16

Glass

Considerations

•

••

•

Light reflectivity and refractivity will directly impact printhead jetting health. UV ink, even while

jetting, will begin to cure in the printhead orifice plate if exposed to stray UV light.

•

••

•

Adjusting the UV Shutter Aperture may help to reduce the amount of errant UV light that is

projected to the printheads. Individual results may vary by reflectivity, refractivity, head height

above the media, opacity, and UV treatment of the glass, so experimentation will be necessary to

find an optimal recipe for curing, adhesion, and image quality.

•

••

•

Depending on the application, High Quality Unidirectional printing with the Leading Lamp

Shuttered may reduce the amount of light projected to the printhead orifice plate and provide

sufficient curing of the inks; which will also reduce the throughput of the print.

•

••

•

To minimize the impact of stray UV light on the printheads, purging and hand cleaning of the

printheads may be necessary to avoid inducing permanent damage.

•

••

•

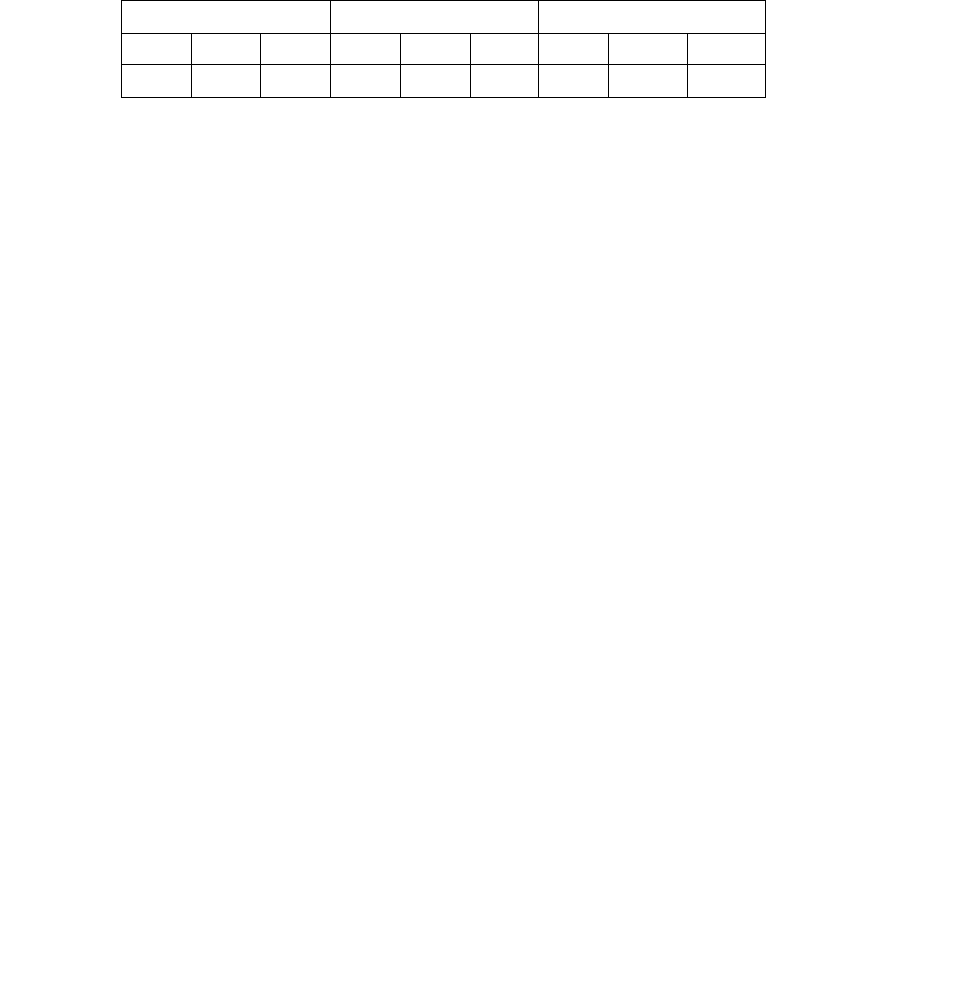

Supported (

) print modes and resolutions:

Recommendations for best results

Preparation

•

••

•

Clean well with a glass cleaner followed by alcohol.

Printing

•

••

•

These materials are heavy in larger sizes. Do not exceed the maximum weight. Flatness, size,

smoothness, and weight will affect the consistency of media feed through the printer.

•

••

•

Cleaning the media as directed and using a color profile that has low ink saturation can reduce ink

adhesion issues found with some end use applications.

•

••

•

Ink saturation and curing are best in Production or High Quality modes. Print reversed from the

server. 1200x600 will provide better coverage than 600x600.

•

••

•

Use low lamp settings.

•

••

•

These materials are usually heavy enough to lie flat, minimal belt vacuum should be used to

prevent additional drag and effect registration.

•

••

•

Use Backlit or a generic color profile, depending on application

Output Handling

•

••

•

Shows fingerprints easily, so handle with gloves at all times.

•

••

•

Depending on the end use application, a post treatment may be necessary to minimize risk of

damage to the UV ink caused by scratching or other surface damage.

1200x600 600x600 600x300

HQ Prod

BB HQ Prod

BB HQ Prod BB