UX-2200CMU/CMC

FO-2150CMU/CMC

7. Driver IC

The paper motor and carriage motor require current that cannot be driven directly from ASIC chip.

Motor driver IC provide the additional current and voltage capability.

The driver IC (IC1 and IC2) located near the respective motor connector on the printer PWB also connect back to the

ASIC.

Two additional drivers IC drive 56 nozzles on the cartridge.

These driver ICs , located between the two flex-circuit connector (CN3 and CN4) on the printer PWB , also connected

back to the ASIC.

The out-of-paper sensor do not require drivers, and connect directly to the ASIC.

The Host interface also connects directory to the ASIC.

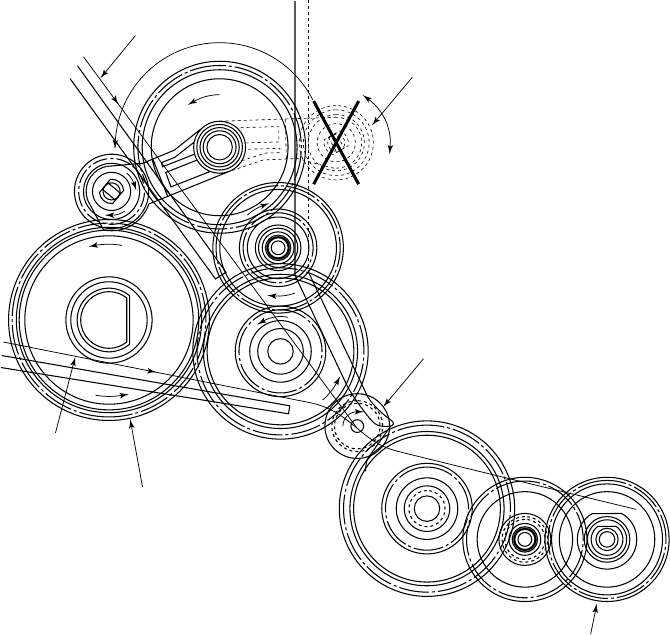

8. Paper Motor

The ASIC controls the paper motor, which is a stepper motor that connects via a 5 pin connector to CN1 on the printer

PWB.

The stepper motor is a 4-coil motor, which must be stepped in proper sequence, requiring four signal lines to initiate

each line.

This is an open-loop system that does not provide feedback to the logic circuit on printer PWB.

The Paper motor drives the recording paper movement.

The planetary gear is changed over according to the rotation direction of this motor.

Accordingly,hand paper feed or automatic paper feed is selected.

(1) Paper feed(paper feed from tray)

The planetary gear turns counterclockwise and is connected to the PU gear,so that paper is fed automatically.

– 4 –

MOTOR GEAR

The automatic paper feed or

hand paper feed is selected by

changing the rotation direction of

motor as a result of changing-over

of this planetary gear.

AUTOMATIC

FEED PAPER

PU GEAR

HAND FEED PAPER

PRINTER FEED GEAR