18

5.5 Occasionally Used Hoists

5.5.1 Hoists that are used infrequently shall be inspected as follows prior to placing in service:

Hoist Idle More Than 1 Month, Less Than 1 Year

: Inspect per FREQUENT Inspection criteria in

Section 5.3.

Hoist Idle More Than 1 Year

5.6 Inspection Records

: Inspect per PERIODIC Inspection criteria in Section 5.4.

5.6.1 Dated inspection reports and records should be maintained at time intervals corresponding to those

that apply for the hoist’s PERIODIC interval per Section 5.2.4. These records should be stored where

they are available to personnel involved with the inspection, maintenance, or operation of the hoist.

5.6.2 A long range chain inspection program should be established and should include records of

examination of chains removed from service so a relationship can be established between visual

observation and actual condition of the chain.

5.7 Inspection Methods and Criteria

5.7.1 This section covers the inspection of specific items. The list of items in this section is based on those

listed in ANSI/ASME B30.16 for the Frequent and Periodic Inspection.

5.7.2 Frequent Inspection - Not intended to involve disassembly of the hoist. Disassembly for further

inspection would be required only if frequent inspection results so indicate. Disassembly and further

inspection should only be performed by a qualified person trained in the disassembly and re-assembly

of the hoist.

5.7.3 Periodic Inspection - Disassembly of the hoist is required. Disassambly should only be performed by a

qualified person trained in the disassembly and re-assembly of the hoist.

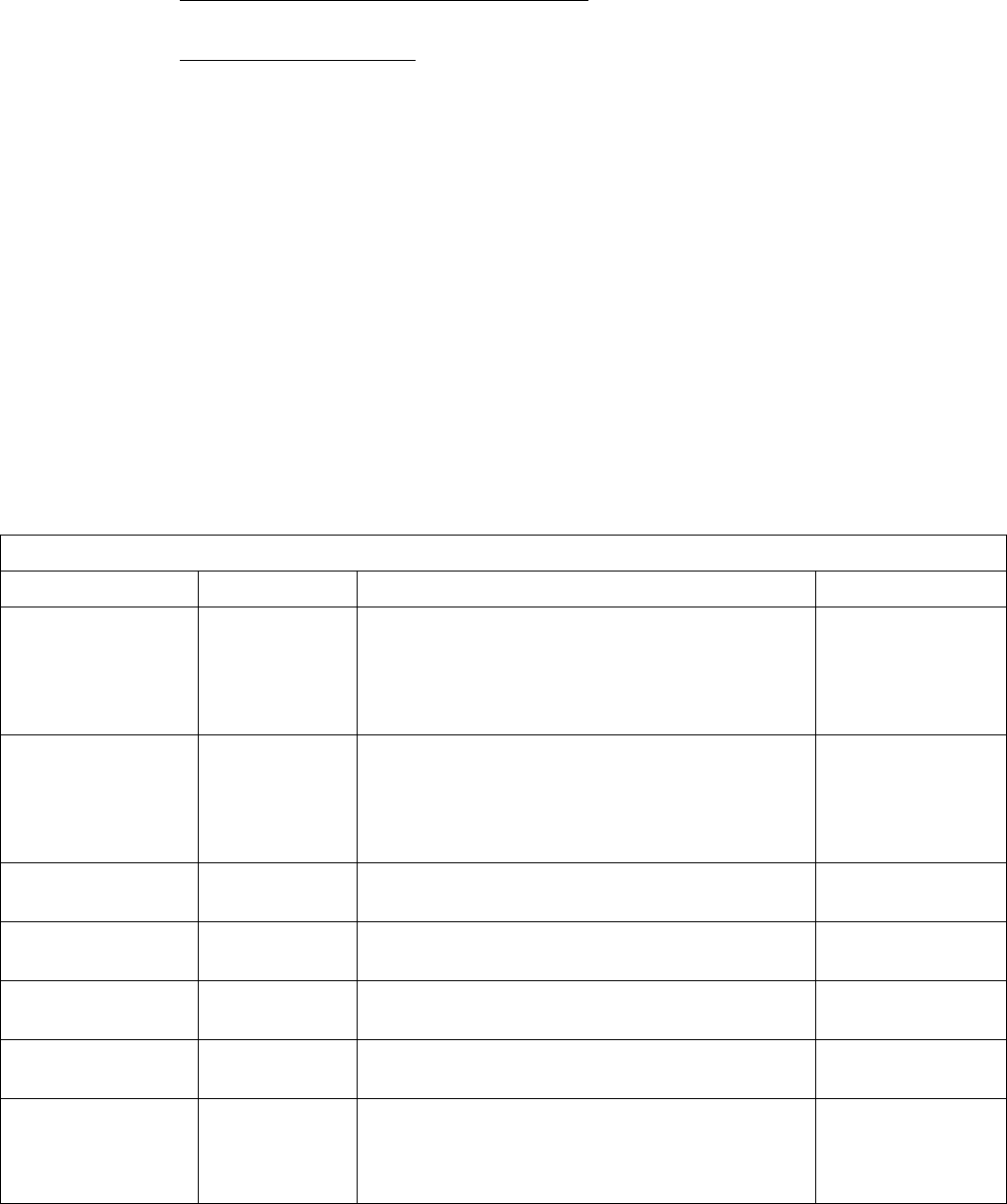

Table 5-3 Hoist Inspection Methods and Criteria

Item Method Discard Limit/Criteria Action

Functional operating

mechanisms.

Visual, Auditory Mechanisms should be properly adjusted and

should not produce unusual sounds when operated.

Components should not be deformed, scarred, or

show significant wear. Refer to Figures 5-2, 5-3 and

5-4.

Repair or replace

as required.

Hooks – Stretch Measure The "k" dimension should not be greater than 1.05

times that measured and recorded at the time of

purchase (See Section 3.4). If recorded "k" values

are not available for hooks when new, use nominal

"k" values from Table 5-4.

Replace.

Hooks – Fretting

wear

Measure The "u" and "t" dimensions should not be less than

discard value listed in Table 5-4.

Replace.

Hooks – Surface

Condition

Visual Should be free of gouges, deep nicks, dents, weld

splatter, and significant corrosion.

Replace.

Hooks –

Deformation

Visual Should be free of twists and deformations. See

Figure 5-1.

Replace.

Hooks – Bent Shank

or Neck

Visual Shank and neck portions of hook should be free of

deformations.

Replace.

Hooks – Swivel Visual, Function Bearing parts and surfaces should not show

significant wear, and should be free of dirt, grime,

and deformations. Hook should rotate freely with no

roughness. See Figure 5-1.

Clean/lubricate, or

replace as required.