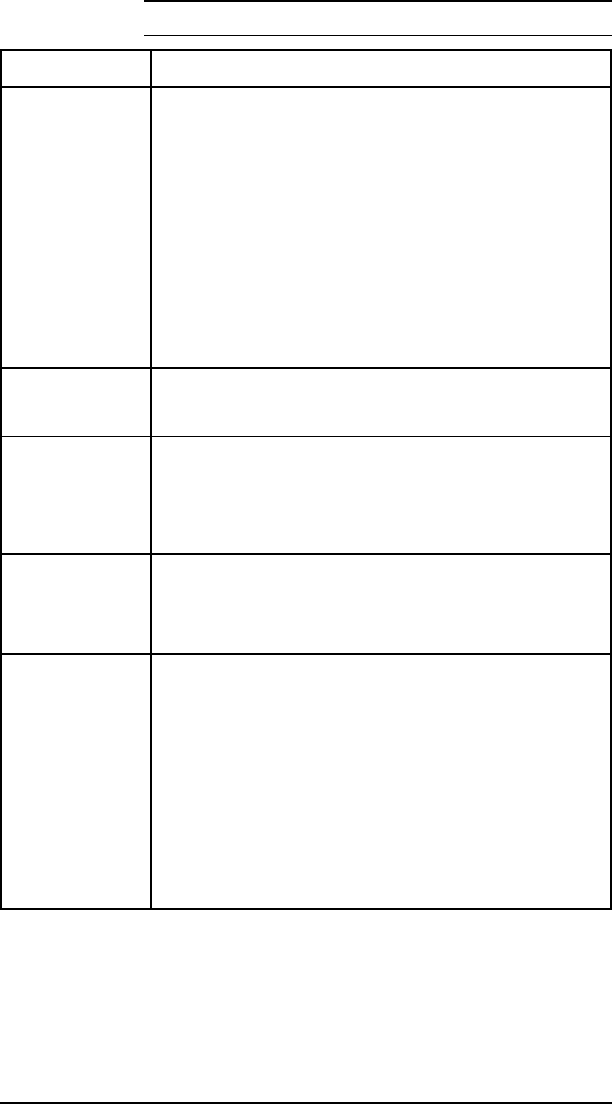

Jam Location Checks and Action Required

Input Area Jams

(Sensed by PS1.)

1. Check that the Transfer Roller is fully seated and shows no

sign of wear.

2. Check that the Toner Cartridge is fully seated.

3. Check that the cassettes are not overfull and the media is

loaded correctly.

4. Ensure that the media meets specs. (media is not too

smooth or rough), and it has been stored properly.

5. Ensure that the paper tray is fully seated (especially if

printing from the Lower Cassette).

6. Ensure that the spring force of the Lower Cassette is set

correctly.

Registration Area

Jams

(Sensed by PS1.)

1. If paper is damaged at the Registration Sensor (PS1),

check that the Transfer Charge Roller is properly seated.

Lower Cassette

Paper Jams

(Sensed by PS1.)

1. The LC Tray (Tray 3) is not fully seated into the printer. Seat

the LC Tray firmly into the printer.

2. The Lower Cassette feed pressure (spring force)

adjustment is incorrect. Set the spring force as shown in

Chapter 3.

Fuser Assembly

Jams

(Sensed by PS3.)

1. Check that the Fuser Pressure Roller Levers are down

(LJ4 and 4 Plus Only).

2. Check that the Exit Sensor Arm (PS3) is free throughout its

travel and that the Exit Sensor Arm is installed correctly.

False Paper Jams

Paper Jam occurs

when the last

sheet of paper is

fed from the tray.

1. PS1, PS3, or PS5 are damaged or mechanically broken.

2. The sensor wires are damaged or disconnected.

3.

4.

The rear door is open.

Paper out sensors in the paper tray or envelope feeder

may be defective, or the sensor flags may be broken or

missing. PS2 is the sensor for the PC Tray (Tray 2), PS4 is

the sensor for the MP Tray (Tray 1), PS6 is the sensor for

the LC Tray (Tray 3), and PS7 is the sensor for the

Envelope Feeder.

Table 7-7

Paper Jam Troubleshooting Checklist

Troubleshooting 7-21