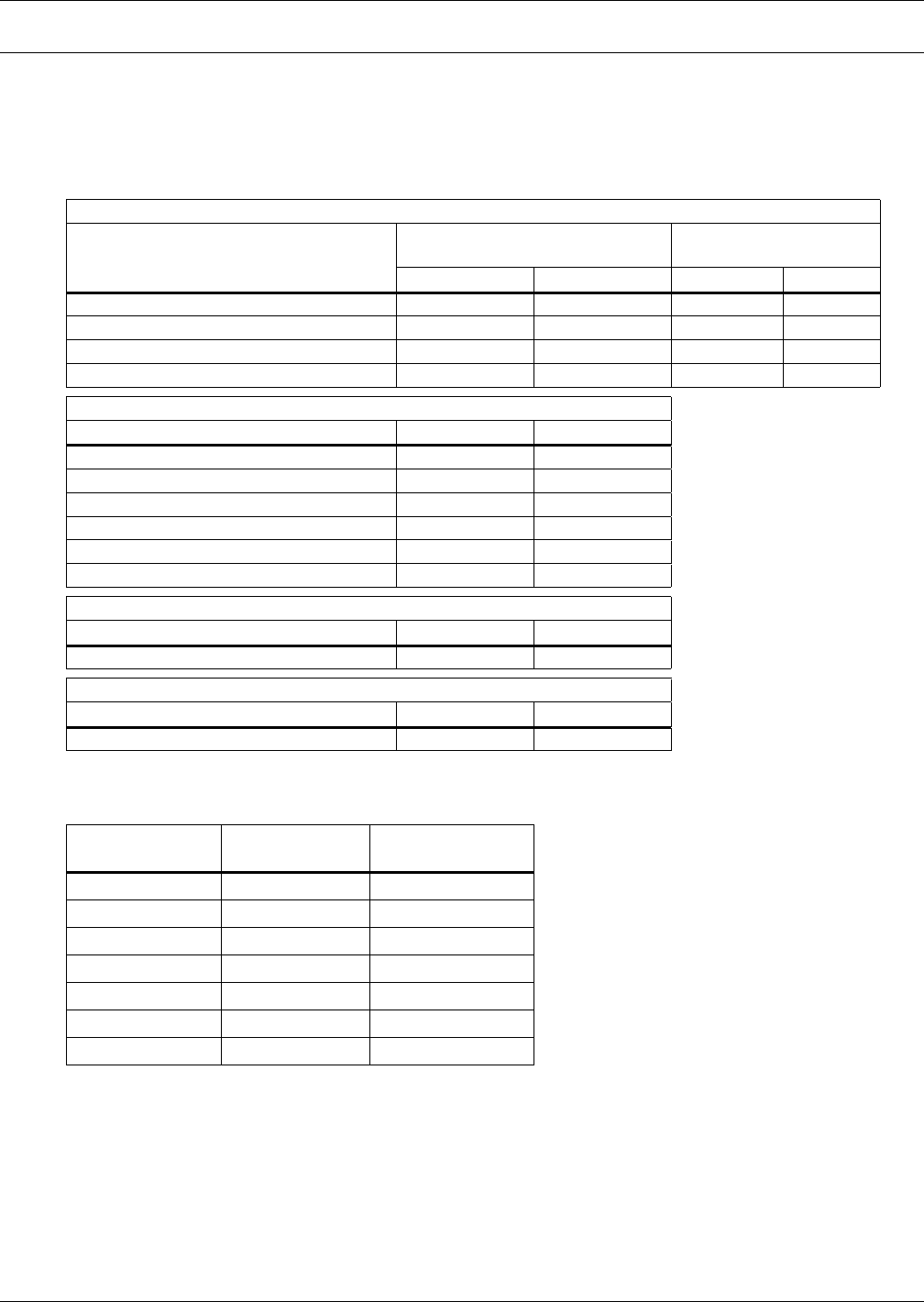

8.1 Lug Size and Torque Requirements

Use commercially available solderless lugs for the wire size required for your application. Refer to

Table 27. Connect wire to the lug using tools and procedures specified by the lug manufacturer.

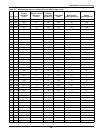

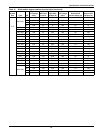

Table 27 Torque specifications

Nut and Bolt CombinationS

Bolt Shaft Size

Grade 2 Standard

Electrical Connections

with Belleville Washers

Lb-in N-m Lb-in N-m

1/4 53 6.0 46 5.2

5/16 107 12 60 6.8

3/8 192 22 95 11

1/2 428 22 256 29

Circuit Breakers With Compression Lugs (For Power Wiring)

Wire Size or Range Lb-in N-m

#6 - #4 100 11

#3 - #1 125 14

1/0 - 2/0 150 17

3/0 - 200 MCM 200 23

250 - 400 MCM 250 28

500 - 700 MCM 300 34

Circuit Breakers With Compression Lugs (For Power Wiring)

Current Rating Lb-in N-m

400 - 1200 Amps 300.00 34.00

Terminal Block Compression Lugs (For Control Wiring)

AWG Wire Size or Range Lb-in N-m

#22 -#14 3.5 to 5.3 0.4 to 0.6

NOTE: Use the values in this table unless the equipment is labeled with a different torque value.

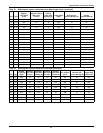

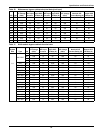

Table 28 Battery torque rating

Battery

Initial Torque

in-lb (N-m)

Annual Torque

in-lb (N-m)

UPS12-100MR 40 (4.5) 32 (3.48)

UPS12-140MR 40 (4.5) 32 (3.48)

UPS12-200MR 40 (4.5) 32 (3.48)

UPS12-270MR 40 (4.5) 32 (3.48)

UPS12-310MR 65 (7.4) 52 (5.88)

UPS12-370MR 65 (7.4) 52 (5.88)

UPS12-475MR 110 (12.4) 110 (12.4)