Xerox Nuvera

®

100/120/144 EA Digital Production System - Customer Expectations Document

- 38 -

Temperature

heavyweight paper by means of the User

Interface.

Developer Carrier: 35 microns; Toner: 6 microns

Trickle development system

Registration Translating Electronic Registration Benchmark registration system holds image to

sheet alignment at +/- .65mm per side AND

front-to-back on Letter/A4 size papers;

+/- .75mm per side AND front-to-back on

Tabloid/A3 size papers.

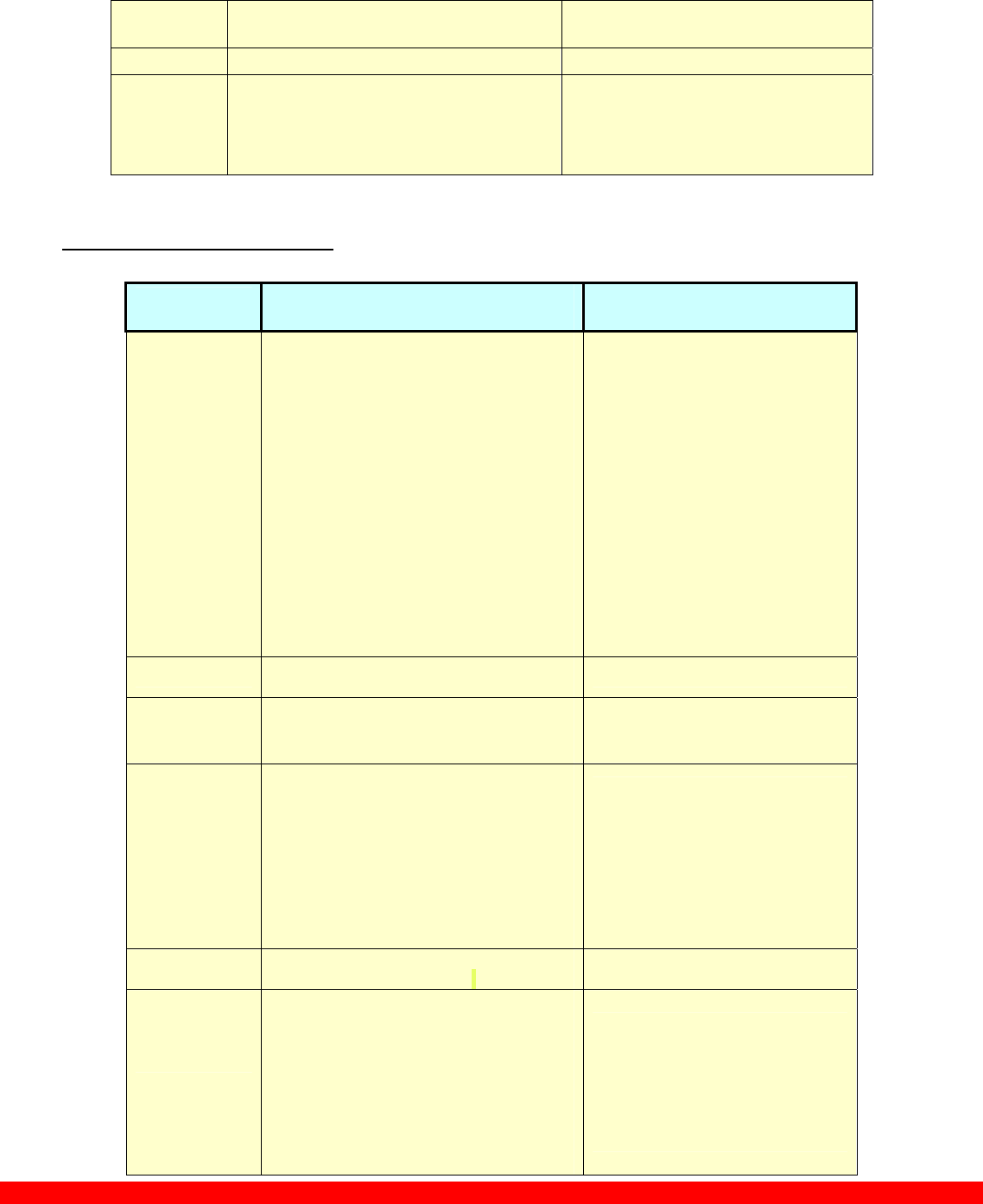

Image Quality Expectations

Image Quality

Parameter

Xerox Nuvera

®

100/120/144 EA

Digital Production System

Comment

Image Uniformity

The Xerox Nuvera

®

100/120/144 EA

Digital Production System is designed

to render tints with a high degree of

uniformity, and produce vignettes,

sweeps and gradients that are smooth

and even.

Sophisticated design prevents

unwanted process speed variations

that plague lesser digital printing

systems with banding problems.

Halftoning algorithms and customized

halftone dot designs take full

advantage of the printer’s high

addressability imaging system to

render incredibly sharp, detailed

images.

The most discriminating judges

of print quality may occasionally

perceive a degree of mottle in

large uniform flat tints.

Extremely high humidity, low

document area coverage or

papers with poor formation can

exacerbate mottle.

If excellent uniformity is required,

controlling environmental factors

or an accelerated maintenance

rate can usually satisfy

demanding customers.

Text Quality

Black text quality is excellent for sizes as small

as 4 point.

Line Quality

The Xerox Nuvera

®

100/120/144 EA Digital

Production System can print solid lines all the

way down to 70 microns.

Area Coverage

The Xerox Nuvera

®

100/120/144 EA

Digital Production System uses nested

automated controls of dry ink,

development, tone reproduction, and

the internal environment to assure

consistent printing. These closed loop

process controls continuously test

against the targets and adjust as

required.

The control system is designed to run

within a specific range of quality.

Although some variation may be

noticeable in specific cases, the closed

loop controls will typically deliver very

acceptable quality, consistently,

predictably, and without operator

intervention.

Mylar tabs

Images printed on Mylar tabs typically show

degradation due to toner scatter.

Other artifacts

As with any printing process, artifacts will occur

on the Xerox Nuvera

®

100/120/144 EA Digital

Production System. These include streaks,

mottle, banding, spots and edge deletions. For

most jobs and clients, the expected level of

artifacts is within the normal operational and

component quality ranges of the system and will

not affect the acceptability of the job.

Maintenance procedures are available

to mitigate these artifacts. Artifact-

sensitive jobs should be monitored.

Using stocks on the Recommended

Media List and maintaining your

environment will also help to minimize

the occurrence of these artifacts.