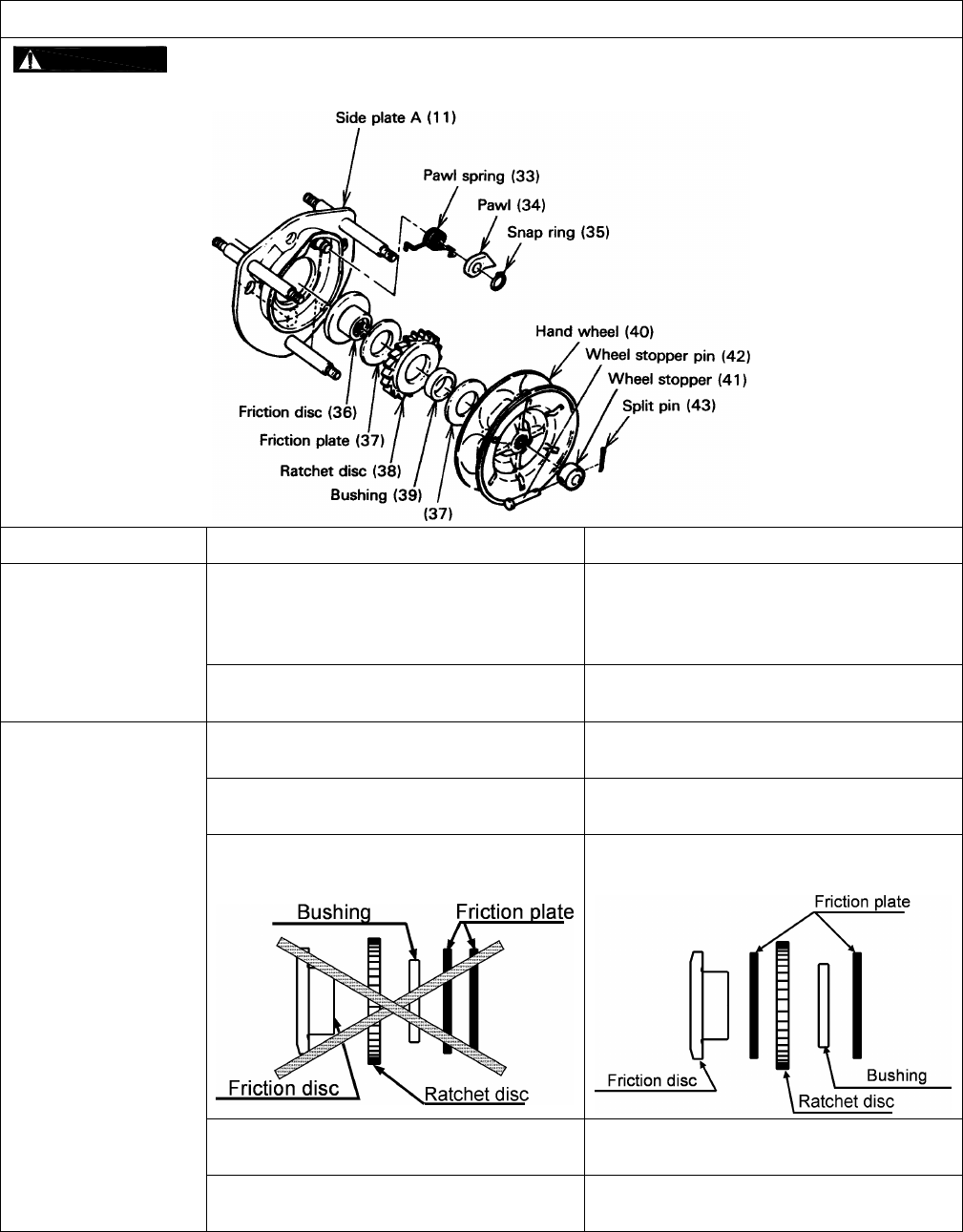

38

Table 7-1 Troubleshooting Guide

Improper braking may cause improper load lowering. The hoist utilizes dry friction discs; do not

apply oil to friction surfaces.

Symptom Cause Remedy

Load will not go down

Over tightened brake

The hoist left under load for a long period

Shock loaded during operation

Pull down hard (possibly with 2 people) on

the hand chain to loosen brake.

Brake rusted tight

Replace the rusty components and perform

hoist maintenance.

Load drifts or slips

when lowering

A foreign object between friction surfaces.

Remove the object and clean the surfaces.

Replace if the friction surface is scarred.

Brake slip caused by significant rust

Replace the rusty component and perform

hoist maintenance.

Mis-assembly of friction plates, i.e. friction

plates missing or at one side as shown.

Reassemble properly as shown and ensure

hoist functions properly before reuse.

Cracked friction plate caused by overload

Replace the friction plate and use the hoist

properly within rated capacity.

Friction plate wear caused by very frequent

and long term use.

Perform hoist maintenance.