LQ500

6

(7) Install an adjustable piping mechanism if there

is a possibility that the detector pipe may not fit

between mating flanges.

(8) Install the LQ500 in a place where enough

water pressure is applied. Therefore, it is

recommended that the LQ500 be installed as

far away as possible from the pipe outlet

opened to atmosphere. This is to prevent the

effects of air being trapped in the liquid.

(9) If there is a possibility of no liquid flow or

uneven liquid distribution occurring when a

pump is off, use an external synch control

signal to operate the LQ500 only when the

pump is working.

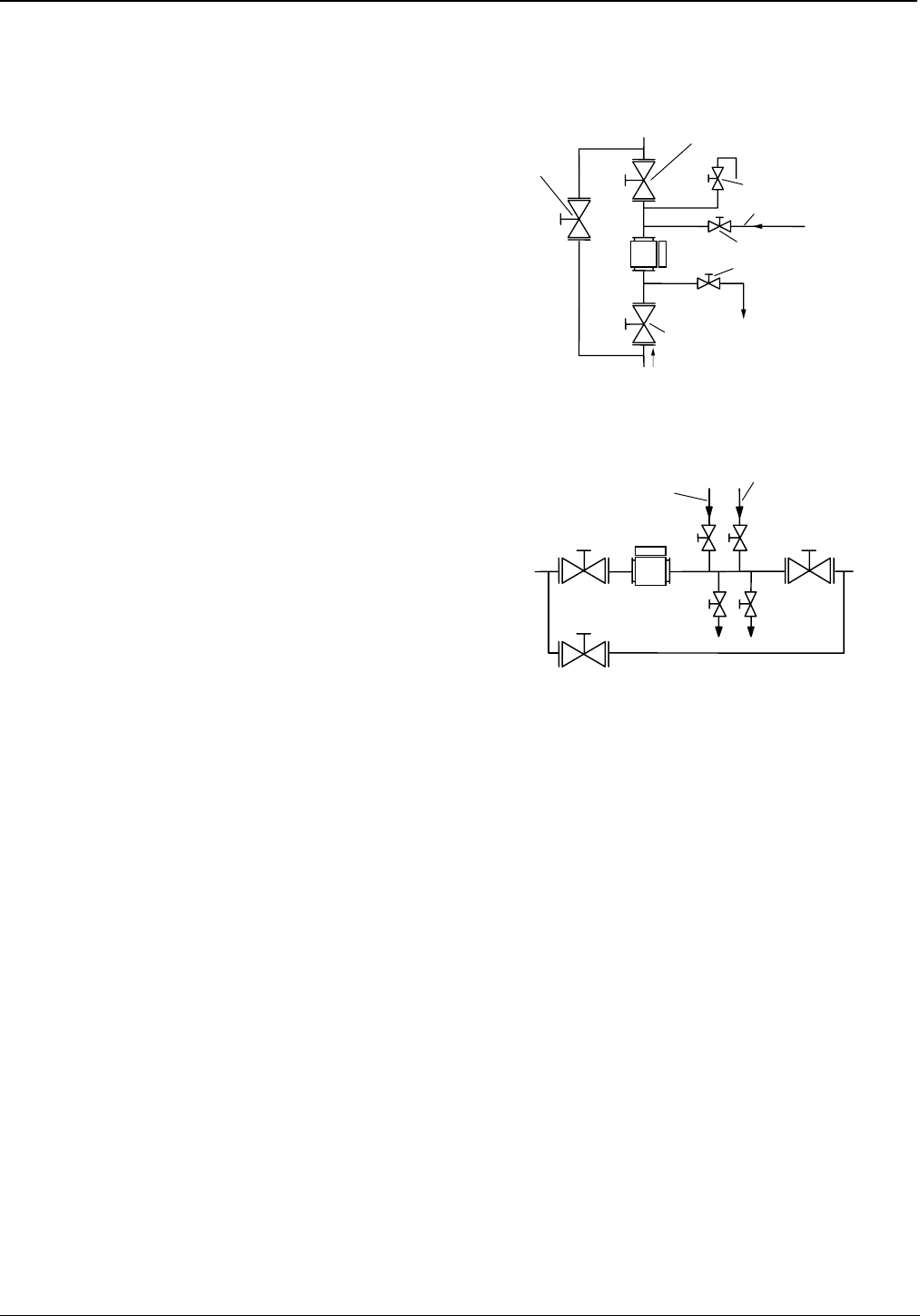

(10) Provide a stop valve at upstream and

downstream of the detector, and between stop

valves and the LQ500 provide the four valves

described below with a stop valve attached to

each: 1) sampling outlet valve; 2) zero point

water inlet valve; 3) vent valve; and 4) drain

valve. If it is not possible to stop the fluid at the

point where the LQ500 is installed, provide a

bypass pipe with a stop valve provided in the

middle. These valves are needed to drain the

fluid from the detector

pipe and fill it with

drinking water (density or consistency 0%) to

adjust the zero point. See Figures 6 and 7.

(11) Use gaskets for piping of the size conformed to

flange rating and of the material appropriate

for the liquid to be measured.

NOTE:

• Zero point water valve:

Used to supply drinking water (density or

consistency 0%) to the detector pipe for zero

point adjustment. Install this valve at the top of

the pipe in the case of horizontal installation. It

is recommended that a 1-inch ball valve be

installed on the top of the pipe and zero point

water supplied through this inlet using a vinyl

hose etc.

Note: If valve water pipe is connected to this

valve, air cannot be extracted. Therefore,

another valve (vent valve) is needed to

extract air.

• Vent valve:

Used to vent process fluids to open air when

performing zero adjustment. This helps the

drinking water (density or consistency 0%)

enter the detector pipe easily. Install this valve

on the top of the pipe in the case of horizontal

installation.

• Drain valve:

Used to drain the fluids before supplying

drinking water (density or consistency 0%) to

the detector pipe for zero adjustment. Install

this valve at the lowest point of the pipe. It is

recommended that a 1-inch ball valve be

installed at the lowest point of the pipe.

• Sampling valve:

Used to extract fluids for manual analysis.

Install this valve to the side of the pipe in the

case of horizontal installation. It is

recommended that a 1-inch ball valve be

installed to the side of the pipe.

Stop

valve

Bypass

pipe

Zero point water valve

Flow direction

(from down to up directions)

Drain pipe

V

ent valve

Drain valve

Stop valve

LQ500

Stop valve

Zero point water pipe

Figure 6. Recommended Installation

(vertical installation)

Stop valve

Vent valve

Zero point

water valve

LQ500

Stop valve

Bypass pipe

Drain

valve

Sampling

valve

Stop valve

Figure 7. Recommended Installation

(horizontal installation)

■

Wiring Precautions

(1) Provide a switch and a fuse to isolate the unit

from the mains power for ease of maintenance.

(2) Ground the LQ500 with 100 ohm or less

ground resistance. Do not use a common

ground shared by other power equipment.

(3) Use the accessorious cables for communication

and power supply between detector and

converter. Connect cables to the terminals that

match the marking on the cables.

(4) Use a sheathed cable with 2mm

2

cross-sectional area for AC power cable.

(5) The cables should be free from vibration and

should have no slack in the cables.

(6) Wire the LQ500 output in conduit separated

from those of AC power cable, control signals,

alarm signal or other cables which could

become the source of noise.

(7) Use a 2-wire shielded sheathed cable to wire

the LQ500 output (4-20mAdc) and

conductivity signal. Ground the shielded cable

on the receiving instrument side for both cable.