7

Rigid Media

One advantage of flatbed printers over platen printers is that the media drive system provides for a

more consistent advance rate. With the belt-fed system there is little need to perform media feed

calibrations when switching between media types or sizes. Printers that utilize a pinch roller/grit roller

drive mechanism are more sensitive to changes in size or weight, so media feed calibrations are

required when switching between media types.

Some media may be used only up to certain sizes or with certain print modes. For all media types and

sizes, sheet weight should not exceed the published specification for the printer of 125 lbs. (56.7 kg).

For materials between 50-250 lbs. (22-113 kg), choose Heavy when selecting weight in the Media

Wizard when to set the media belt drive motor and media advance interval.

Speed (print mode) limitations may be due either to weight restrictions, as the larger advance motions

do not work as well with the heavier weight materials and sizes, or because certain materials may

deform when subjected to sustained heat of the slower print modes.

Media tables should be level and coplanar to the flat surface of the media belt, appropriately and firmly

latched to the printer with the rollers oriented in such a fashion that they are in line with the print

direction. For printing on rigid media sheets greater than 12 feet (3.66 m) in length, a secondary set of

media tables should be attached to reduce the risk of headstrike damage.

For media with signs of warping or bowing that the vacuum table is unable to reduce, the hold down

rollers should be employed in conjunction with Warped Media Mode to reduce the risk of headstrike

damage.

Media size may impact results and certain sizes of media may not work as well with certain print modes.

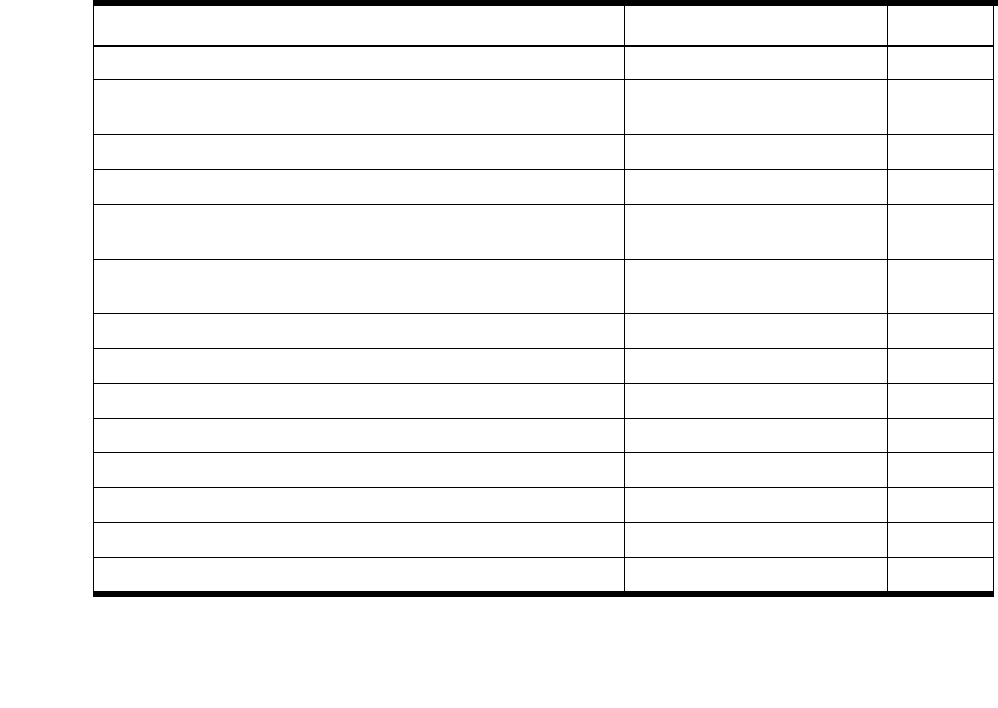

The following table summarizes the maximum supported sizes per media type and points out which

media is likely to be inconsistent with certain print modes. Details can be found in the referred page.

Tests show reliable results with the following rigid media

Table 2 Rigid Media Compatibility shown with the following media:

Media

Supported Print Modes

Details

Acrylic Sheet (Plexiglas

®

and other brand names) All Page 8

Aluminum Composite Materials (Alumacorr

®

, Allumalite

®

, Dibond

®

,

and other brand names)

Limitations Page 9

Card Stock All Page 10

Clear Vinyl Sheet All Page 11

Corrugated fiberboard (clayfaced, kraft paper, and bleached), C

flute or smaller

All Page 12

Fluted polypropylene / corrugated plastic (Coroplast

®

, Interplast

®

,

etc.)

Limitations Page 13

Foam board (Fome-Cor, Kappa, etc.) All Page 14

Foamed PVC (Sintra

®

, Komatex

®

, Celtec

®

, etc.) All Page 15

Glass Limitations Page 16

PETG – Clear All Page 17

Plywood / Medium Density Overlay (MDO) Plywood Limitations Page 18

Polycarbonate Sheet (Lexan

®

, Makrolon

®

, Tuffak

®

) All Page 19

Polystyrene Sheet

All

Page 20

Polystyrene-faced foam board (Gatorplast

®

, Gatorplast

®

, etc.) Limitations Page 21