51 Water Street, Watertown, MA 02172 USA

800-422-3006 • 617-923-9900 • Fax 617-923-9911

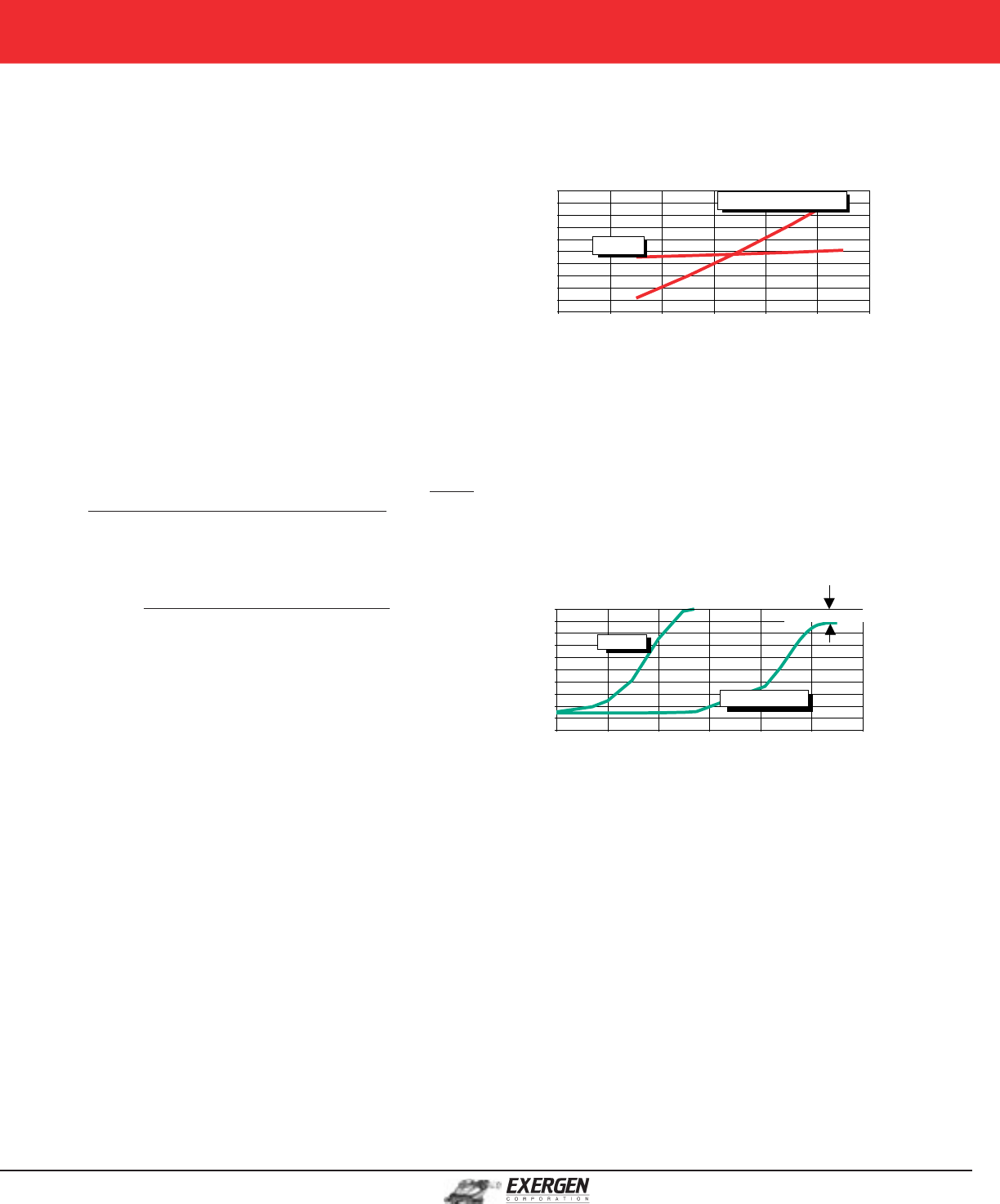

Time Comparison Between D-Series and Contact

Thermocouple for Measuring a 500°F (260°C) Surface

Time from start of Measurement (sec)

deg F

0

100

200

300

400

500

0.001 0.01 0.1 1 10 100 1000

D-Series

Contact Probes

260

200

150

90

deg

C

Contact Error

D-Series Handheld IR Scanners

3. User adjustment errors

A setting of emissivity = 0.9 on an IR “gun” from one

manufacturer will not necessarily match that of another IR

“gun” from another manufacturer. There are no standards

set in the industry on the precise measurement and

meaning of “emissivity”.

Also, Quality Assurance programs should not rely upon any

instrument that allows users to alter the instrument settings

and to let it display whatever the user wishes.

4. Background reflection errors

Even if emissivity is constant (see #2), there are still errors

induced by changing ambient temperatures. For example,

with emissivity = 0.9, ambient reflections account for 10% of

the signal that the IR “gun” will see. If ambient changes, the

IR “gun” will display a different target temperature,

even if

the target remains at the same temperature.

5. Contact errors

Thermocouples, RTDs, thermistors and other contact

devices

only measure their own temperature. They do not

measure surface temperature. Published “Accuracy”

specifications are for the probes only, not the surfaces they

must measure. Users must guarantee that the probes are

brought to the same temperature as the surface. Can you

guarantee that your probes are brought to the same

temperature as the targets to be measured?

6. Friction heating errors

For moving surfaces, a contact probe is prone to frictional

heating. The size of the error is dependent on the rough-

ness of the surface, the speed, the coating on the probe,

and so on. It is impossible to control all the variables.

7. Heat sinking errors

For most non-metals, heat sinking errors can be quite large. The heat transfer rate of the metal leads required on

“contact probes” conducts heat faster than the target material can replace, resulting in unknown and fairly large

errors. In general, the less dense the target material, the larger the heat sinking error with a contact probe.

8. Time based errors

Contact temperature probes are slow. The temperature of a target can change more quickly than most probes,

resulting in errors in real time measurement.

Figure 3. D-Series remains accurate even if the

ambient temperature varies, while conventional IR

devices have considerable inaccuracies.

Effect of Ambient Temperature on Target Reading

for 100 °F (38°C) Target with .8 Emissivity

Ambient T (F)

Target T (F)

90

94

98

102

106

110

0 20406080100120

Conventional Infrared

D-Series

38

43

32

(C)

4 162738

Figure 4. D-Series measures surface temperature in a

fraction of a second, while contact probes (thermocouples,

RTD’s, thermistors, etc.) require many minutes to acheive

equilibrium. Contact probes always have a residual error

due to imperfect heat transfer from the surface to probe.