Product Data Document

420DS-4c

July 19, 2007 - Page 8

Bristol

®

ControlWave

®

LP

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

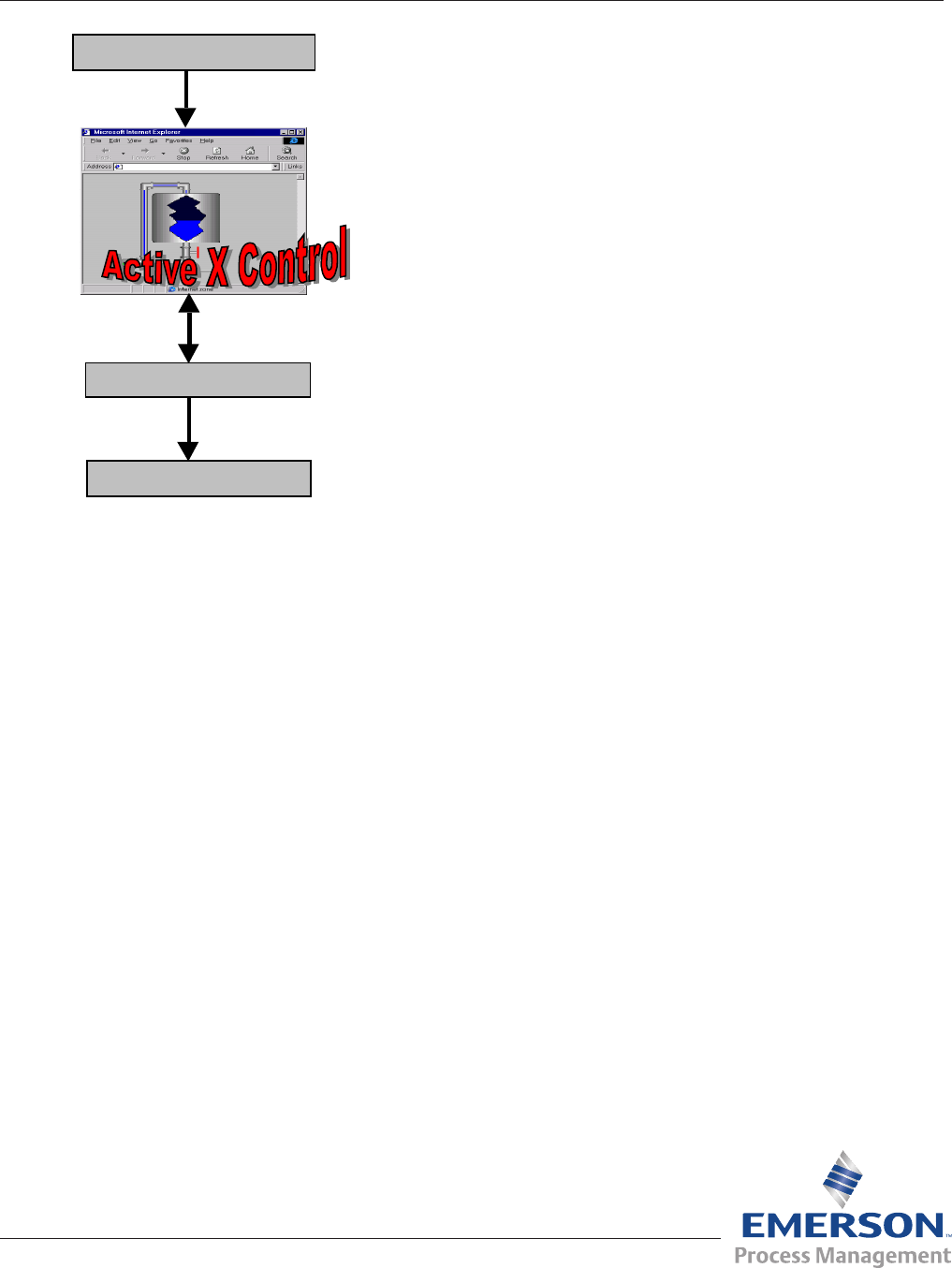

The IP compliant ControlWave opens the door for

owner controlled access via Web Pages. Any ge-

neric web page builder can be employed to create

user dened pages to access ControlWave. The

web pages are populated with these pre-congured

Active X controls.

Software Required

Microsoft’s Internet Explorer

Emerson’s Bristol Active X Controls

Emerson’s Bristol Data Server

OpenBSI Utilities

High Historical Data Integrity

The ControlWave Historical Data Collection sys-

tem provides time-stamped historical data storage

in ControlWave nonvolatile Flash memory. The

historical data is collected, through OpenBSI, on a

schedule or demand basis and converted to .CSV

and ODBE compliant le formats for use spread-

•

•

•

sheet and database reports. If data is missed due

to a communication failure, it is collected when the

communication is reestablished and the PC histori-

cal database is backlled with the missing data.

This distributed historical database architecture

proveides the greatest data reliability and integrity

during communication or PC downtime.

Another important historical feature is the Audit

storage and collection system. The audit trail is a

le stored in ControlWave Flash memory containing

signicant events and time-stamped alarms. The

alarms stored in the Audit system provide a histori-

cal archive in addition to the real-time alarm report-

ing system. This le is also collected through Open-

BSI and presented as a text le in the PC. This

Archive Collection – collection and storage to

disk of the ControlWave archive data

Audit Collection - collection and storage to disk

of the ControlWave audit data.

Exports data les to third party, .CSV & ODBC

applications

DDE compliant for use with other popular

Windows applications

OPC Server

With industry demand for open standards,

ControlWave answers the call by embracing tech-

nologies that open the door for maximizing your

efciency and productivity. The OPC standard was

developed by the OPC Foundation comprised of

hardware and software suppliers from the process

control community. OPC allows the engineer to

select best in class hardware and software with con-

dence in their interoperability. Our OpenBSI OPC

Server was among the rst to comply with the OPC

Foundation alarm and event server specication.

OPC Data Access 1.0a & 2.0 compatible

Windows 98/NT & 2000

Compatible with both ControlWave and Network

3000 systems

32 bit multi-threading, multi-processor design

Automatic database builder

•

•

•

•

•

•

•

•

•

Generic Web

Page

Data Server

Control

Wave