18

Operation (Continued)

Pressure Regulator (Figure 3-3)

Regulates main air pressure to the machine to

adjust pressure, pull knob up and turn; push

down to lock setting.

Filter (Figure 3-3)

Removes dirt and moisture from plant air before

it enters the case sealer pneumatic circuits. If

water collects in bottom of bowl, unscrew the

valve on the bottom of bowl to drain. When

empty, retighten valve.

Emergency Stop Switch (Figure 3-2)

The machine electrical supply can be turned off

by pressing the latching emergency stop

switch. To restart machine, rotate emergency

stop switch a quarter turn clockwise to re-

leases switch latch. Restart machine by

turning the switch to the "O" (Off) position then

to "I" (On).

Upper Drive Assembly Actuator Switch

(Figure 3-2)

This switch, when touched by the leading edge

of a box , pneumatically raises the upper drive

assembly to allow insertion of the box under

the drive belts. As the box moves under the

switch, releasing it, the upper drive assembly

descends on the box and the drive belts

convey the box through the machine. When

switch is turned, the upper drive assembly

rises. When the switch is released, the upper

drive assembly descends to its rest position.

Centering Guide Switch (Figure 3-7)

This pneumatic switch controls the box

centering guides. When switch is activated by

a box entering the case sealer, the centering

guides close (centering the box), and released

(after box passes over switch), the guides

open.

Air Pressure Regulator, Centering Guide

Force Adjustment (Figure 3-4)

This regulator is used to adjust centering

guides according to weight of boxes. Pressure

should be adequate to center boxes, but low

enough to allow easy pushing of boxes under

taping head.

To adjust the regulator setting, pull the knob

outward, rotate the knob to the desired setting.

Push the knob inward to lock it and prevent

unintentional adjustment.

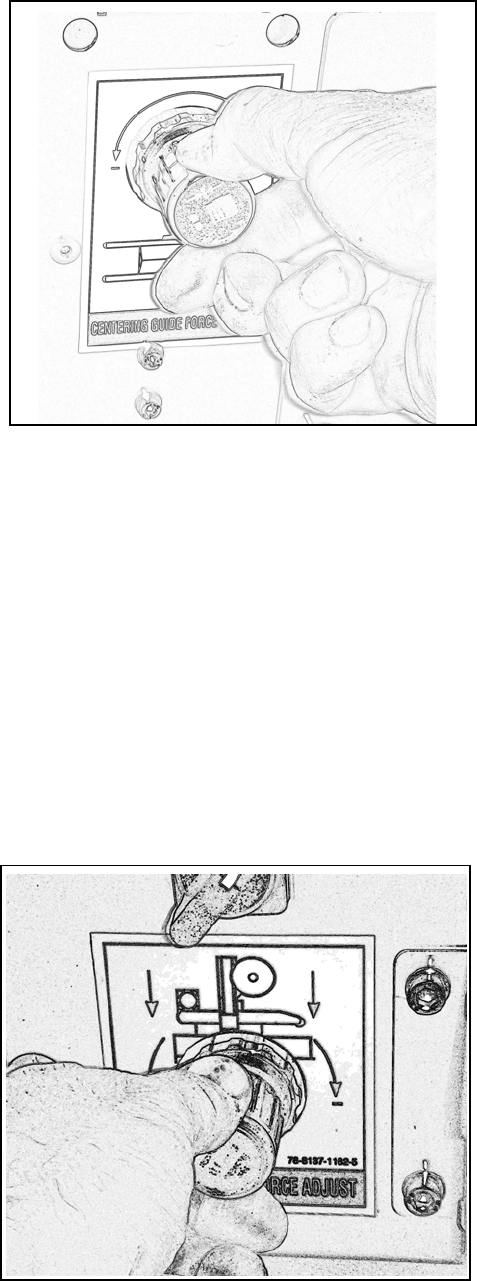

Figure 3-5—Air Regulator/Gauge, Top Drive

Assembly

Figure 3-4—Air Regulator, Centering Guides

Air Pressure Regulator, Top Drive Assembly

Force Adjustment (Figure 3-5)

Set nominally to control the "down" movement of

top drive assembly and the pressure exerted

against the box as shown in Figure 3-5. The

regulator setting is changed as necessary for the

boxes being sealed to provide adequate drive belt

pressure against the box to positively convey the

boxes through the machine. If the boxes stop or

hesitate while being conveyed, decrease the

regulator pressure. This increases the drive belt

force on the box for more friction between the box

and drive belts. Adjust the pressure setting as

necessary to get continuous movement of boxes

through the machine.