UNINET IMAGING INC. • BROTHER HL 2030/TN 350 CARTRIDGE REMANUFACTURING INSTRUCTIONS

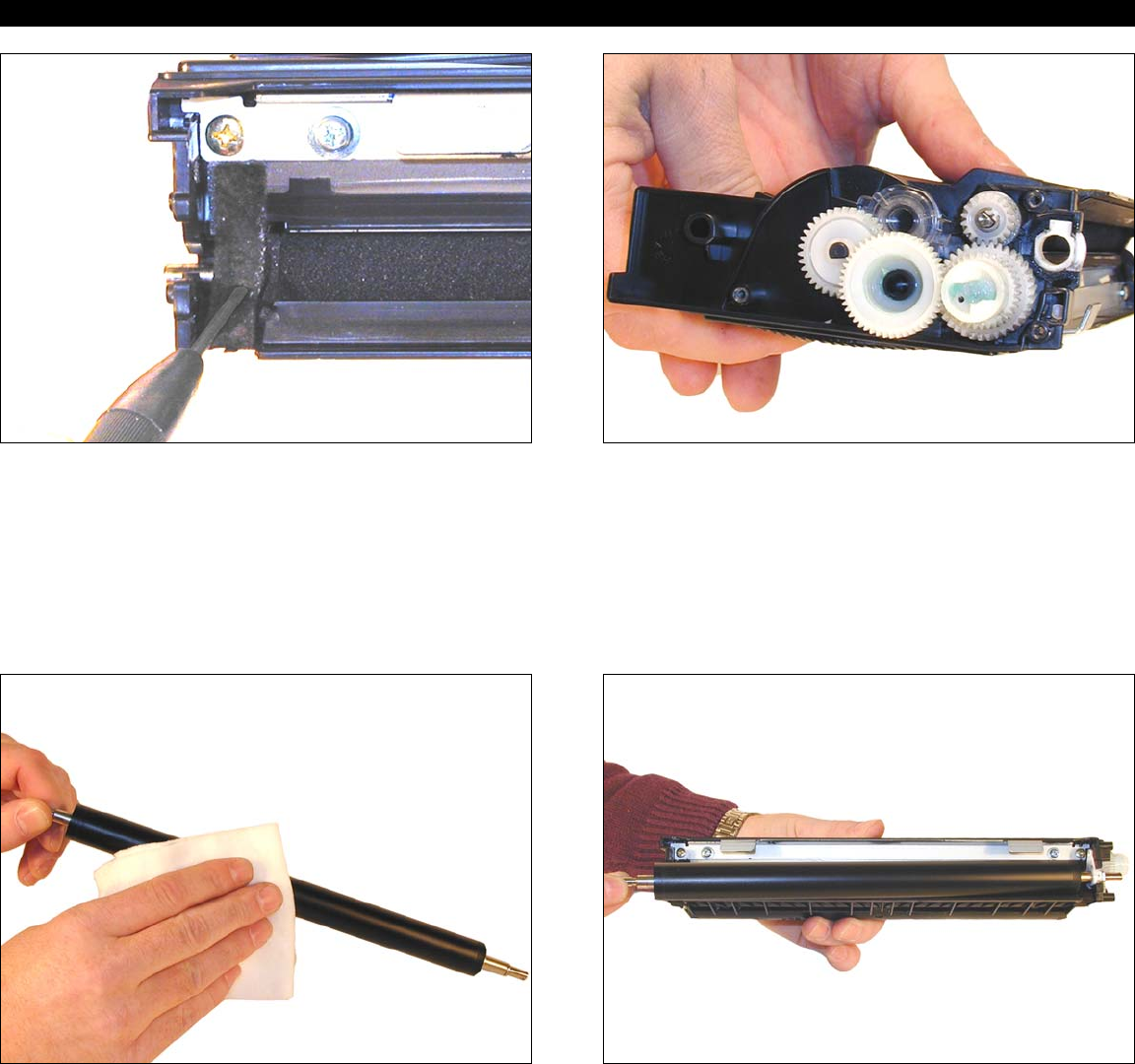

11. Inspect the magnetic roller felts. If they are compressed,

(shiny) rough them up with a small screwdriver.

12. Clean the gears, making sure that they have no toner on

them. This is a good time to also check the gear shafts to make

sure there is enough grease. If the shafts appear dry, or the

grease is contaminated with toner, clean the shaft and inside of

the gear. Replace the grease with white lithium grease.

© 2007 UniNet Imaging Inc. All Trademark names are property of their respective owners. Product brand names mentioned are intended to show compatibility only. UniNet Imaging does not guarantee or warrant downloaded information.

www.uninetimaging.com/technical.asp

11124 Washington Blvd., Culver City, California USA 90232 • Ph +1 310 280 9620 • Fx +1 310 280 0533 • techsupport2@uninetimaging.com

13. Clean the developer roller with a lint free cloth. Do not use

any chemicals other than a dedicated cleaner for Brother rollers

to clean the roller. A dry clean cloth will work fine.

14. Re-install the developer roller long shaft side to the gear

side.