No. EJL- 106A

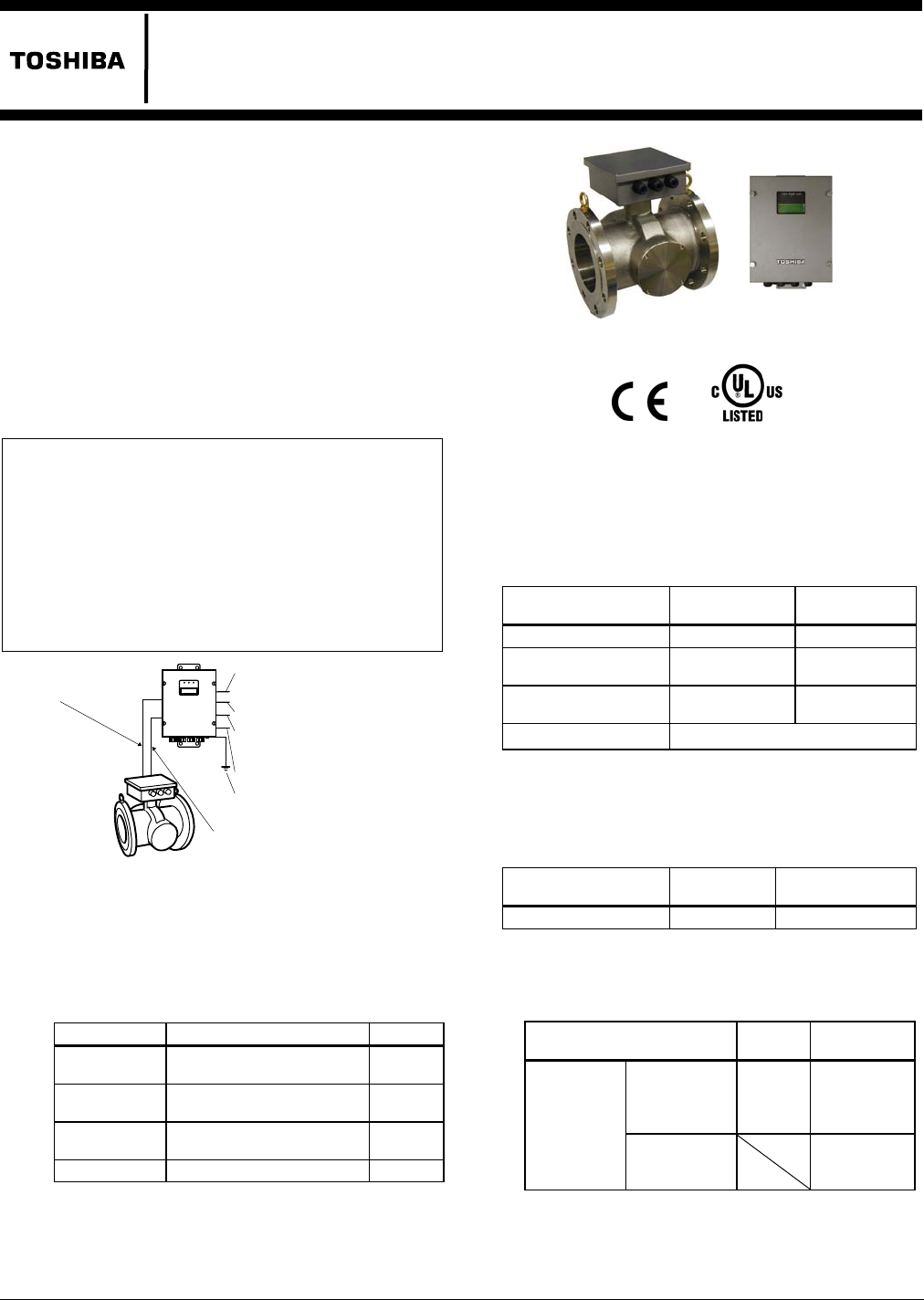

Density (Consistency) Meter LQ500

Introduction

The LQ500 density (consistency) meter uses

microwave phase shift technology to determine

concentrations of solids in the material to be measured

flowing through pipes. It can perform a stable and

realtime density (consistency) measurement because

this technology is not affected by flow velocity along

with fluid color, and also is not easily affected by

contaminants and low process pressure rate. As the

LQ500 has no moving parts, it is reliable and virtually

maintenance free.

Since the output of the LQ500 is theoretically linear, it

can be applied to a wide range of density (consistency)

measurement.

<Notice>

The LQ500 requires a full pipe to measure the

density (consistency). Contact Toshiba before

installation in the following cases:

<Possibility of unfilled condition>

(a) When it is installed at the discharge of a pump.

(b) When installation is horizontal, and unfilled

condition occurs inside the pipe.

(c) A process where the pipe becomes unfilled

when the operation is stopped.

Cable for power suppl

y

(Detector/converter)

Ground resistance

100 ohm or less

Density

(

consistency

)

measurement output 4-20mA

Cable for communication

(Detector/converter)

A

C power supply

DI / DO

External Sync control

contact in

p

ut

Figure

1. LQ500 Configuration Diagram

■

Standard Configuration

• Density (Consistency) Meter: 1 set

(Detector and converter separate mounted)

• Accessories: 1 set (see Table 1 below)

Table 1. Standard Accessories

Items Specifications Quantity

Power supply

cable

Between detector and

converter (*1)

10 m

(32.8 ft)

Communication

cable

Between detector and

converter (*1)

10 m

(32.8 ft)

Fuse

2A(T), 250 V

(glass tube, 5.2 dia. x 20 mm)

2

Document Instruction manual 1

Note 1: Need to prepare a power supply cable for the

LQ500.

Refer to the section of cable specifications at the

overall specifications in detail.

Figure 2. LQ500 Density (consistency) Meter

Specifications

■

Overall Specifications

Measurement method:

Microwave

phase difference method

Measurement

range:

Meter size 50 mm (2”)

80 to 300 mm

(3” to 12”)

Span (*2) 2 to 50 %TS (*1) 1 to 50%TS (*1)

Lower limit setting

range (4 mA)

0 to 48%TS 0 to 49%TS

Upper limit setting

range (20 mA)

2 to 50%TS 1 to 50%TS

Setting increments 0.1%TS

*1 TS: Total Solids

*2 Span = Upper range – Lower range

*3 The material to be measured must be fluid

and be filled evenly with no voids.

Repeatability:

Meter size 50 mm (2”)

80 to 300 mm

(3” to 12”)

Repeatability ±0.02%TS ±0.01%TS

Note 1 : Above values are the results of commuting ability

in the phase measurements of the converter.

Note 2 : Density (consistency) determination

repeatability for sample reagent;

Meter size

50 mm

(2”)

80 to 300 mm

(3” to 12”)

For the full

scale value of

2%TS or

greater

±2%FS ±2%FS

Density

(consistency)

determination

repeatability

For the full

scale value of

less than 2%TS

±4%FS

*The characteristics of sample reagent has errors due

to sample tests such as uneven density (consistency)

distribution.

*Full scale is the maximum value in the measurement