SVL-A, SVL-B, SVL-C, & SVL-D Self-Contained Material Loaders - Venturi Style 30 of 49

Chapter 5: Maintenance

Preparations

Please observe the maintenance intervals.

Before starting maintenance work, clean the equipment of oil, fuel or

lubricants.

Ensure that materials and incidentals required for operation as well as spare

parts are disposed of properly and in an environmentally sound manner.

Use only original manufacturer spare parts.

Keep record of all maintenance and repair procedures.

Caution! Disconnect the equipment from main electrical supply before

starting maintenance procedures to ensure that it cannot be

switched on unintentionally. Depressurize all compressed air

piping of the equipment before starting maintenance work.

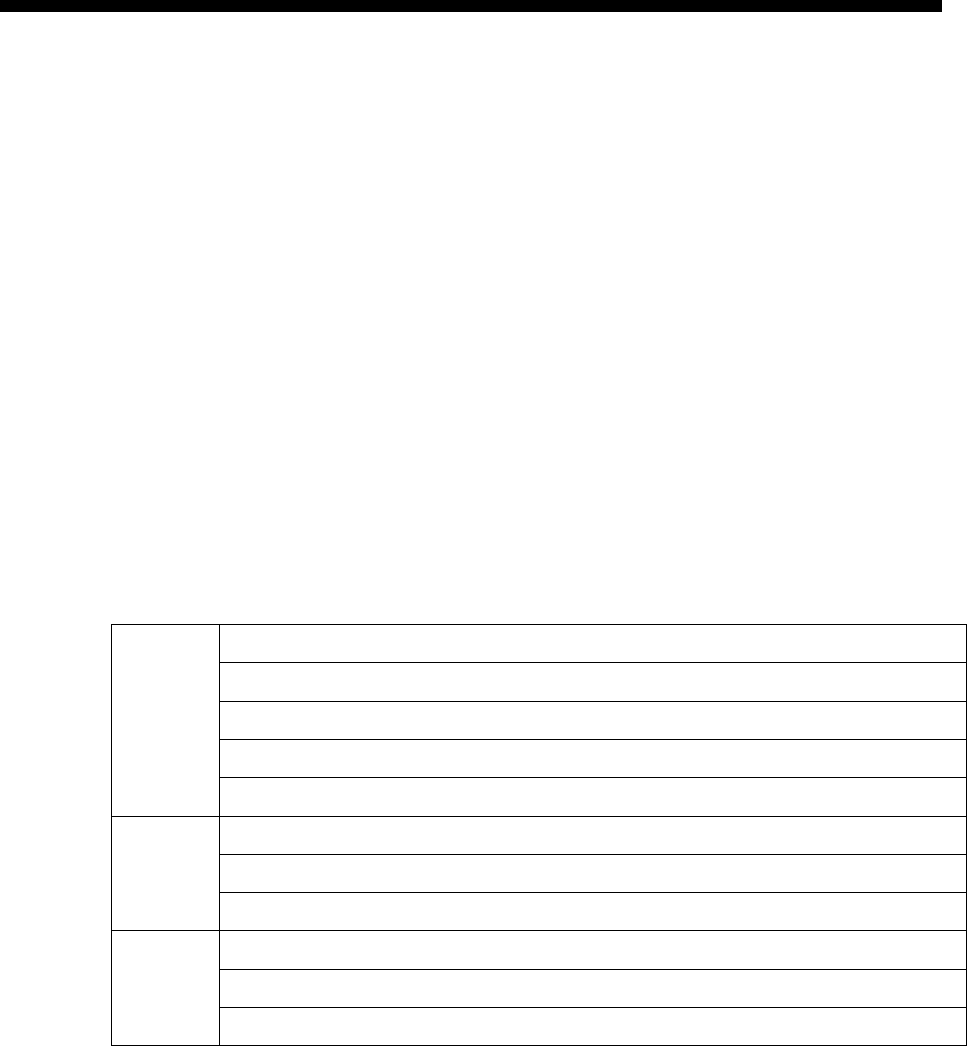

5-1 Maintenance Intervals

Check the filter for obstructions or damage when doing a material change.

Check the setting of the pressure regulator.

Empty the water separator.

Check danger signs on the unit for legibility and completeness.

Daily:

Check for worn tubing or loose electrical connections.

Clean the cartridge filter and screen (depending on accumulation of dust).

Blow out the filter from the inside using compressed air.

Weekly:

Check the electrical connections for proper functioning.

Drain the compressed air filter trap.

Check all electrical and mechanical connections.

Every 3

months:

Replace filter (depending on accumulation of dust and condition of filter).

Note:

The maintenance intervals provided are average values. The maintenance

intervals might be adjusted due to your individual process conditions.

Replace/repair components as required.