Page 15

EXPLANATION OF LABEL TRANSFER

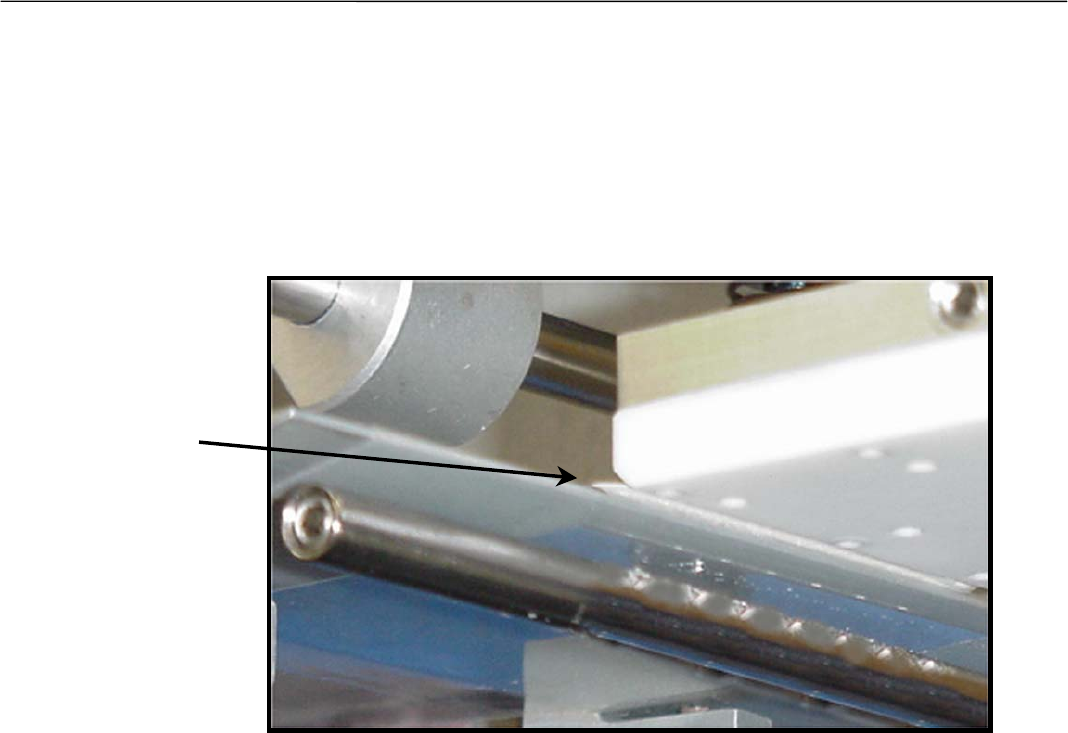

As the label is being peeled, it should first contact the center of the bevel on the

Vacuum Head. This will deflect the label slightly downward. The air from the Air

Assist Tube will keep the label up against the face of the Vacuum Head.

NOTE: The label is deflected downward so that after it is transferred to the head, it

will be resting in a position below the peeler plate edge. This is done so the label

will not contact the peeler plate edge, as it is being tamped or blown onto the

product.

With the product sensor plugged into the proper receptacle, you can cycle the

applicator by breaking the beam (photo eye) or tripping the foot switch or micro

switch in the fixture. The foot or micro switch in the fixture are used when the L60 is

operated as a semi-automatic labeling device, while a photoelectric switch is used

when the L60 is mounted in line for automatic label application. When activated, the

motor will be turned on and the air will rush through the Air Assist Tube assisting the

label transfer. The amount of air rushing through the tube is most critical to a

smooth transfer and ultimately the accuracy of the Label Applicator. All the

applicators are tested at the factory and the Air Assist Tube airflow is set at that time.

However, different label stocks react differently during the transfer process,

therefore, the following procedure should be employed if the proper label transfer

cannot be achieved.

Label

deflecting

off center

of bevel

Fig 14