8 308178

Troubleshooting

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 4.

Relieve the pressure.

Check all possible problems and causes before

disassembling the pump or surge suppressor.

PROBLEM

CAUSE SOLUTION

Surge suppressor operates

erratically

Clogged air line or air inlet Inspect; clear.

Air line connected to pressure gauge

port

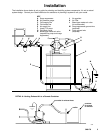

Connect air line to air inlet

(see page 11).

Clogged fluid supply line, fluid inlet or

fluid outlet

Inspect; clear.

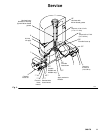

Diaphragm (13 or 21[) ruptured Replace. See page 9.

Unbalanced air pressures between

pump and surge suppressor

Ratio of air inlet pressure to surge

suppressor and air inlet pressure to

pump must be the same as pump ra-

tio, but air pressure to surge sup-

pressor must never exceed 100 psi

(0.7 MPa, 7 bar). See page 7.

Air bubbles in fluid Fluid supply line loose Tighten.

Diaphragm (13 or 21[) ruptured Replace. See page 9.

Manifold o-rings (16) leaking Replace. See page 10.

Fluid in exhaust air Diaphragm (13 or 21[) ruptured Replace. See page 9.

Diaphragm plates (12 or 32) loose or

damaged

Tighten or replace. See page 9.

Damaged shaft (11) or shaft o-rings

(19)

Replace. See page 9.

Pump leaks air or fluid from cover (7) V-clamp (6) is loose Tighten V-clamp. See page 9.

[ Ref. No. 21, the PTFE diaphragm, is used only in Surge Suppressor Models 224892 and 224894.