F-23371 Electronic Speed Switch Technical Manual Page 2

2002 Invensys. All Rights Reserved

Relay Contact Rating: 10.0 amperes at 30 Vdc

resistive.

Overspeed Response Time: With the overspeed set

at 4140 Hz and a steady input frequency of 3600 Hz,

then switching the input frequency to 5000 Hz must

result in the overspeed relay operating in 75

milliseconds or less.

2.2 MECHANICAL / ENVIRONMENTAL

Case: Has nickel plated terminals. Humidity and salt

spray resistant. Potted for water protection.

Vibration: 5.0 G’s from 20 to 500 Hz.

Shock: 4 foot drop test.

2.3 MOUNTING INSTRUCTIONS

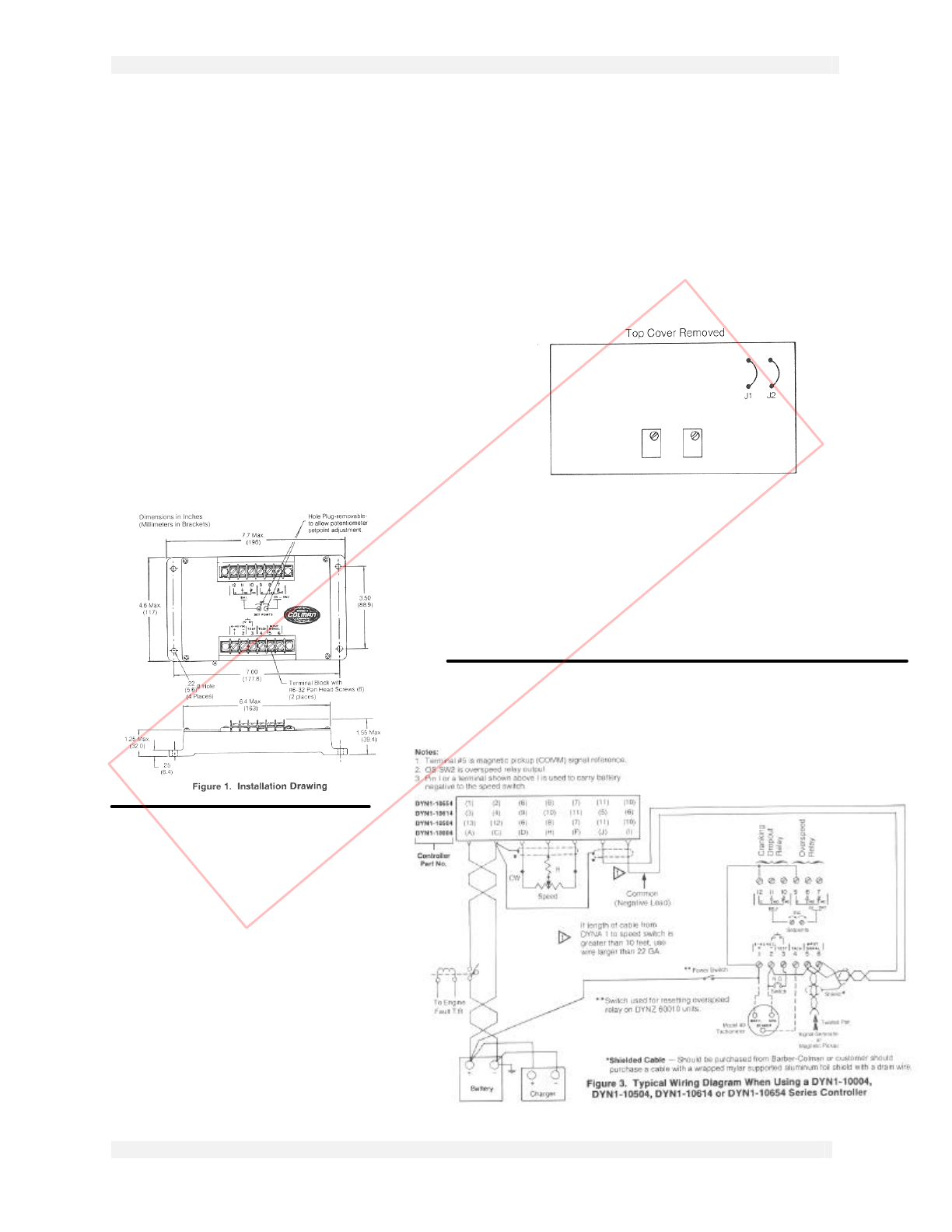

Four mounting holes are provided on the case as

shown in Figure 1. Although the unit can withstand

the normal vibration levels and temperature

excursions encountered, it is a good practice to mount

the unit in a location where these effects are

minimized. The unit should be attached to the

mounting plate with 10-32 screws.

Figure 1. Installation Drawing

3.0 ADDITIONAL FEATURES

3.1 OVERSPEED TRIP TESTING

Overspeed trip testing while the engine is running at

its normal speed can be accomplished by temporarily

connecting terminal 2 to terminal 3. This lowers the

overspeed setpoint of OS-SW2 to 67% of its

set/calibrated value.

3.2 TACHOMETER READOUT

Tachometer readout can be obtained by connecting a

Synchro-Start Model 40 tachometer to terminals 1, 2

and 4 as shown in Figure 3.

Figure 2

3.3 SW1 & OS-SW2 ADJUSTMENT AND

ADJUSTMENT RANGE

l There are two speed trip setpoint adjustments,

SW1 and OS-SW2, located on top of the unit. Turning

the 20 turn potentiometer adjustment clockwise

increases the RPM setting.

Uncontrolled Document

For Historical Reference Only