11 - SET UP AND ADJUSTMENTS (continued)

31

One Way

Tension

Roller

Tension

Wrap

Roller

Knurled

Roller

Wrap

Roller

Applying

Roller

Threading

Needle

#1

#2

#3

#4

Figure 11-8

2012 March

800rf-NA

Important – If drive belts are allowed to slip on

box, excessive belt wear will occur.

Note - For belt replacement and tension

specifi cations - refer to Section 13 /

Maintenance and Repairs).

• To reduce the risk associated with

pinches hazards:

− Keep hands clear of the upper head

support assembly as boxes are

transported through the machine.

− Keep hands, hair, loose clothing, and

jewelry away from box compression rollers.

− Always feed boxes into the machine by

pushing only from the end of the box.

− Keep hands, hair, loose clothing, and jewelry

away from moving belts and taping heads.

CAUTION

1

2

Figure 11-7

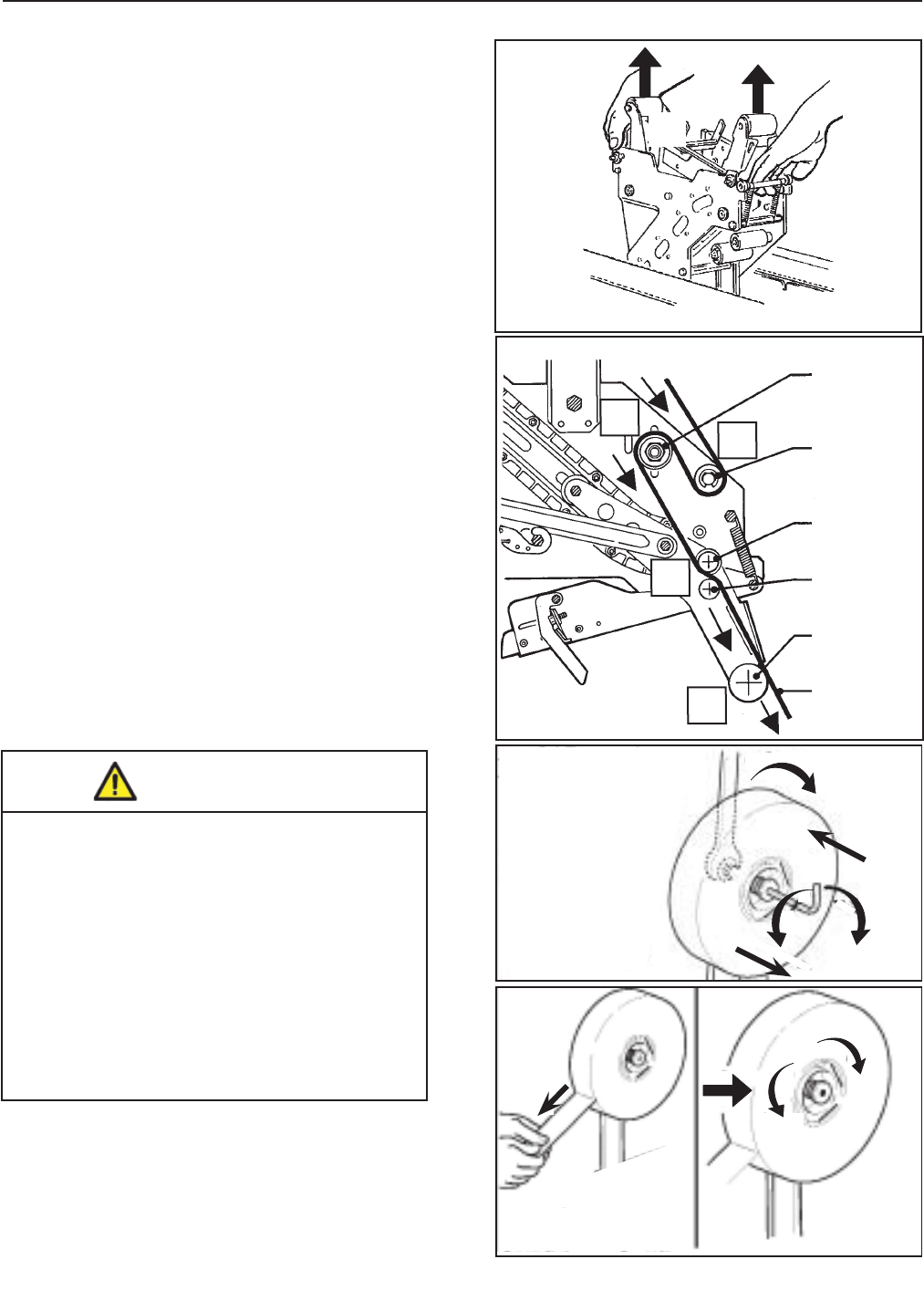

11.2 Tape Loading on the Bottom Unit

Remove the bottom taping unit from its housing and

put it on a working bench (Figure 11-7).

- Put a tape roll on the drum and thread the tape

through the unit as shown on the label in the

same manner as for the top unit (Figure 11-8).

- Put the bottom unit back into its housing.

11.3 Tape Drum Alignment

Check the centering of the tape on the rollers of

the taping unit. If necessary unscrew the nut 1 and

adjust the screw (2) (Figure 11-9).

11.4 Tape Drum Friction Brake Adjustment

Check the tape tension:-with PVC the tape drum

must be free-with OPP the tape drum must be

slightly frictioned

11.5 Adjustment of Taping Units According to

the Type of Boxes

Adjust the main spring:-decrease the spring load

for light boxes;-increase the spring load for heavy

boxes (Figure 11-10).

Figure 11-9

1

2

+

_

Figure 11-10