4 308178

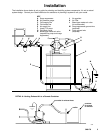

Installation

System Pressure

The maximum fluid working pressure of this surge

suppressor is 100 psi (0.7 MPa, 7 bar) at 100 psi

(0.7 MPa, 7 bar) incoming air pressure. Never exceed

100 psi (0.7 MPa, 7 bar) fluid or air pressure to the

surge suppressor. Do not exceed the maximum

working pressure of any component or accessory used

in the system.

Pressure Relief Procedure

WARNING

PRESSURIZED EQUIPMENT HAZARD

To reduce the risk of serious bodily injury, including

splashing fluid or solvent in the eyes or on the skin,

always follow this procedure before you check,

adjust, clean, or repair any part of the system.

1. Close the air regulator by turning counterclockwise

as far as possible.

2. Disconnect the air supply line to the surge

suppressor.

3. Open the dispensing valve, if used.

4. Open the fluid drain valve to relieve all fluid

pressure; have a container ready to catch the

drainage.

Fluid Compatibility

Be sure all fluids and solvents used are chemically

compatible with the wetted parts and non-wetted parts

shown in the Technical Data section on page 16.

Failure of the diaphragm may cause non-wetted parts

to be exposed to fluid. Always read the fluid and

solvent manufacturer’s literature before using them

with this equipment.

Grounding

WARNING

This equipment must be grounded. Read and

carefully follow the text of FIRE AND EXPLOSION

HAZARD on page 3 before operating the surge

suppressor.

Static electricity is created by the fluid flowing through

the pump and hose. If the equipment is not properly

grounded, sparking may occur, and the system may

become hazardous. Sparks can ignite fumes from

solvents and the fluid being pumped, dust particles,

and other flammable substances, whether you are

pumping indoors or outdoors, and can cause a fire or

explosion and serious bodily injury and property

damage.

If you experience any static sparking or even a slight

shock while using this equipment, stop pumping

immediately. Do not use the system again until the

problem has been identified and corrected.

To reduce the risk of static sparking, ground the pump,

surge suppressor, and all other equipment used or

located in the pumping area. Check your local

electrical code for detailed grounding instructions for

your area and type of equipment. Ground all of this

equipment:

D Pump: See your separate pump instruction

manual.

D Surge suppressor: Secure a ground wire (Y) to the

surge suppressor with the grounding screw (Z)

located on the side of the housing. See Fig. 1.

Connect the clamp end of the ground wire to a true

earth ground. To order a ground wire and clamp,

order Part No. 208950.

D Air and fluid hoses: Use only grounded hoses with

a maximum of 500 ft (150 m) combined hose length

to ensure grounding continuity.

D Air compressor: Follow the manufacturer’s

recommendations.

D All solvent pails used when flushing: Follow the

local code. Use only metal pails, which are

conductive. Do not place the pail on a

nonconductive surface, such as paper or

cardboard, which interrupts the grounding

continuity.

D Fluid supply container: Follow the local code.

0942

Fig. 1

Y

Z