If it happens, the speed needs to be lowered by one speed level and started again

after

signal on the LCD window.

3. In case of wrinkling or rolling of film due to wrong position of document,

is needed to be keeping pushed in order that document could come out

to the front with buzzer sound.

4. When document is much smaller than film, you should place it in the middle of film

for preventing wrinkle

5. Use cooling fan when you laminate continuously without break and

document is too hot.

The above laminating speed numbers are at the condition on regular voltage with

almost no film tension. There might be the possibility for difference to the

above numbers due to the change of voltage or adjustment of tension.

2. COLD LAMINATING

1. Put cold roll film on upper bar.(Set the same as methord of HOT film for

protect paper of lower part)

2. Pull COLD film, and fix it so that backside protecting paper can be wound on

take-up mandrel clockwise. (Revolve core to make protectingpaper tight a little bit.)

3. Set pressure lever at the proper position following to your lamination condition.

600mm(2ft)

800mm(2.6ft)

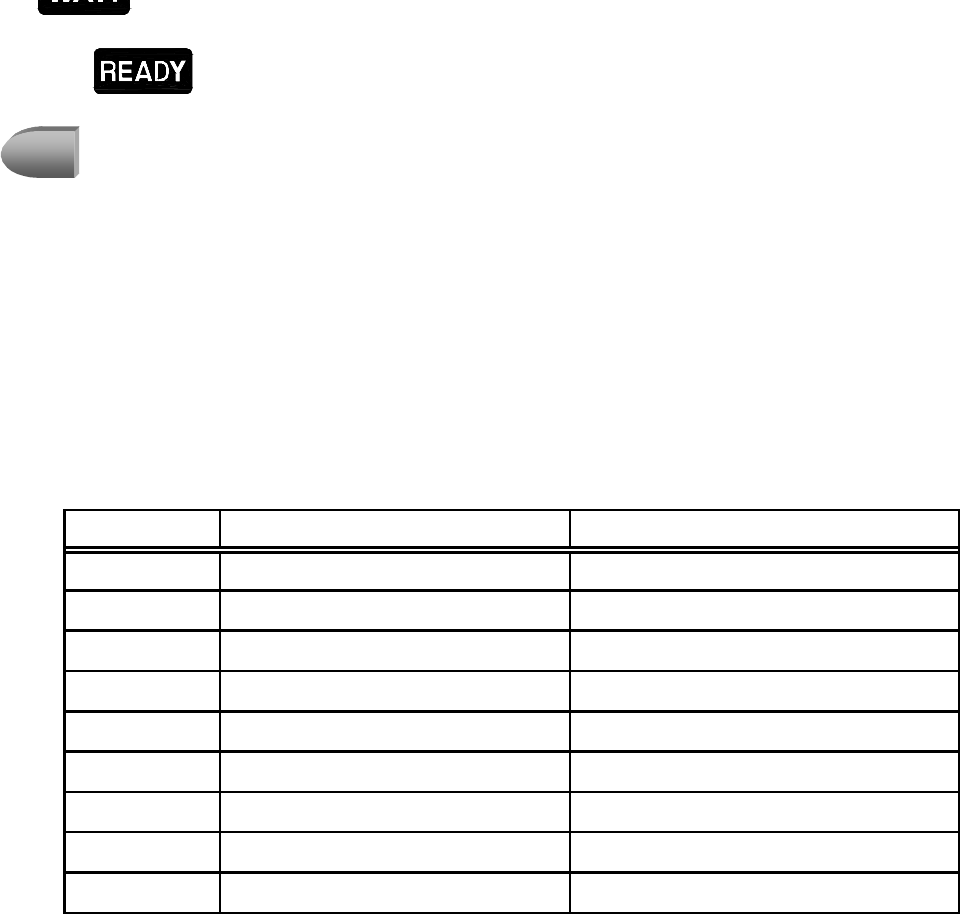

9 2000mm(6.6ft)4000mm(13.1ft)

3600mm(11.8ft)8 1800mm(5.9ft)

2000mm(6.56ft)

2400mm(7.9ft)

2800mm(9.2ft)

3200mm(10.5ft)

1000mm(3.3ft)

1200mm(3.9ft)

1400mm(4.6ft)

1600mm(5.2ft)

5

6

7

SPEED

1

2

3

***Laminating Speed at each level〔mm(ft)/min〕***

4

RSR-685/1050

800mm(2.6ft)

1200mm(3.9ft)

1600mm(5.2ft)

RSH-1050/1650

400mm(1.3ft)

REV

- 21 -