RTC - 72421 / 72423

Page - 21 MQ - 162 - 03

Application notes

1. Notes on handling

This module uses a C-MOS IC to realize low power consumption. Carefully note the following cautions when

handling.

(1) Static electricity

While this module has built-in circuitry designed to protect it against electrostatic discharge, the chip could still be

damaged by a large discharge of static electricity. Containers used for packing and transport should be

constructed of conductive materials. In addition, only soldering irons, measurement circuits, and other such

devices which do not leak high voltage should be used with this module, which should also be grounded when

such devices are being used.

(2) Noise

If a signal with excessive external noise is applied to the power supply or input pins, the device may malfunction or

"latch up." In order to ensure stable operation, connect a filter capacitor (preferably ceramic) of greater that 0.1

µ

F

as close as possible to the power supply pins ( between V

DD

and GND ). Also, avoid placing any device that

generates high level of electronic noise near this module.

∗

Do not connect signal lines to the shaded area in the figure shown in Fig.1 and, if possible, embed this area in a

GND land.

(3) Voltage levels of input pins

Apply signal levels that are as close as possible to V

DD

and ground, to all pins except the CS1 pin. Mid-level

potentials will cause increased current consumption and a reduced noise margin, and can impair the functioning of

the device.

Since it is likely that power consumption will increase excessively and operation cannot be guaranteed, the setting

of the voltage range of V

IH2

and V

IL2

at the CS1 pin should be such that the system is designed so that it is not

affected by ripple or other noise.

Note that the CS1 pin cannot handle a TTL interface.

(4) Handling of unused pins

Since the input impedance of the signal pins is extremely high, operating the device with these pins open circuit

can lead to malfunctions due to noise. Pull-up or pull-down resistors should be provided for all unused signal pins.

The N.C. pins should be connected to either V

DD

or GND, to prevent noise. If not using the ALE pin, connect it

directly to V

DD

.

2. Notes on packaging

(1) Soldering heat resistance

If the temperature within the package exceeds +260

°

C, the characteristics of the crystal oscillator will be degraded

and it may be damaged. The reflow conditions within our reflow profile is recommended.

Therefore, always check the mounting temperature and time before mounting this device. Also, check again if the

mounting conditions are later changed.

∗

See Fig.

2 profile for our evaluation of Soldering heat resistance for reference.

(2) Mounting equipment

While this module can be used with general-purpose mounting equipment, the internal crystal oscillator may be

damaged in some circumstances, depending on the equipment and conditions. Therefore, be sure to check this. In

addition, if the mounting conditions are later changed, the same check should be performed again.

(3) Ultrasonic cleaning

Depending on the usage conditions, there is a possibility that the crystal oscillator will be damaged by resonance

during ultrasonic cleaning. Since the conditions under which ultrasonic cleaning is carried out (the type of cleaner,

power level, time, state of the inside of the cleaning vessel, etc.) vary widely, this device is not warranted against

damage during ultrasonic cleaning.

(4) Mounting orientation

This device can be damaged if it is mounted in the wrong orientation. Always confirm the orientation of the device

before mounting.

(5) Leakage between pins

Leakage between pins may occur if the power is turned on while the device has condensation or dirt on it. Make

sure the device is dry and clean before supplying power to it.

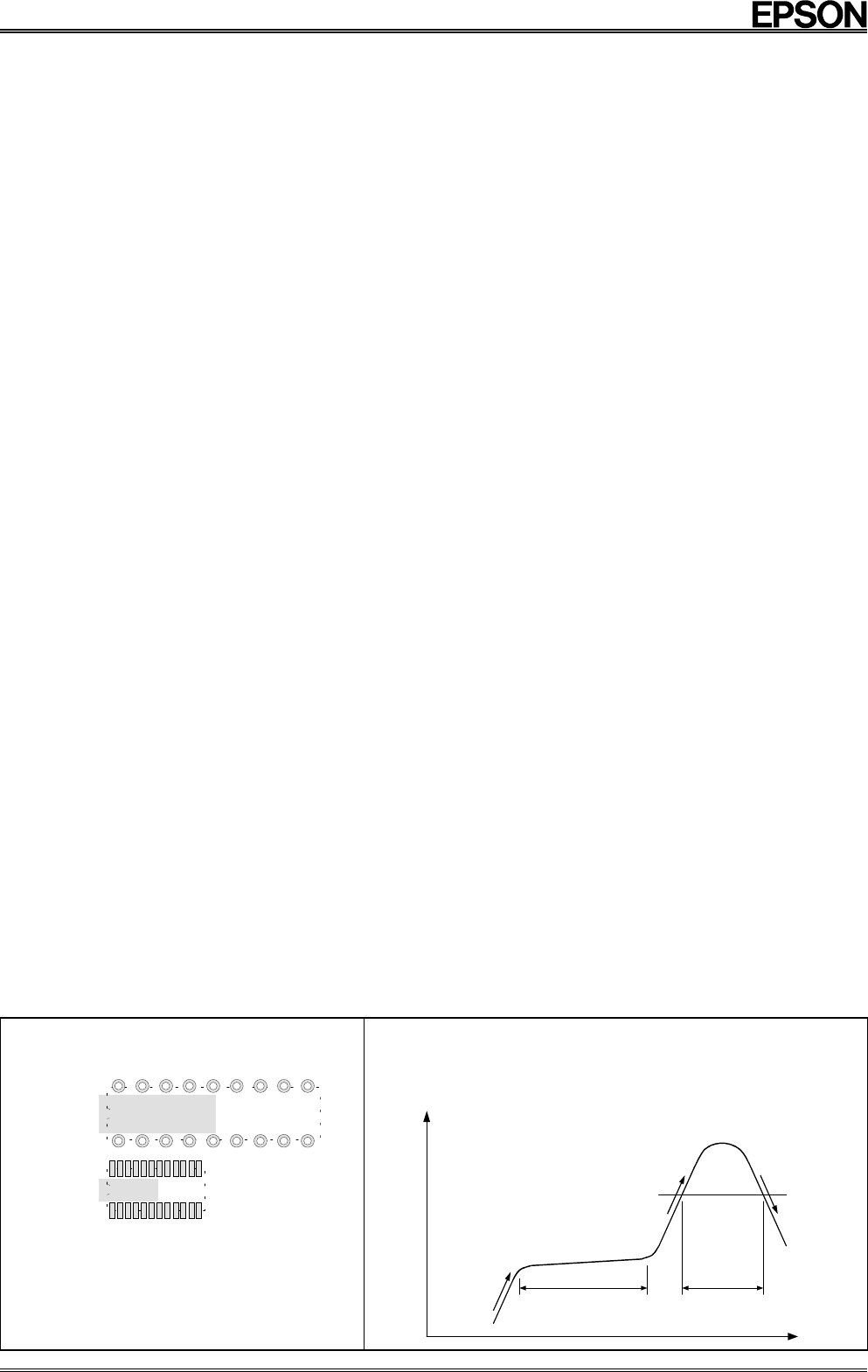

Fig. 1: Example GND Pattern

Fig. 2 Reference profile for our evaluation of Soldering heat resistance.

RTC-72421

RTC-72423

+1

∼

+5

°

C /

s

100 s

Pre-heating area

−

1

∼

−

5

°

C / s

time [ s ]

Temperature [

°

C ]

+170

°

C +220

°

C

+260

°

C

Max.

+1

∼

+5

°

C /

s

35 s

Stable Melting area