UX-2200CMU/CMC

FO-2150CMU/CMC

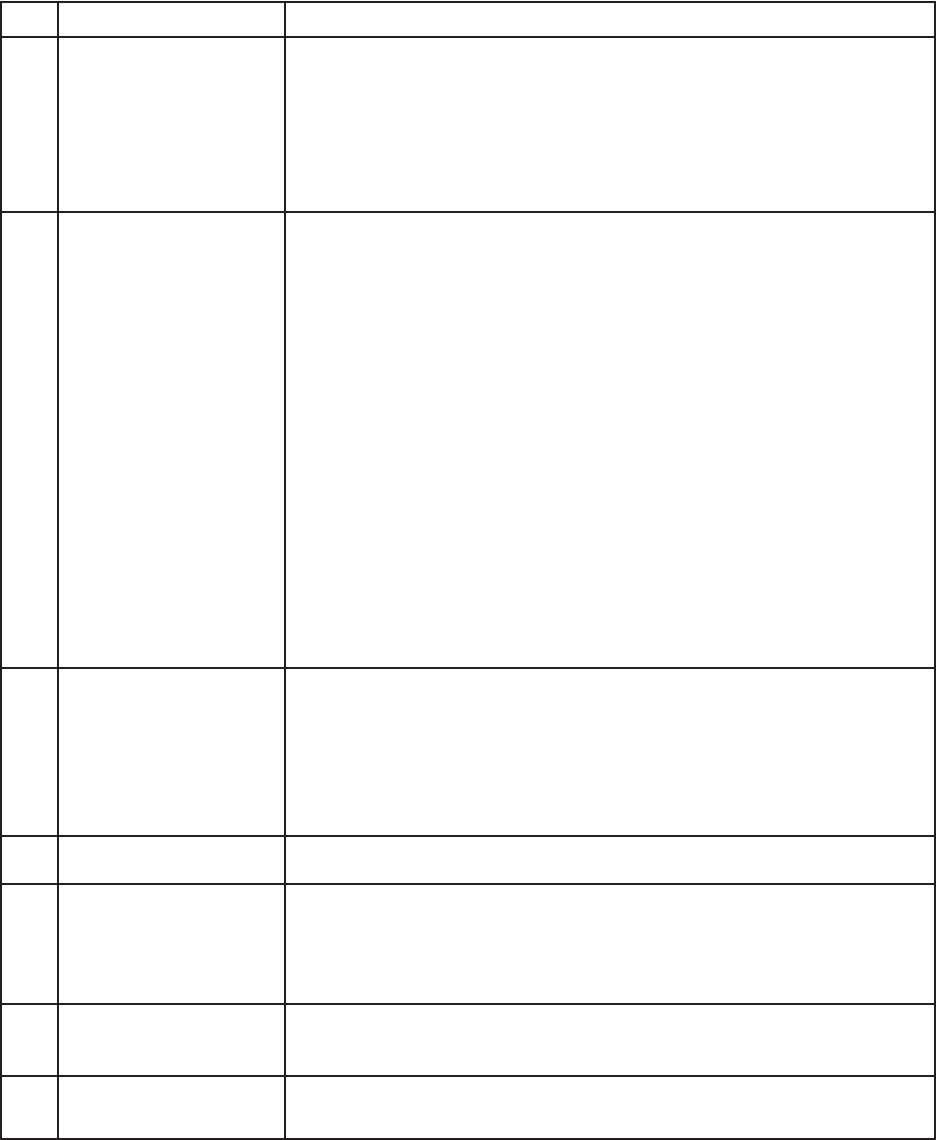

FRU

System Board

Paper Feed Motor

Drive Train Assembly

Auto Sheet Feeder

Mid-Frame Asm

Access Cover Asm

End-of-Forms Flag

and Spring

End-of-Forms Sensor

Action

Turn the printer on and verify the paper feed motor activates. Be sure

the end-of-form sensor lever is in the down position. Turn the printer off

and disconnect CN1 from the system board. Check for motor pins

shorted to the motor housing. If you find a shorted pin,replace the

paper feed motor. If you still have a failure after replacing the paper

feed motor,replace the system board.

A noisy or chattering motor or a motor that fails to turn,can be caused

by an open or short in the motor,an open or short in the motor driver on

the system board,or a bind in the paper feed mechanism. With the

paper feed motor cable CN1 disconnected from the system board,

check for 140 ohms(±7%)between the follwing pins on the motor

: Pin 1 to Pin 2,Pin 1 to Pin 4

280 ohms(±7%)between pins 2 and 4. If the readings are

incorrect,replace the paper feed motor and drive train assembly.

Although the paper feeds in a forward direction only,the paper feed

motor turns in two directions.

If the paper feed motor turns in one direction only,replace the system

board.

Binds in the paper feed motor or gear train can cause intermittent false

paper jam errors. Remove the paper feed motor and check the shaft

for bins.

Also check for loose or worn motor gear.

Check for binds in the gear train and paper feed machanism by remov-

ing the paper feed motor and rotating the large gear by hand . If you

notice a bind,replace the drive train assembly. Check the feed clutch

gear on the left side of the auto sheet feeder. Turn the clutch gear and

check that it rotates freely in one direction and locks when turned in the

opposite direction.

Check the pick rollers for wear.

Check the following for wear:

• Exit roller

• Star rollers

Check for binds or damage. If binds are found,replace the end-of-forms

flag.

Check the sensor for birt. Be sure the sensor lever is in the down

position. If the failure remains,replace the system board.

1

2

3

4

5

6

7

4. Paper Feed Service Check

If your machine does not have paper jam problems, continue with the service check. If your machine does have a

paper jam problem,examine it for the following before you begin the service check:

•

Check the entire paper path for obstructions.

•

Be sure there is not too much paper in the sheet feeder.

•

Be sure the correct type of paper is being used.

•

Check for static in the paper.

– 17 –