33

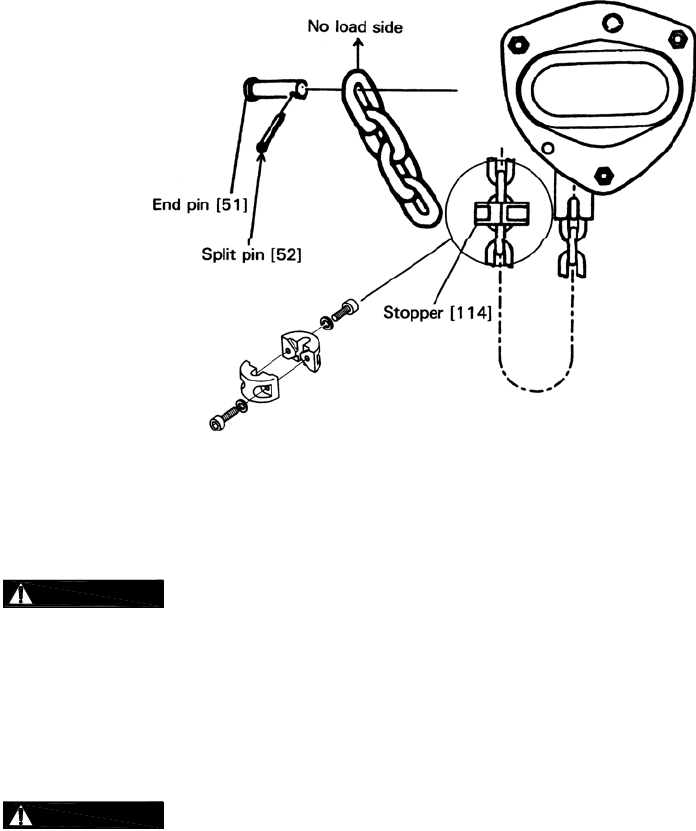

For 10 ton capacity and above:

Connect the no load end of the load chain [47] to the end pin [51] which is to be inserted from gear

case [29] side. Use a split pin [52] to secure the end pin. Assemble stoppers [114] to the ninth link

from the no load end of the load chain by socket bolts and spring washers.

*NOTE: Threaded hole of one stopper shall face to non-threaded hole of the other stopper.

Socket bolt shall be inserted from the non-threaded side.

Figure 6-8 10 Ton & Above Anchorage Assembly

15) Apply machine oil to the pawl pin (in side plate A [11]) and join the pawl spring A [33], and B [33]

and the pawl [34] respectively to it. Fix them with a snap ring [35]. See figure 6-9.

: Make sure the pawl spring is touching the pawl and the snap ring is completely

seated at the bottom of the groove.

16) Attach the friction disc [36] to the pinion [17] shaft (while turning the pawl [34] counterclockwise).

17) Wipe out any dirt on the friction disc [36], friction plates [37] and both sides of the ratchet disc [38]

and check if the oil of the bushing [39] (bushing with oil in it) is adequate. Then place the friction

plate, bushing, ratchet disc and friction plate respectively on the friction disc. (Make sure that the

ratchet disc and the pawl mesh properly). See figure 6-9.

: Since the brake is a “dry system”, NEVER apply oil. Wipe out thoroughly any oil

and dirt on the brake. The gear of the ratchet disc should point at the pawl. Otherwise, the hand wheel

cannot be assembled later. In case the bushing does not have oil inside, soak it in turbine oil for a day.

Install it without wiping the oil.