SVL-A, SVL-B, SVL-C, & SVL-D Self-Contained Material Loaders - Venturi Style 16 of 49

2-4 Connecting the Compressed Air Supply

Before connecting the compressed air supply, check the following:

Check compressed air piping for correct installation and assembly.

Check the fittings, length and quality of the hose connections for

agreement with requirements.

Check all compressed air lines for leakages.

Supply clean, dry (non-lubricated) compressed air with 70-90 psi (5-6 bar)

system pressure.

The air should be free of oil and water.

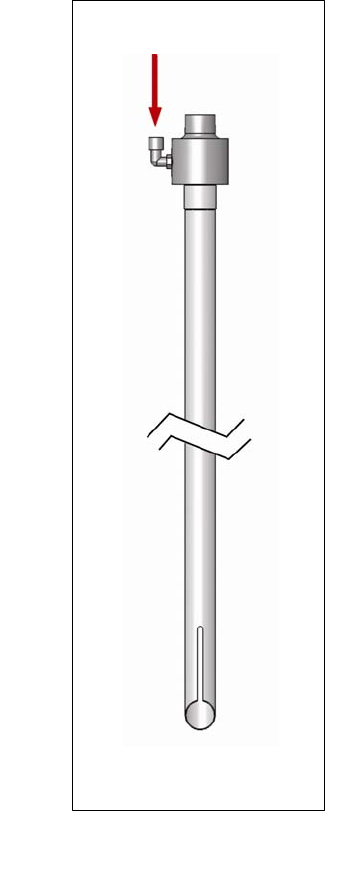

1. Find the compressed air hose, which has been

supplied.

2. Connect it to the venturi and control assembly.

3. Firmly press the compressed-air hose into each

connecting socket.

4. Connect the control assembly to the compressed air

supply.

5. Set the pressure on the pressure reducer at 70-90 psi

(5-6 bar).

Note: Unit requires 25 SCFM at 80 psig if continuously run.

Typical air consumption is 8-10 scfm at 80 psig. Max.

input pressure 145 psi (10 bar).

WARNING! Make sure that the PLANT supply air lines are

large enough to provide required air flow and line

pressure. Failure to provide adequate air flow

and line pressure will result in conveying

performance issues.

Figure 2.10: Venturi Assembly