TECHNICAL DATA

6

Channels

6 control channels (normal operation)

or

8 control channels (extended operation)

Inputs

• RS232/423 (PMX).

• DMX 512.

Rotating mirror head

• Head rotatable through 360° on

projector housing.

•

Graduated scale for easy and accurate

positioning.

• Anchorage for safety wire.

•

Mirror of ultra-high luminous efficiency.

• Movement by means of three stepper

motors, controlled by microprocessor.

• Travel:

- PAN = 150°

- TILT = 110°

• Speed:

- PAN = 0,4 sec (150°)

- TILT = 0,3 sec (110°)

• Resolution:

- PAN = 0.6° (150°)

- TILT = 0.4° (110°)

Safety Devices

• Bipolar circuit breaker with thermal

protection.

• Automatic break in power supply in

case of overheating or failed operation

of cooling system.

• Automatic disconnection of the power

supply at the opening of the re-lam-

ping cover.

• Two fixing points for safety rope.

Cooling

Forced ventilation with axial fans.

Body

• In die-cast and extruded aluminium.

• Epoxy powder painting.

•

Four side handles for transportation

(standard feature on Touring Version

only).

Support

• Steel bracket with epoxy powder

painting.

• Six installation positions, 25mm (1”)

apart.

• Bracket adjustable through 100° with

graduated scale to assist positioning.

Working position

Operation in any position.

Weights and dimensions

• HMI 1200 TV: 36.4 kg (80 lbs 1 ozs)

• HMI 1200: 35.5 kg (78 lbs 2 ozs)

• HMI 575: 29.5 kg (64 lbs 14 ozs)

• Mirror head: 3.1 kg ( 6 lbs 13 ozs)

Power supply available

• 230V 50Hz

• 240V 50Hz

• 208V 60Hz

• 200V 50Hz

• 200V 60Hz

The projector is designed to operate at

mains frequency and voltage given on

the electrical data label on the back of

the appliance.

Lamp

Metal halide type supplied with special

built-in power supply unit.

• Type HMI 1200W/GS

- Cap SFc 15,5-6

- Colour temperature 6.000 K

- Luminous flux 110.000 lm

- Average life 750 h

- Any working position

• Type HMI 575W

- Cap SFc 10-4

- Colour temperature 6.000 K

- Luminous flux 49.000 lm

- Average life 750 h

- Any working position

Input power

• HMI 1200 Touring Version:

1500VA at 220V 50Hz

(correction factor 140µF standard)

• HMI 1200 Version:

3000VA at 220V 50Hz

• HMI 575 Version:

1500 VA at 220V 50Hz

Motors

9 stepper motors, operating with micro-

steps, totally microprocessor controlled.

Optical unit

• Base in die-cast aluminium.

• Twin lens condenser.

•

Spherical reflector with a high luminous

efficiency.

Lens unit

• Standard: 1:2,5/250 mm.

• Optional: 1:3,3/300 mm.

• Optional: 1:1,6/160 mm

(to be fitted internally of projector).

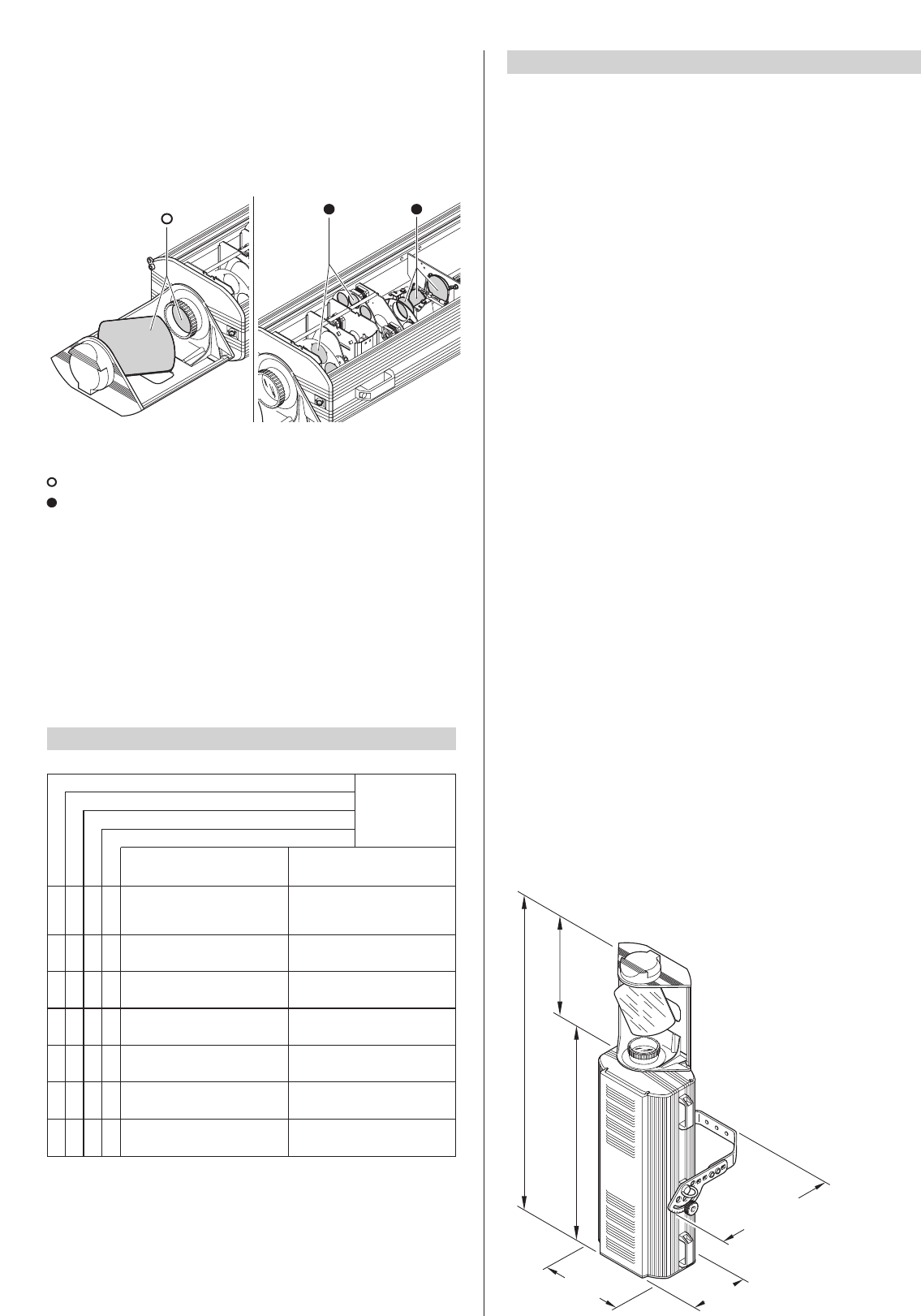

HMI 575= HMI 1200=

HMI 575= HMI 1200=

365

(14.4")

330

(12.99")

235

(9.25")

435

(17.1")

360

(14.2")

954

(37.56")

829

(32.64")

1.230

(48.42")

1.105

(43.5")

6

• Periodical cleaning

To keep optimum efficiency and functionality over time, it is vital to periodically clean

the parts where dust and grease can accumulate.

The frequency with which to carry out the following operations depends on several

factors, such as the number of movements of the effects and the quality of the work

environment (air humidity, dustiness, saltiness, etc.).

To remove dirt from the lenses and filters, use a soft cloth dampened with any liquid

detergent for cleaning glass.

Never use solvents or spirits.

Parts requiring frequent cleaning.

Parts requiring monthly cleaning.

Once a year it is recommended to submit the projector to qualified technical personnel

for non-routine maintenance consisting of at least the following operations:

- General cleaning of internal parts.

- Restoring lubrication of all parts subject to friction, using lubricants specifically

supplied by Clay Paky.

- General inspection of internal components, wiring, mechanical parts, etc.

- Electrical, photometric and functional tests.

- Any repairs.

TROUBLE SHOOTING

5

No mains supply.

Lamp exhausted or defective.

Check there is power at the

supply socket.

Replace the lamp

(see instructions).

THE PROJECTOR WILL NOT SWITCH ON

TROUBLE

THE ELECTRONICS DO NOT WORK

DEFECTIVE PROJECTION

REDUCED BRIGHTNESS

POSSIBLE CAUSES CHECKS AND REMEDIES

•

••

Signal transmission cable

short-circuited or disconnected.

Replace cables.

•

Wrong coding. Check coding

(see instructions).

•

Defect in electronic circuits. Call an authorized technician.

•

Lenses or reflector broken. Call an authorized technician.

•

Dust or grease deposited. Clean

(see instructions).

••